The future of computer vision in fabric inspection is a shift toward predictive, autonomous quality control. Advanced AI drives this change in textile manufacturing. This AI improves the visual inspection system. Current automated systems struggle with subtle defect detection. AI-powered machine vision for defect detection solves these issues. This automation provides real-time quality control. AI uses images and data for better detection. AI enhances quality and precision.

AI offers superior accuracy in defect detection.

- Manual visual fabric inspection misses 10-40% of fabric defects.

- AI inspection achieves over 85% accuracy in real-time defect detection.

The growing market for automated inspection shows industry trust in AI. This AI technology supports better quality control processes. Real-time data from images enables this control. AI makes zero-defect textiles a tangible goal for textile manufacturing. This AI-driven efficiency transforms textiles production.

The Evolution of Computer Vision in Textiles

Limits of Manual and Basic Automated Detection

Traditional fabric inspection relies on human sight, a method with significant drawbacks. Manual detection is slow and labor-intensive. Human inspectors experience fatigue, which reduces accuracy over long shifts and leads to inconsistent quality control. This subjectivity often results in missed fabric defects. Early automated inspection systems offered an alternative but had their own failures. These first-generation tools struggled with the precision needed for modern textiles manufacturing. Their machine vision for defect detection often failed to identify small or subtle defect types. For example, the detection accuracy for issues like a broken pick was low due to image noise. Furthermore, the processing speed of this early automation was too slow for a real-time production line, making it impractical for high-volume manufacturing.

The Vision for Autonomous Quality Control

The future vision moves beyond simple automation to autonomous quality control, powered by advanced AI. This new paradigm uses a sophisticated visual inspection system. AI transforms the process from reactive to proactive. The goal of AI is not just better defect detection; it is complete process optimization. This AI uses vast amounts of images and data to train its models. The result is superior precision and real-time defect detection.

The power of AI lies in its ability to learn and adapt. An AI analyzes images and data to improve its own detection capabilities continuously, ensuring consistent quality and efficiency.

This AI-driven approach enables immediate action on the factory floor. When the computer vision system identifies a defect, the AI can instantly analyze the data. This AI provides insights to adjust machinery, preventing further errors. AI in machine vision delivers the speed and precision necessary for modern textiles production. This level of control makes zero-defect textile manufacturing a realistic objective. The integration of AI provides the data needed for superior quality and smarter manufacturing. This AI ensures every textile meets the highest standard of quality.

Core Technologies Driving the Future

The transformation of textile inspection hinges on a suite of powerful technologies. These innovations work together to create an intelligent, responsive, and precise quality control system. They represent the engine driving the industry toward autonomous manufacturing.

The Role of AI and Deep Learning

Artificial intelligence (AI) is the core intelligence powering next-generation inspection. Deep learning models, a subset of AI, analyze vast datasets of fabric images. They learn to identify and classify defects with incredible precision. This AI-driven process far surpasses human capabilities in speed and consistency. The AI continuously improves its detection skills by processing more images and data.

