Predictive modeling provides a clear path for the apparel industry's decarbonization. It directly reduces the logistics carbon footprint. Predictive analytics optimizes delivery routes and forecasts demand, cutting wasteful production. These data-driven strategies combat the significant environmental impact of logistics, where shipping and returns generate 37% of retail greenhouse gas emissions. With e-commerce returns near 25%, predictive analytics offers tangible actions. Companies can implement these for retail sustainability, meeting 2025 emission-reduction goals and lessening their carbon impact on the environment. These efforts reduce the overall carbon footprint and emissions.

Core predictive modeling strategies

Core predictive strategies give apparel companies a clear roadmap for 2025. These methods turn data into direct actions. They build agile supply chains that reduce emissions and prepare businesses for disruptions.

Demand forecasting

Accurate demand forecasting is the first step to reduce waste. Overproduction creates massive inventory waste and contributes to water waste during manufacturing. Predictive analytics helps companies align production with what customers actually want. Brands like H&M Group and Zara use AI to forecast demand precisely. This practice cuts down on unsold products and textile waste.

Models use specific data to make these predictions. Key inputs include:

- Product Attributes: Category, color, material, and price.

- Historical Analogs: Performance data from similar past products.

- Pre-launch Indicators: Wishlist additions and social media engagement.

- External Intelligence: Google Trends data and competitor analysis.

Two powerful time-series models for this task are ARIMA and Prophet. Each serves a different purpose in fashion logistics.

| Feature/Model | ARIMA | Prophet |

|---|---|---|

| Best Suited For | Core products with stable demand and consistent seasonal patterns. | Items with weekly fluctuations, promotions, and holiday sales spikes. |

| Advantages | Provides good short-term forecasts and works well with less data. | Handles missing data, includes holiday effects, and is easy to fine-tune. |

| Limitations | Assumes linear relationships and is less responsive to sudden changes. | May underperform with highly irregular shifts without external data. |

A study on footwear sales found Prophet achieved 98.8% accuracy for annual predictions. SARIMA, a variant of ARIMA, was 15 times faster and better for monthly forecasts. Choosing the right model helps create a powerful forecasting engine. This engine not only prevents overproduction but also improves reverse logistics. By predicting return rates, companies can better manage staff and warehouse space, making the entire process more efficient.

Route and load optimization

Transportation is a major source of carbon emissions in the apparel industry. Route and load optimization directly tackles this challenge. These models solve the complex Vehicle Routing Problem (VRP). The goal is to find the most efficient routes for delivery fleets. A specialized version, the Green Vehicle Routing Problem (GVRP), specifically aims to minimize fuel consumption and its resulting emissions.

Route optimization software, including VRP solvers, can reduce fuel costs by 15-30% annually. This delivers a significant impact on a company's carbon footprint.

Effective route planning considers traffic, delivery windows, vehicle capacity, and fuel usage. By optimizing loads, companies ensure no truck travels half-empty. This dual focus on routes and loads reduces the total miles driven and the fuel burned per package. It is a critical lever for shrinking the carbon impact of logistics.

Optimized inventory placement

Where a company stores its inventory has a huge impact on delivery emissions. Centralized warehouses often lead to long shipping distances. Optimized inventory placement uses predictive modeling to strategically position products closer to customers. This strategy relies on models like the guaranteed-service model (GSM) to determine ideal stock levels in different locations.

This approach shortens last-mile delivery distances. Shorter routes mean less fuel consumption and lower carbon emissions. For example, reallocating inventory to urban micro-fulfillment centers allows for local fulfillment. This avoids long-haul transportation from a distant warehouse. Apparel brand Burberry uses AI to monitor stock levels and optimize its inventory, which supports its sustainability goals and reduces waste. Smart placement is essential for efficient and clean logistics.

A foundation for sustainability

These predictive strategies do more than offer short-term wins. They build a foundation for long-term sustainability and resilience. By 2025, companies can use these models to create agile supply chains. Such supply chains are better equipped to handle disruptions through:

- Data Analytics: Gaining clear insights for better demand forecasting.

- Supplier Diversification: Using data to identify and manage local suppliers.

- Process Automation: Automating order processing for faster response times.

Predictive analytics also enables circular business practices. By forecasting return volumes, companies can streamline reverse logistics. This makes it easier to repair, resell, or recycle garments. Furthermore, predictive modeling is crucial for broader goals. It helps businesses align with Environmental, Social, and Governance (ESG) metrics. As technology advances, these tools will help optimize energy use and manage resources across the entire supply chain. Adopting these models now is a direct investment in a cleaner environment and a more sustainable future. 🌎

Implementation: Data and technology

Effective predictive modeling requires a strong foundation of data and technology. Companies must gather the right information and use the right tools to turn insights into action. This implementation phase is critical for transforming apparel logistics and achieving sustainability goals.

