Yes. Machine learning provides the key to achieving unprecedented color consistency.

AI models analyze vast datasets from the textile dyeing process. This AI guides the dyeing process. AI enhances dyeing. AI perfects dyeing. AI controls dyeing. The AI improves color. The AI perfects color. The AI refines color. The AI controls color. AI is key to dyeing.

This AI capability is the secret. It moves textile dyeing beyond human subjectivity and traditional dyeing limitations.

Solving color consistency with machine learning

Machine learning tackles the challenge of color consistency from three critical angles. It provides predictive intelligence, dynamic process control, and flawless quality assurance. This combination moves textile dyeing from an art form into a precise science.

Predictive color matching

Traditional color matching often involves guesswork. AI models for color prediction eliminate this uncertainty. These systems analyze complex data to forecast the final fabric color with incredible precision. The AI achieves this through several advanced methods.

- Neural networks map the relationship between dye concentrations and the final color.

- Convolutional Neural Networks (CNNs) extract hidden information from images to predict color trends.

- Recurrent Neural Networks (RNNs) use hyperspectral color data for a more precise prediction of dye recipes.

These machine learning models train on vast datasets. A model might learn from 763 fabric samples to achieve near-perfect accuracy. It analyzes features like average RGB values and CIEXYZ color data. This allows the AI to predict the final dry color from a wet sample. A study at the Wilson College of Textiles proved this capability. This prediction power helps manufacturers avoid costly re-dyeing. A random forest model also showed a 12% reduction in color non-conformity, improving dyeing quality. This makes color matching a reliable, data-driven process. The AI ensures the right color is achieved on the first attempt.

Real-time process adjustments

Achieving the perfect color requires more than a good recipe. It demands constant control during the dyeing process. AI systems provide this control through continuous real-time monitoring.

How it Works: High-precision temperature sensors and pH probes are placed directly in the dye bath. These sensors feed live data to the AI. The AI analyzes this information instantly.

If the system detects a deviation, it makes real-time adjustments. The AI can modify dye flow, adjust temperatures, or alter dye concentrations. This active monitoring ensures the dyeing process stays within optimal parameters. AI visualization platforms create a feedback loop for immediate control. This real-time monitoring and control maintains color consistency across different batches. The AI provides alerts for any issues, enabling operators to take immediate action. This level of control is essential for modern textile dyeing. It minimizes waste and guarantees the target color.

Automated quality control

The final step in ensuring perfect color is inspection. Human inspections can be slow and inconsistent. Automated quality control systems powered by AI offer a superior solution. These systems use computer vision for the inspection of finished fabrics.

High-resolution cameras capture images of the fabric as it moves down the production line. The AI then analyzes these images for defects. Deep learning models, especially CNNs, learn to identify complex visual patterns. They can spot a wide range of dyeing defects.

- Color inconsistencies

- Stains and spots

- Fading or uneven dyeing

- Structural anomalies

The AI compares the fabric to a "golden template" or an ideal sample. It can detect subtle color shifts that are invisible to the human eye. This process allows the AI to distinguish true defects from natural fabric variations, reducing false positives. The detection of a defect is instant. The system classifies the defect by type, severity, and location. This detailed feedback helps improve the dyeing process. Companies like EasyODM provide AI-powered solutions that integrate directly into fabric inspection stations.