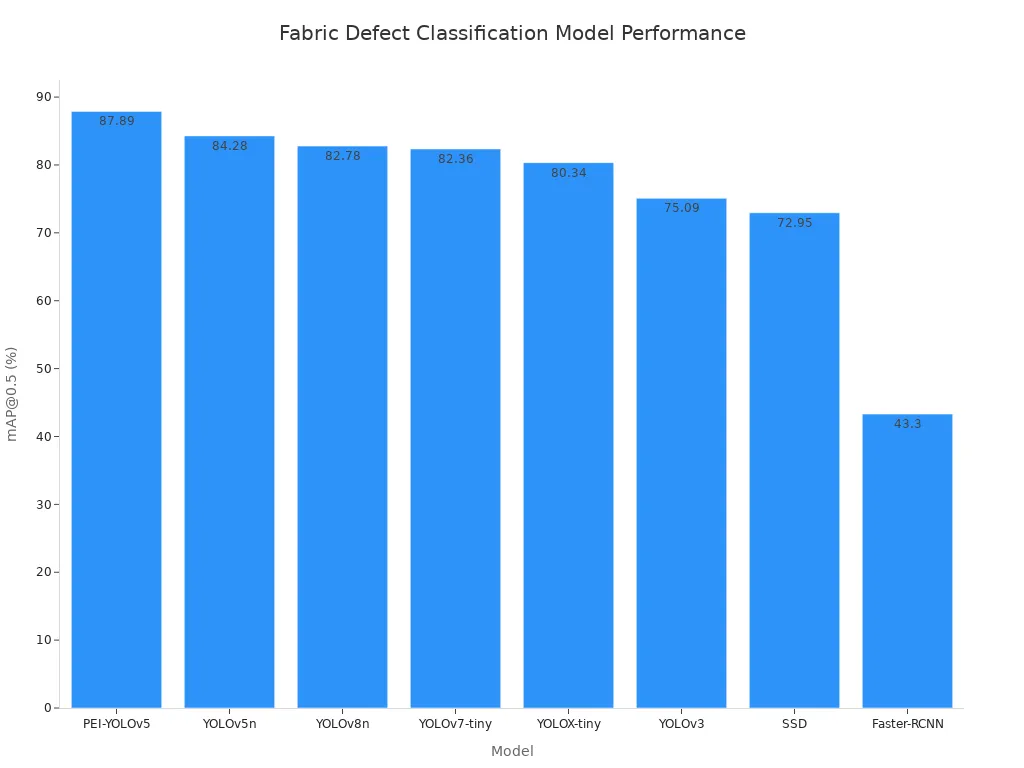

Convolutional Neural Networks (CNNs) are particularly effective for this task. These models mimic the human visual cortex. They excel at recognizing patterns in images, making them ideal for defect detection. Different models offer unique advantages in accuracy and computational efficiency.

| Model | mAP@0.5 (%) | GFLOPs |

|---|---|---|

| PEI-YOLOv5 | 87.89 | 0.2+ |

| YOLOv8n | 82.78 | Low |

| YOLOv7-tiny | 82.36 | Low |

| YOLOX-tiny | 80.34 | Low |

| YOLOv5n | 84.28 | Low |

| YOLOv3 | 75.09 | High |

| SSD | 72.95 | High |

| Faster-RCNN | 43.3 | N/A |

Note: GFLOPs for PEI-YOLOv5 are a 0.2 GFLOPs increase over YOLOv5n. 'Low' and 'High' are relative values.

To train these powerful AI models, a large volume of defect images is necessary. However, some fabric defects are rare. Generative Adversarial Networks (GANs) solve this problem.

- GANs are a type of AI that creates new, synthetic images.

- These synthetic images mimic real defect examples.

- This technique augments training datasets, giving the AI more examples to learn from.

- This approach improves the detection robustness of the AI, especially for uncommon defect types.

This use of AI ensures the system can detect and classify a wide range of issues, leading to higher quality textiles. The AI provides the data needed for superior quality and smarter manufacturing.

Advanced Machine Vision for Defect Detection

Advanced machine vision for defect detection provides the "eyes" for the AI system. This hardware captures the high-quality images necessary for accurate analysis. Without clear images, even the best AI model will fail. Automated inspection methods using this technology achieve a success rate over 90%, a significant improvement over the 60-70% rate of manual inspection. Key components include:

- High-Resolution Cameras: Line scan cameras are specialized for moving fabrics. They capture images line by line across the entire textile width. This process enables continuous, distortion-free inspection at high speeds.

- Specialized Illumination: Proper lighting is critical. Systems use diffuse, backlighting, or strobe lighting to enhance contrast and make every defect visible in the captured images. This ensures the AI has the best possible images for analysis.

- Optical Filters: These filters help isolate specific features. They can block certain light wavelengths to remove background noise or enhance the visibility of a particular defect type.

This combination of hardware and AI in machine vision creates a powerful tool for real-time defect detection. It delivers the precision and speed required for modern textile manufacturing. The automation provides the foundation for consistent quality control.

Hyperspectral and Multispectral Imaging

Some fabric issues are invisible to the naked eye or standard cameras. Hyperspectral and multispectral imaging systems see beyond the visible spectrum. These technologies analyze a material's properties based on how it reflects light, enabling a deeper level of quality control. This is especially important for defect detection in technical textiles.