Essential data inputs

High-quality data is the fuel for any predictive analytics engine. To build a complete picture, these models draw from several key sources. Each dataset provides a different piece of the puzzle for forecasting demand and optimizing logistics.

- Sales and Customer Data: This includes historical sales records, customer orders, and current inventory levels. It also covers customer demographics, online shopping habits, and past purchase patterns.

- Market and External Data: Models incorporate broader market trends, competitor performance, and pricing data. External factors like social media trends, online searches, and even weather forecasts help refine predictions.

- Operational Data: Real-time information is essential for dynamic adjustments. This includes point-of-sale data, warehouse stock levels, supplier delivery schedules, and customer return rates.

For route optimization, real-time transportation data is especially important. Vehicle telematics provides live information about a fleet's location, speed, and fuel consumption. This data allows logistics platforms to make instant, intelligent decisions that reduce fuel use and carbon emissions.

Gathering this data presents significant hurdles. Companies often face challenges that can slow down or derail their predictive analytics initiatives. Common obstacles include:

- Data Silos: Functional teams often hoard data, and managers may resist sharing it. Legacy IT systems can make this problem worse.

- Data Quality: Records may be inaccurate, incomplete, or inconsistent across different systems.

- System Integration: Combining data from multiple, separate sources is a major technical challenge.

- Cultural Resistance: Teams may prefer relying on intuition over data-driven insights, creating resistance to change.

The 2025 technology stack

A modern technology stack gives companies the power to collect, process, and analyze data at scale. For apparel brands aiming to reduce their carbon footprint by 2025, the right stack is not optional—it is essential. It typically includes cloud platforms, analytics software, and specialized Supply Chain Management (SCM) systems.

Cloud platforms like Amazon Web Services (AWS) and Microsoft Azure provide the scalable infrastructure needed for heavy data processing. They offer a suite of tools for every stage of the data lifecycle, from storage to machine learning. For example, a UK food service specialist uses Azure to power its BI environment, while an American manufacturer uses AWS for real-time data management. These platforms are the backbone of modern predictive analytics for cleaner logistics.

| Feature | AWS | Azure |

|---|---|---|

| Data Storage | S3, DynamoDB, Redshift | Blob Storage, Cosmos DB, Synapse Analytics |

| Analytics & ML | SageMaker, QuickSight | Azure ML, Power BI, Synapse Analytics |

| Specific SCM Tools | AWS Supply Chain, Amazon Forecast | Dynamics 365 SCM, Azure Digital Twins |

Analytics software like Python and R, along with their extensive libraries, allows data scientists to build and train custom models. These tools are used to create the algorithms that forecast demand and optimize delivery routes.

Finally, modern SCM systems with integrated AI tie everything together. These platforms use AI to deliver powerful benefits that directly impact emissions.

- Enhanced Visibility: AI tracks supplies in real-time across complex logistics networks.

- Warehouse Efficiency: It optimizes warehouse layouts and plans efficient routes for workers and robots.

- Reduced Operating Costs: AI automates repetitive tasks and predicts equipment maintenance needs to minimize downtime.

- Accurate Inventory: AI-enabled systems provide precise control over inventory, reducing waste and unnecessary transportation.

Measuring your carbon footprint

To reduce a carbon footprint, a company must first measure it. Tracking performance provides the data needed to verify that predictive models are working. Companies can use established frameworks like the GLEC Framework and ISO 14083 to accurately report their carbon emissions. This creates a clear baseline for improvement.

Key performance indicators

Key performance indicators (KPIs) help companies track progress toward sustainability goals. For apparel logistics, the most important KPIs focus on efficiency and emissions. A recent survey showed that 69% of shippers track fuel efficiency, while 60% monitor CO2 emissions. These metrics fall into three categories:

- Scope 1: Direct carbon emissions from company-owned vehicles.

- Scope 2: Indirect emissions from purchased electricity.

- Scope 3: All other indirect emissions from the supply chain, including third-party transportation.

