Many manufacturing companies struggle with inconsistent quality across different production sites. This variance creates significant operational challenges. Artificial intelligence (AI) offers a powerful solution. AI establishes a single source of truth for quality standards.

The AI system analyzes production data from all locations. It creates a universal quality baseline. This allows for the use of real-time data to spot deviations instantly.

This process, combining advanced AI and automation, enforces uniform standards everywhere. Manufacturers can achieve consistent results by using AI. This intelligent approach transforms manufacturing operations.

The Impact of AI in Manufacturing Quality

Artificial intelligence is reshaping the manufacturing industry. It moves quality management from a reactive model to a proactive one. Instead of finding errors after production, AI in manufacturing predicts and prevents them. This shift fundamentally improves operational efficiency. While automation is powerful, human oversight remains essential. Experts must validate AI outputs and make strategic decisions, ensuring the technology serves business goals.

Achieving Real-Time Defect Detection

AI systems excel at identifying product defects instantly. Using AI, manufacturers can analyze real-time data from production lines. This process spots imperfections like cracks or scratches with incredible accuracy. Some companies have seen a 50% reduction in defect rates after implementing these systems. This advanced quality control reduces scrap and rework, directly boosting Overall Equipment Effectiveness (OEE). Better defect detection leads to higher-quality products and less waste.

Enforcing Consistent SOPs and Standards

AI ensures that all teams follow Standard Operating Procedures (SOPs) correctly. AI in manufacturing uses computer vision to monitor workflows across different locations. This technology provides a new level of control and consistency.

- It verifies that workers complete every step in a process.

- It confirms employees wear the correct safety gear.

- It creates detailed audit trails for compliance.

This constant monitoring helps standardize operations, a key challenge in the manufacturing industry. AI-powered solutions ensure every site adheres to the same high standards, which also benefits supply chain management.

Reducing Inspection Bottlenecks

Manual inspections often slow down production. AI automation breaks through these bottlenecks. AI-powered inspection is much faster and more consistent than human checks. For example, one electronics manufacturer increased its throughput 6X by replacing manual inspection with an AI system. This efficiency allows for 24/7 quality monitoring without fatigue.

By processing data at high speeds, AI eliminates delays. This allows the entire manufacturing process to run more smoothly, increasing overall output and improving the quality of the final product. The use of AI in manufacturing transforms the entire inspection workflow.

Core AI Technologies for Standardization

Core AI technologies provide the engine for manufacturing standardization. These tools transform raw data into actionable insights, creating a unified quality control framework. They are essential for modernizing the manufacturing industry.