What's the difference? While both technologies capture data from multiple light bands, hyperspectral imaging is far more detailed. It captures hundreds of narrow bands, creating a unique spectral "fingerprint" for each material.

| Feature | Multispectral Imaging | Hyperspectral Imaging |

|---|---|---|

| Number of Bands | 3 to 10 broad bands | Hundreds of narrow, continuous bands |

| Spectral Resolution | Lower | Much higher |

| Data Volume | Smaller, easier to process | Larger, requires more processing |

| Application in Fabric | General overview, color check | Differentiate material blends, identify chemical stains |

This technology allows an AI to identify issues like incorrect fiber blends, chemical contamination, or uneven dye application. Several companies, including HySpex, Resonon, and ProPhotonix, already provide hyperspectral systems for industrial use, particularly in textile sorting and recycling. This advanced detection capability is crucial for producing high-performance textiles with guaranteed material quality.

Edge AI for Real-Time Defect Response

Speed is essential in textile manufacturing. A defect must be addressed the moment it occurs to prevent widespread waste. Edge AI makes this possible. Instead of sending massive amounts of image data to a distant cloud server, Edge AI processes information directly on a device located at the production line. This on-device processing enables real-time image processing and immediate decision-making.

The benefits of Edge AI over cloud-based processing are significant for a factory floor.

| Feature | Cloud-Based AI | Edge AI |

|---|---|---|

| Latency | Higher (data transfer delay) | Lower (local processing) |

| Bandwidth | Requires high bandwidth | Reduces bandwidth needs |

| Reliability | Depends on network connection | Operates without a network |

| Real-time Action | Challenging due to delay | Ideal for immediate response |

This real-time capability transforms quality control from a passive to an active process. When the computer vision system spots a defect, the Edge AI can instantly trigger an action. For example, it can stop a loom to prevent a yarn break from ruining meters of textile. This immediate response minimizes waste, improves efficiency, and brings the textile industry closer to zero-defect production. The AI in machine vision, powered by edge computing, provides the ultimate control over the manufacturing process.

Revolutionizing Textile Manufacturing

Advanced computer vision technologies do more than just find fabric defects; they revolutionize the entire textile manufacturing process. This automation transforms quality control from a reactive step into a proactive, data-driven strategy. The integration of AI creates a smarter, more connected, and highly efficient production environment. This new approach to manufacturing makes near-perfect quality a tangible goal.

Achieving Near-Perfect Quality

The pursuit of "zero-defect" textiles is now a realistic objective. AI in machine vision provides the precision and consistency that manual inspection cannot match. An AI system works tirelessly, maintaining high accuracy across the entire production line. This constant quality control ensures every meter of textile meets the highest standards. The AI uses high-resolution images for superior defect detection. This level of automation significantly boosts manufacturing efficiency and quality.