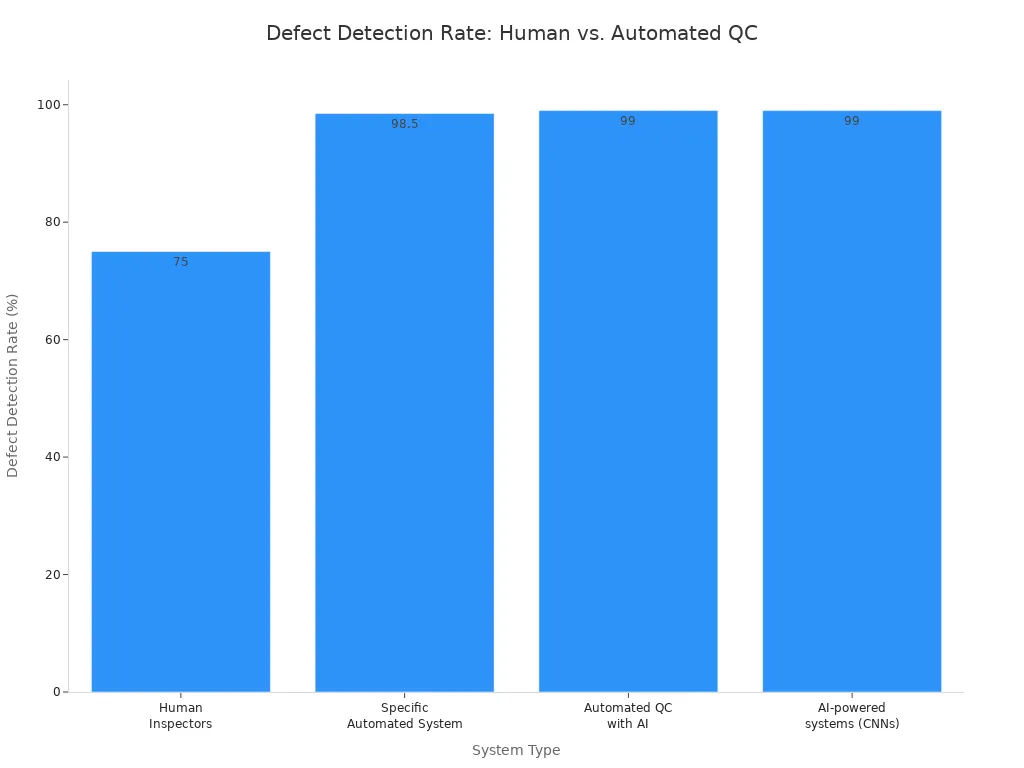

The accuracy of automated quality control is remarkable. AI systems achieve a defect detection rate that far surpasses human capabilities.

With a detection rate exceeding 99%, these systems ensure that only the highest quality fabric reaches the customer. This level of inspection and quality control is critical for brand reputation and customer satisfaction. The AI makes defect detection a fast, accurate, and reliable part of textile dyeing.

Key benefits of ML in dyeing

Integrating machine learning into the dyeing process delivers transformative benefits. It enhances operational efficiency, improves product quality, and promotes environmental sustainability. These advantages give textile manufacturers a powerful competitive edge.

Reduced waste and rework

AI provides a direct path to greener textile dyeing. The technology enables precise resource optimization. AI algorithms analyze historical data to forecast resource needs accurately. This control prevents the overuse of water, energy, and chemicals. The result is a significant reduction in waste and a more sustainable dyeing process.

Traditional dyeing is notoriously resource-intensive. AI-powered dyeing changes this reality. It ensures the correct color is achieved on the first attempt. This first-time-right capability eliminates re-dye cycles. Each re-dye cycle consumes vast amounts of additional water, energy, and harsh chemicals for stripping and reprocessing. AI completely cuts the waste associated with these repeated attempts through precise recipe creation and real-time monitoring.

This resource optimization leads to dramatic savings. A single AI-driven dyeing cycle can achieve what previously took multiple attempts.

| Method | Dyeing Attempts | Total Water Consumption | Water Savings |

|---|---|---|---|

| Traditional Dyeing | 3–4 Cycles | 40,000 Liters | 0% |

| AI-Powered Dyeing | 1 Cycle | 10,000 Liters | 75% |

This efficiency in textile dyeing translates directly to higher profitability. Reduced consumption lowers operational costs. A smaller environmental footprint enhances a brand's image. Companies can market their products as sustainably made. This appeals to environmentally conscious consumers. The AI control over the dye and dyeing process is key to this success.

Unprecedented batch-to-batch consistency

Achieving identical color across different production runs is a major challenge in textile dyeing. AI solves this problem by removing human subjectivity from color assessment. It provides objective, data-driven control for superior batch-to-batch consistency. The AI ensures every yard of fabric meets the exact color specification.

AI models create a digital standard for every color. This standard becomes the single source of truth for quality control. The system uses this data for every aspect of the dyeing operation.

| Aspect | Traditional Method | AI-Driven Approach |

|---|---|---|

| Color Matching | Subjective, relies on skilled labor | Accurate color reproduction, less dependency on skilled labor |

| Color Assessment | Prone to human error | Objective, repeatable results using sensors and AI |

| Color Reproduction | Difficulty in consistency | Real-time dye recipe adjustments for efficient batch-to-batch quality |

| Dye Recipe Development | Trial and error | Predictive dye recipes using vast datasets, reducing waste |

The quality of this consistency is measured using a metric called Delta E (ΔE). A ΔE value below 1.0 is considered an imperceptible color difference. AI systems in dyeing regularly achieve this level of precision. A neural network can predict the final dry color from a wet sample with a median error as low as 0.7 ΔE. This predictive quality control ensures the final product is perfect before the dyeing process even finishes. This level of control makes perfect color a repeatable reality.

Faster time-to-market

Speed is a critical competitive advantage in the fashion and textile industries. AI accelerates the entire production timeline from concept to finished product. It reduces the time spent on color development and quality assurance. This allows brands to respond to market trends faster than ever before.

The primary time savings come from eliminating rework.

- Predictive recipes get the dye formula right on the first try.

- Real-time control prevents errors during the dyeing run.

- Automated quality checks are faster and more reliable than manual inspection.