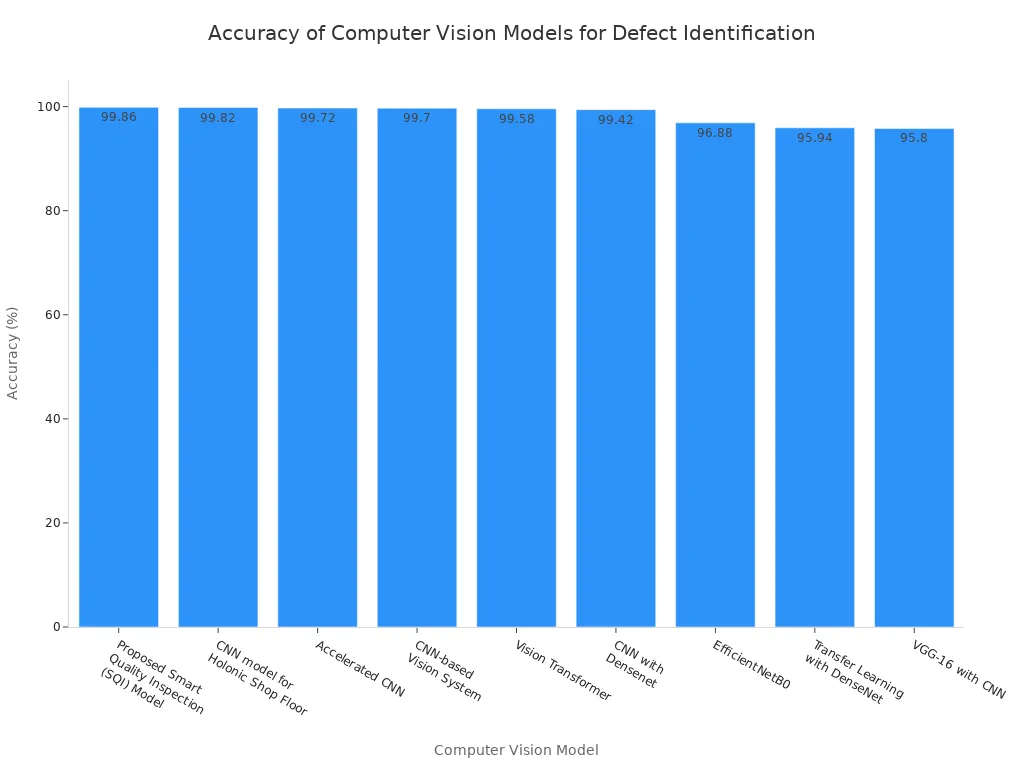

Computer Vision for Universal Inspection

Computer vision gives machines the power of sight. This AI technology automates visual inspection with superhuman accuracy and consistency. Human inspectors have a mistake rate between 10% and 20%. In contrast, modern AI vision systems achieve over 99% accuracy. For example, Volvo Cars uses an AI inspection system that finds 10% to 40% more defects than manual methods. This technology is vital for quality control in the manufacturing industry. Automation and robotics powered by computer vision ensure every product meets the same high standard.

Predictive Analytics for Process Control

Predictive analytics uses sensor data to forecast problems before they happen. This AI technique analyzes real-time information like temperature and vibration. It identifies patterns that signal potential equipment failure or process deviations. This enables predictive maintenance, allowing teams to fix issues proactively. The aerospace industry saw a 30% reduction in defects using ai in manufacturing for predictive control. This approach turns reactive maintenance into a proactive strategy, boosting efficiency and ensuring consistent output in manufacturing. The use of predictive analytics is a game-changer for process control.

NLP for Standardizing Unstructured Data

Natural Language Processing (NLP) helps standardize unstructured data like operator notes and maintenance logs. This AI technology reads and understands human language. It extracts key terms, identifies equipment, and categorizes maintenance issues automatically.

This process creates clean, uniform data across all sites, even with different languages or terminology. Better data leads to smarter predictive maintenance and improved supply chain management. NLP is a powerful tool for any manufacturing operation seeking true standardization. The analytics derived from this data helps refine processes.

Implementing a Standardized Quality System Using AI

Implementing a standardized quality system using ai is a structured process. It transforms manufacturing operations from fragmented to unified. This guide outlines a clear, four-step journey for creating a single source of truth for quality across all production sites. Following these steps helps organizations achieve consistent excellence and boost operational efficiency.

Step 1: Centralize and Standardize Data

The first step is to create a centralized data foundation. All quality-related information from different sites must flow into a single repository, often a data lake. This process breaks down data silos. It provides a complete view of production performance. Strong data governance is essential for success.

A well-designed data lake organizes information into zones like raw, enriched, and curated. This structure supports better analytics and decision-making. It also enables teams to standardize skills data and optimize skills data for effective skills management.

Best practices for building this central system include:

- Establish Strong Governance: Define clear roles like data owners and stewards. Create policies for data validation, security, and compliance. This ensures data quality improvements from the start.

- Implement Robust Access Control: Use Role-Based Access Controls (RBAC) to manage user permissions. This protects sensitive information and ensures security.

- Choose Optimal Data Formats: Select formats like Parquet for read-heavy analytics. This choice improves query performance and efficiency.

- Use a Data Catalog: A centralized catalog helps users find and understand available data. It improves data discovery and reuse across the organization.

Step 2: Develop and Train a Global Model

After centralizing data, the next step is to build a global AI model. This model acts as the universal standard for quality. It learns from the combined data of all manufacturing sites. The goal is to create a master algorithm that understands every possible defect and process variation. This AI becomes the core engine for your quality control system.

Engineers use various machine learning algorithms for this task. The choice depends on the specific manufacturing needs. Common deep learning technologies for defect detection include:

- Object Detection Models: Algorithms like YOLO (You Only Look Once) and SSD (Single Shot Detector) excel at identifying and locating defects on products in real-time.