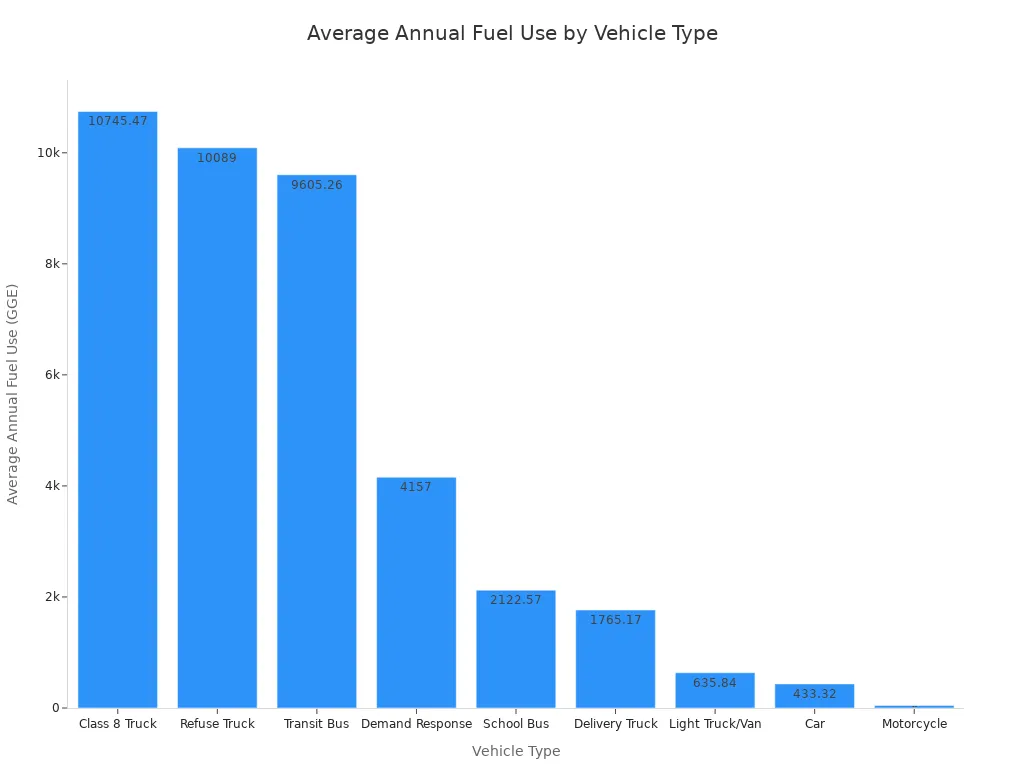

Fuel consumption metrics

Fuel consumption is a direct measure of a company's logistics footprint. The basic formula is simple: CO2 emissions = Fuel consumption × Emission factor. Different vehicles consume different amounts of fuel. Delivery trucks use far more fuel than smaller vans or cars, creating a larger impact.

By tracking fuel use per vehicle, companies can calculate their total carbon output. Predictive models help reduce this number by finding more efficient routes and improving load management.

Return rate reduction

Online apparel returns have a massive environmental impact. Return rates can reach as high as 50%, generating up to 24 million metric tonnes of CO2 annually. Each return creates more packaging waste and requires extra transportation. This process also leads to significant water waste when items are remanufactured or disposed of. Reducing returns is one of the most effective ways to lower a company's carbon footprint.

Last-mile distance

The final leg of a delivery journey, the last mile, accounts for up to 50% of total delivery emissions.

Predictive models that optimize inventory placement can cut last-mile distance by 40–60%.

By placing products in micro-fulfillment centers closer to customers, companies shorten this final, carbon-intensive step. Shorter routes mean less fuel burned and a smaller impact on the environment. This makes last-mile optimization a critical strategy for cleaner logistics.

Predictive analytics offers powerful strategies for cleaner apparel logistics. Demand forecasting, route optimization, and smart inventory placement directly reduce a company's carbon footprint. Adopting predictive modeling is a measurable action, not a theory. It cuts carbon emissions and product waste.

Companies must invest now in the data and technology for their logistics. This commitment builds a foundation for sustainability. It ensures a smaller footprint by cutting carbon emissions and waste. Predictive analytics makes cleaner logistics an achievable goal for 2025.

FAQ

How does predictive modeling reduce carbon emissions?

Predictive modeling optimizes delivery routes to burn less fuel. It also forecasts demand, which prevents wasteful overproduction. These actions reduce the total number of shipments and shrink a company's carbon footprint.

What is the most important data for these models?

High-quality data is the fuel for predictive models. The most essential inputs include historical sales records, customer location data, and real-time warehouse inventory levels. Accurate data ensures effective and reliable predictions.

Can small brands use predictive analytics?

Yes. Cloud platforms offer scalable solutions that fit different budgets. A small brand can start with a single model, like demand forecasting, and expand its analytics capabilities over time. This makes the technology accessible to businesses of all sizes. 📈

What is the first step to implement these strategies?

A company's first step is to unify its data. It must break down internal data silos between sales, logistics, and marketing teams. A centralized data source is the essential foundation for any predictive analytics project.

See Also

Forecasting Fashion's Future: Predictive Models Revolutionize Retail by 2025

Harmonizing Hues: Predictive Analytics Optimizes Fashion Supply and Demand

AI's Vision: Predictive Maintenance Transforms Textile Manufacturing by 2025

Smart Shelves: Predictive Analytics Streamlines Retail Re-stocking by 2025

Unveiling Tomorrow's Style: Machine Learning Predicts Trends, Skyrockets Sales