Companies like Datacolor and Coloro already use AI to streamline their operations. Their AI-based solutions analyze vast color datasets to accelerate dye matching. This technology minimizes the need for manual lab dips and sample approvals. The entire color development cycle shrinks from weeks to days. This speed allows manufacturers to deliver products faster, capture sales, and improve their market position. The AI makes the entire dyeing workflow more agile and responsive.

Implementing ML for color control

Implementing a machine learning system for color control requires careful planning. Success depends on gathering the right data, selecting the correct hardware, and choosing an effective AI model. This process transforms traditional textile dyeing into a data-driven operation.

Essential data and hardware

A successful AI system starts with high-quality data and precise hardware. The AI needs specific information to learn and make accurate predictions for the dyeing process. Key data points include color space information and extracted features.

- Color Spaces: The AI uses systems like RGB, HSV, and Lab to understand color numerically. The Lab color space is especially useful because it aligns with human vision.

- Feature Extraction: The AI analyzes color histograms and color moments to interpret image data. These features help the AI understand color distribution and texture for better color matching.

This data comes from specialized hardware. Spectrophotometers, such as the Spectro 1000 or the portable Spectro P200, measure color values with high precision. Sensors provide real-time monitoring of the dyeing environment. This hardware provides the essential inputs for AI quality control and color matching. The AI uses this information for effective monitoring and control of the textile dyeing operation.

Choosing the right ML model

Selecting the right AI model is critical for achieving accurate color matching and quality control. Different models offer different strengths. The choice depends on the specific needs of the textile dyeing facility. A company must consider its data size, required accuracy, and available resources.

Some models perform better than others for color prediction in dyeing.

| Model Type | Effectiveness for Color Prediction |

|---|---|

| Random Forest Regression | High (Low error, handles non-linearity) |

| Bagging with Decision Tree | High (Similar performance to Random Forest) |

| Deep Neural Network | Lower (Can overfit with limited data) |

| Multiple Linear Regression | Low (Struggles with complex relationships) |

Random Forest models often provide the best results for color matching. They handle the complex, non-linear relationships in the dyeing process well. This leads to better quality and control. Consulting with AI development experts helps a manufacturer select the best algorithm for their specific dyeing needs.

Integrating into your workflow

Integrating AI into an existing textile dyeing workflow presents challenges. Many facilities use legacy systems that lack digital infrastructure. This makes real-time data collection for monitoring difficult. The quality and availability of data are also common hurdles. An AI needs large, well-labeled datasets for effective training.

Overcoming these challenges is key to a successful implementation. A major step is upgrading to automated dyeing machinery that supports digital monitoring and control.

Factories must establish standardized protocols for data collection. This ensures consistency across different batches and materials. The high cost of computational resources is another factor. However, the long-term benefits of improved quality, reduced waste in dyeing, and faster color matching justify the investment. Proper integration turns AI from a concept into a practical tool for perfect color control.

Machine learning is the proven solution for perfect fabric color. The technology delivers precision, reduces waste, and accelerates production. AI achieves consistent color in dyeing. AI optimizes the dyeing process. AI improves dyeing quality. AI controls color. AI perfects dyeing.

Adopting AI is a strategic imperative for the textile industry. AI drives the future of dyeing. AI enables production optimization for dyeing. AI ensures sustainable dyeing and perfect color. This AI integration is essential for competitive and efficient dyeing operations. The AI makes perfect dyeing a reality.

FAQ

How does AI improve dyeing quality?

An AI system enhances dyeing quality. The AI analyzes data from the entire dyeing process. This AI control ensures a better final color. The AI perfects dyeing quality. The AI makes the dyeing process more reliable, improving overall quality.

Can AI work with any fabric for color dyeing?

Yes, an AI model can adapt to different fabrics. The AI learns the unique properties of materials like cotton or polyester. This AI capability allows for precise color application during the dyeing process, ensuring high quality for any fabric type.

Is AI expensive for a dyeing facility?

Initial setup costs for AI can be high. However, the AI delivers long-term savings. The AI reduces waste in the dyeing process. It improves efficiency and dyeing quality. This AI investment leads to greater profitability over time.

What is the main role of AI in color control?

The main role of an AI is achieving perfect color consistency. The AI predicts the final color. The AI also makes real-time adjustments during dyeing. This AI control over the dyeing process guarantees the target color and exceptional quality.

See Also

Machine Learning: Forecasting Fashion Trends to Significantly Boost Retail Sales

AI-Powered Predictive Maintenance Revolutionizing the Textile Industry by 2025

Innovative AI Fashion Solutions: Paving the Way for a Sustainable Planet

Achieving Equilibrium: Predictive Analytics Optimizes Fashion Supply and Demand

Delight Customers: Smart Machine Learning Enhances Personalized Order Experiences