- Image Segmentation Models: Techniques like U-Net can precisely outline the exact shape and size of a defect. This provides detailed analytics for root cause analysis.

This global model provides a consistent baseline for quality. It ensures that the definition of a "flawless" product is the same everywhere. The AI model's predictive capabilities also support better maintenance planning.

Step 3: Deploy and Calibrate Locally

A global model needs local adaptation. The third step involves deploying the AI system at individual manufacturing sites and fine-tuning it. Each factory has unique conditions, such as different lighting, equipment, or local materials. The AI model must be calibrated to account for these specific variables. This ensures high accuracy in a real-world environment.

A phased rollout is the most effective strategy. It allows teams to learn and adjust without disrupting the entire supply chain management. Many leading companies have seen great success with this approach. Their results demonstrate the power of AI in manufacturing.

| Company | AI System Implemented | Key Outcomes |

|---|---|---|

| Bosch | Machine learning for surface defect inspection | 25% reduction in scrap rate and a defect detection accuracy increase from 89% to 97.6% |

| Foxconn | AI-powered visual inspection for smartphones | Real-time detection of microscopic scratches and misaligned components, improving quality consistency |

| Samsung | AI-powered computer vision for wafer alignment | 8-10% yield improvement and reduced defect-related rework, strengthening product reliability |

Step 4: Create a Continuous Learning Loop

The final step ensures the AI system remains effective over time. Manufacturing environments are dynamic. New products are introduced, processes change, and new defect types can appear. A continuous learning loop keeps the AI model up-to-date. This process uses a technique called transfer learning.

Transfer learning allows the AI to learn from new data without starting from scratch. When the system encounters a new defect, operators can label it. This new information is used to retrain and update the global model. This approach saves significant time and resources. It makes the AI smarter with every production cycle. This loop transforms the quality system into a living, evolving entity that drives continuous improvement, better predictive maintenance, and smarter analytics. This automation helps optimize skills data and maintain high standards.

Overcoming Deployment Challenges in Manufacturing

Deploying an AI-powered quality system presents unique challenges. Leaders in the manufacturing industry must navigate data fragmentation, outdated technology, and workforce resistance. A strategic approach turns these obstacles into opportunities for growth and improved efficiency. Success requires careful planning and execution across technology and people.

Challenge: Data Silos and Inconsistency

Data silos trap critical information in separate systems like ERP and MES. This fragmentation creates problems, including inconsistent skills data that hinders workforce management. It prevents a unified view of operations. The solution is to break down these barriers and create a single source of truth.

- Establish Governance: Strong data governance defines ownership and sets quality standards from the start.

- Integrate Tools: Modern ETL (Extract, Transform, Load) tools unify data from different sources into a central data warehouse.

- Automate Pipelines: Automation ensures a continuous flow of clean data, correcting discrepancies and filling in missing values.

This process provides the clean, centralized data needed for effective AI implementation in manufacturing.

Challenge: Integrating Legacy Systems

Many manufacturing facilities rely on older systems like SCADA and PLCs. These legacy systems often lack compatibility with modern AI platforms. Integrating AI can enhance their functionality, but it introduces challenges like data quality issues and cybersecurity risks. The goal is to augment, not just replace. AI integration enables predictive maintenance, which reduces equipment downtime and operational costs. This approach transforms vast amounts of system data into actionable insights for better decision-making. It allows companies to upgrade their capabilities with automation and robotics without a complete overhaul.

Challenge: Fostering Team Buy-In

Employees may fear that AI will replace their jobs. This concern can lead to resistance and slow adoption. Effective change management is crucial for gaining team support. Leaders should address these fears directly, framing AI as a tool that enhances human skills, not a replacement. Treating employees as co-creators in the new workflow builds trust. Upskilling programs that provide technical training for new AI tools and robotics empower the workforce. Successful AI in manufacturing projects often have strong executive support and clear communication. This fosters a culture where teams see AI as a partner in improving quality, maintenance, and overall supply chain management.