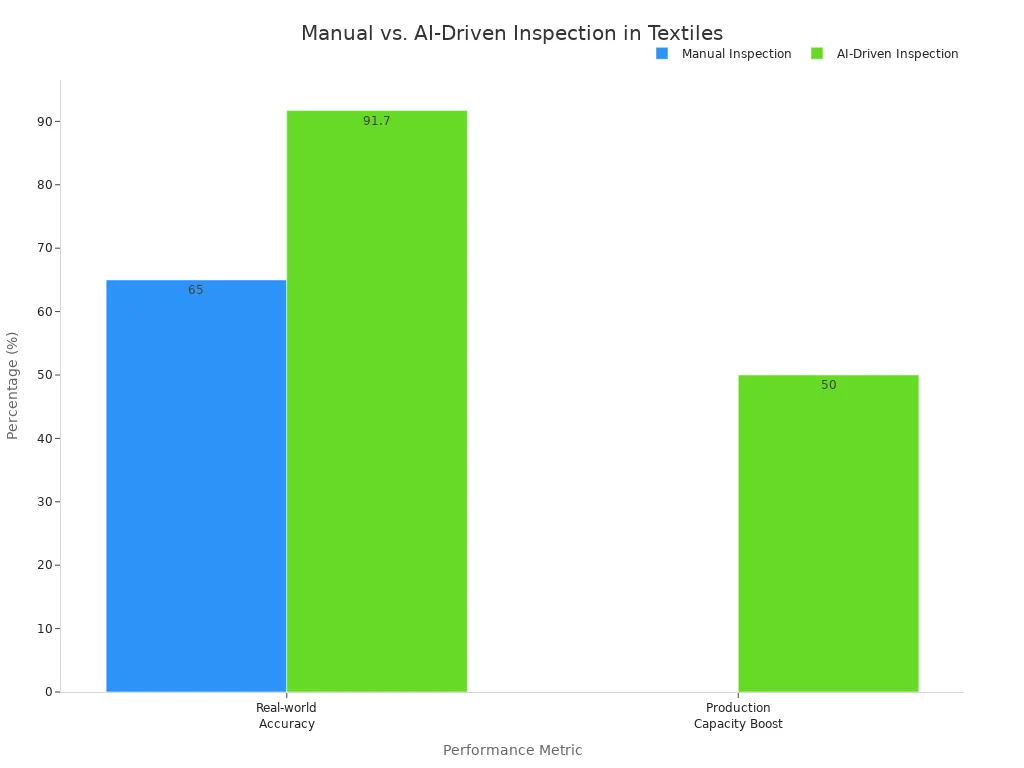

| Aspect | Manual Inspection | AI-Driven Inspection |

|---|---|---|

| Real-world Accuracy | ~65% (due to fatigue) | >90% detection rate |

| Waste Contribution | Contributes to 25% of textile waste | Reduces waste by identifying defects early |

| Production Capacity | N/A | Boosts capacity by up to 50% |

The superior accuracy of AI-powered detection is clear. This advanced quality control helps manufacturers deliver flawless textiles.

Predictive Analytics for Process Optimization

The true power of AI lies in its ability to use data for predictive insights. The system moves beyond simple real-time defect detection. An AI analyzes data from thousands of images to identify patterns. This data helps predict when a machine might fail or when a process needs adjustment. For example, if the AI detects a recurring defect, it can trace the data back to a specific machine setting, like incorrect warp tension. This allows operators to fix the root cause before it creates more waste. This proactive approach to quality is a major step forward for textile manufacturing. The AI provides the data needed for smarter manufacturing and better efficiency.

Integrating with Industry 4.0 Ecosystems

Modern inspection systems do not operate in isolation. They are a key part of the Industry 4.0 ecosystem. The AI in machine vision integrates seamlessly with Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) software.

What does this integration do? When the AI detects a defect, it sends this data instantly to the MES. The MES can then adjust the manufacturing process or alert operators. This creates a closed-loop quality control system.

The Industrial Internet of Things (IIoT) connects all machinery. Communication protocols like OPC UA and MQTT allow the inspection system to "talk" to other equipment. This flow of data ensures that insights from defect detection inform the entire manufacturing operation. This connectivity turns a factory into a smart, responsive, and optimized system for producing high-quality textiles. The AI uses images and data to drive this transformation in textile manufacturing.

The future of textile inspection is here. A convergence of advanced AI, sophisticated imaging, and connected systems creates a new quality control paradigm. This automation transforms the process. The industry moves from reactive defect detection to a proactive system. This AI uses data for predictive defect insights. The AI provides superior precision. This AI-driven quality control revolutionizes the entire textile manufacturing value chain. The AI enhances efficiency. Better defect detection and data analysis from the AI lead to higher quality textile products. This AI offers unmatched precision and quality. The AI makes the textile industry more sustainable and competitive.

FAQ

How does AI improve fabric inspection?

An ai system offers superior accuracy. The ai learns from image data to find defects. This ai improves its detection skills over time. The ai ensures consistent quality control. The ai is a powerful tool for manufacturing. The ai provides unmatched precision.

Is an AI inspection system expensive?

An ai system has an initial investment. However, the ai reduces material waste significantly. The ai also boosts production efficiency. This ai delivers a strong return on investment. The ai saves manufacturers money in the long run. The ai is a cost-effective solution.

What makes AI different from older automated systems?

Older systems follow fixed rules. An ai system learns and adapts to new defects. The ai uses complex deep learning models. This ai identifies subtle or rare issues. The ai makes intelligent, data-driven decisions. The ai offers a higher level of intelligence.

How difficult is it to integrate AI into a factory?

Modern ai systems integrate easily. The ai connects with existing production machinery. The ai communicates with factory management software (MES/ERP). This ai creates a streamlined workflow. The ai simplifies the entire quality process. The ai is designed for modern factories.

See Also

Forecasting Textile Machine Needs: AI's Role in 2025 Maintenance

Revolutionizing Fashion Supply Chains: AI Sensors' 2025 Impact Explored

Innovative AI Solutions: Sustainable Fashion for a Greener Planet

Optimizing Fashion Returns: Smart AI Solutions for Immediate Efficiency