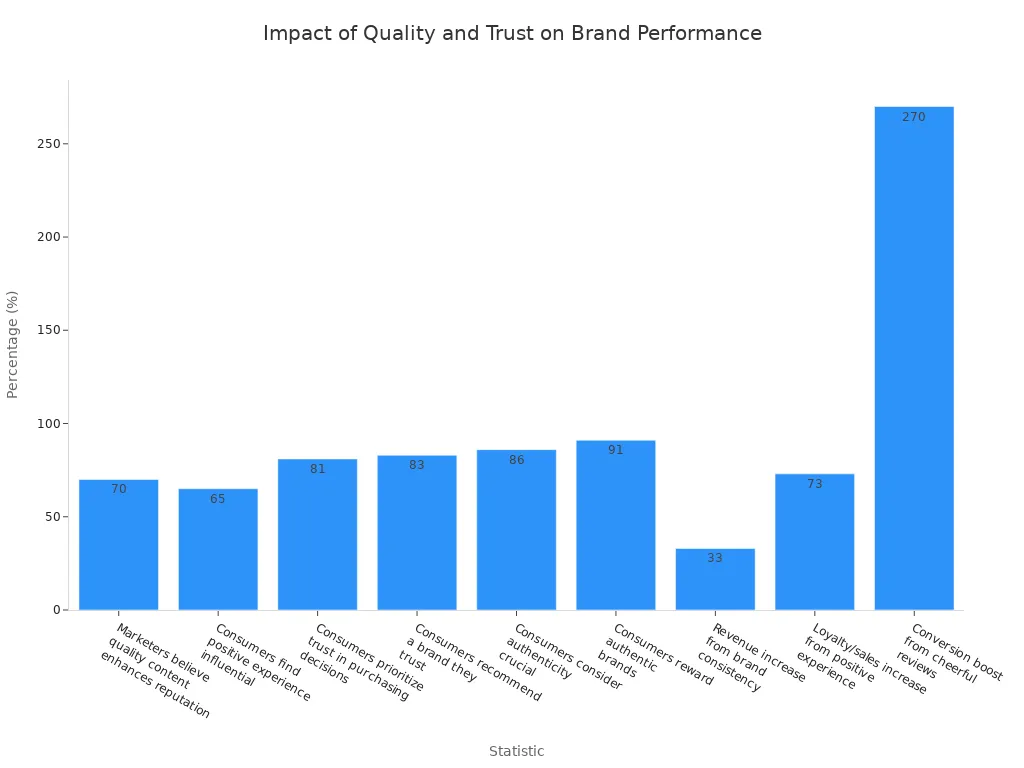

AI creates a dynamic system that actively enforces uniform quality, moving beyond simple monitoring. This centralized approach provides the definitive solution to site-to-site variance in manufacturing. It empowers leaders to make consistent data-driven decisions.

Using ai to achieve predictable, flawless production directly strengthens brand reputation and customer trust. As future trends like generative ai continue to evolve, this technology will further revolutionize manufacturing, ensuring superior quality and a stronger global market position.

FAQ

How long does AI implementation take?

AI system implementation timelines vary. A typical project takes several months. The schedule depends on data readiness and system complexity. A phased rollout helps manage the process effectively and minimizes operational disruption.

Does AI replace human inspectors?

AI does not replace human inspectors. It acts as a powerful tool. The technology handles repetitive tasks. This allows employees to focus on complex problem-solving and system validation, enhancing their roles.

What data does the AI need for training?

The AI requires a large dataset for training. This includes images of both good products and defective ones. Sensor data from the production line also helps the model learn process parameters and identify patterns.

How does AI handle new defects? ⚙️

AI systems use a continuous learning loop. Operators can label new, unseen defects. The system then uses this information to retrain the global model, improving its accuracy and knowledge over time.

See Also

AI-Powered Production Forecasting: 2024 Enterprise Strategies for Superior Accuracy

Achieving Peak Efficiency: AI-Driven Just-In-Time Delivery by 2025

Optimizing Operations: AI-Powered Demand-Driven Production Scheduling for 2025

Sustainable Style: Innovative AI Solutions Transforming Fashion for Good

Delighting Consumers: Smart Machine Learning Elevates the Ordering Experience