Artificial Intelligence (AI) is revolutionizing the textiles we wear. This AI technology rapidly analyzes massive datasets of material properties, making textile innovation faster.

Think of AI as a digital master weaver. This AI can predict a fabric's feel and performance before a single thread is spun.

This AI optimization allows for new material blends. AI creates textiles precisely tuned for comfort and sustainability. AI is essential for optimizing fiber blends. This advanced AI technology helps create high-performance textiles. The AI drives performance optimization.

AI and performance textiles

Artificial intelligence is creating a new generation of performance textiles. Machine learning models process huge amounts of data on fiber properties. This data includes softness, strength, and moisture-wicking capabilities. The AI then predicts the final fabric's function and feel. This technology allows for the precise engineering of multi-functional textiles. The entire process of optimization is faster and more accurate than ever before.

Optimizing fiber blends for comfort

Achieving optimal performance in athletic wear requires a deep understanding of fabric behavior. AI excels at this task. Machine learning algorithms analyze fabric microstructures and material composition. This analysis helps in optimizing fiber blends for specific activities. For example, an AI can recommend the perfect blend of polyester and elastane for a high-intensity training shirt. The goal is maximum moisture-wicking and stretch.

The AI provides data-backed metrics for key performance indicators.

- It predicts a fabric's moisture vapor transmission rate (MVTR).

- It simulates evaporation to estimate realistic drying times.

- It assesses water repellency and air exchange.

This detailed analysis allows designers to create textiles that maintain a comfortable microclimate for the wearer. The AI-driven optimization ensures the final blends deliver superior performance.

Predicting fabric durability

Durability is a critical aspect of high-quality textiles. AI digitally simulates wear and tear. This process tests for issues like pilling, shape retention, and colorfastness. Machine learning models use extensive datasets to forecast a fabric's long-term performance. To predict colorfastness, the AI analyzes many inputs. These include:

- Colorimetric measurements and spectral data

- Information about dyes, like chemical structure and concentration

- Fabric characteristics, such as fiber type and weave

- Process parameters from past dyeing runs

This digital testing significantly reduces the need for physical prototypes. One eco-focused brand used AI-powered tools to cut its physical prototypes by over 70%. This change led to a major conservation of fabric and resources.

This AI technology makes the development of durable blends more efficient. The optimization of materials through simulation ensures better product longevity.

Simulating real-world feel and function

The "handfeel" of a fabric is a subjective but vital quality. AI is learning to quantify this sensation. It uses data from tactile sensing devices and evaluation systems like the Kawabata Evaluation System (KES). Machine learning models integrate this sensor data with fabric structures. This allows the AI to predict the tactile feel of different blends.

Beyond feel, AI also simulates how a fabric will drape and fit. Companies like Style3D AI and Altair are leaders in this field. Their platforms use deep learning to create photorealistic 3D models. The AI technology works in several steps. First, it estimates a person's 3D body shape and pose. Then, a neural network predicts how a garment's specific blends would look on a virtual avatar. This machine learning process maps the texture and material of the cloth onto the body for a realistic preview. This simulation of performance helps designers visualize the final product without making a physical sample. The AI makes the creation of new textiles and blends much faster. This optimization is key to modern textile innovation.

Driving sustainability and circularity with AI

Artificial intelligence is a powerful force driving sustainability and circularity in the textile industry. AI helps designers make better environmental choices from the start. This technology also makes manufacturing processes cleaner and more efficient. The impact of AI on creating sustainable textiles is growing every day.

Designing for efficient recycling

AI helps create new textiles with their end-of-life in mind. The technology assists designers in developing blends that are easier to separate and recycle. This initial design choice has a huge environmental impact. Beyond design, AI is also transforming how we sort used textiles. When AI works with spectroscopic technologies, it can automatically identify the fiber composition of old clothes. This is critical for effective recycling.

This AI-powered sorting process is fast and accurate.

- AI models analyze spectral data to precisely identify different textiles.

- Advanced models like Convolutional Neural Networks (CNNs) improve the sorting of waste cotton blends and other materials.

- This technology achieves real-time classification with an accuracy rate above 95%.

- AI can even identify the specific fibers in complex cotton blends, making it possible to sort materials that were once too difficult to process.

This optimization ensures that more materials, like cotton, are properly recycled instead of ending up in landfills. This improves the recyclability of all textiles.

Improving resource efficiency

AI significantly reduces waste during textile manufacturing. One major area of improvement is in fabric cutting. AI-powered machines use computer vision and advanced algorithms to plan the most efficient cutting patterns. This optimization directly reduces material waste. For example, one small factory lost around $80,000 annually from inefficient cutting of materials like sustainable cotton. AI systems prevent such losses by ensuring maximum use of every fabric roll.

AI also improves quality control. The WiseEye system, for instance, uses computer vision to find over 40 types of fabric defects on weaving machines. It inspects materials like cotton and cotton blends at high speeds with over 90% accuracy. Catching errors early prevents the waste of water, dyes, and energy on faulty textiles. AI is also making the dyeing process for cotton blends more efficient. It provides accurate color matching, which reduces errors and ensures uniform shades across different batches of sustainable cotton. This leads to a major reduction in the environmental impact of production.

Calculating environmental footprints

Understanding the full environmental impact of a product is complex. AI makes this task much easier. It can predict the environmental footprint of textiles across their entire lifecycle. This includes calculating water usage, carbon emissions, and chemical toxicity for different cotton blends. This data empowers designers to make more sustainable material choices.

The EU-funded DIGITX project is a real-world example of this technology in action. This initiative uses AI to develop circular textiles with a low environmental impact.

The project uses AI to forecast the recyclability of different fiber blends and chemical finishes. This guides designers toward creating better products. The AI allows them to test countless digital prototypes of sustainable cotton textiles virtually. This process reduces the need for physical samples and accelerates textile innovation. By predicting the environmental effects of materials like cotton, AI is helping build a more sustainable future. This is a key part of optimizing fiber blends for a better planet.

Accelerating textile innovation with AI

Artificial intelligence (AI) is dramatically speeding up the entire process of textile innovation. This technology helps researchers with every stage of development. The AI provides powerful tools for research. This AI innovation is changing the industry. The AI makes the research and development of new textiles faster than ever.

Speeding up material discovery

AI frameworks can discover new material combinations in a fraction of the time it takes humans. This AI completes complex research and development tasks quickly. An AI agent named FabAgent shows the power of this technology. This AI performs specific research functions to accelerate material development.

- It extracts information from scientific papers and the internet.

- The AI compiles a structured dataset of fabric materials.

- It uses optimization to explore the best solutions for fabric blends.

This AI-driven research and development enables engineers to explore novel fiber combinations and complex braiding patterns with greater precision. For example, AI platforms helped discover PONB-2Me5Cl, a polymer with record-breaking energy density for aerospace use. This kind of research and development is critical for creating next-generation textiles.

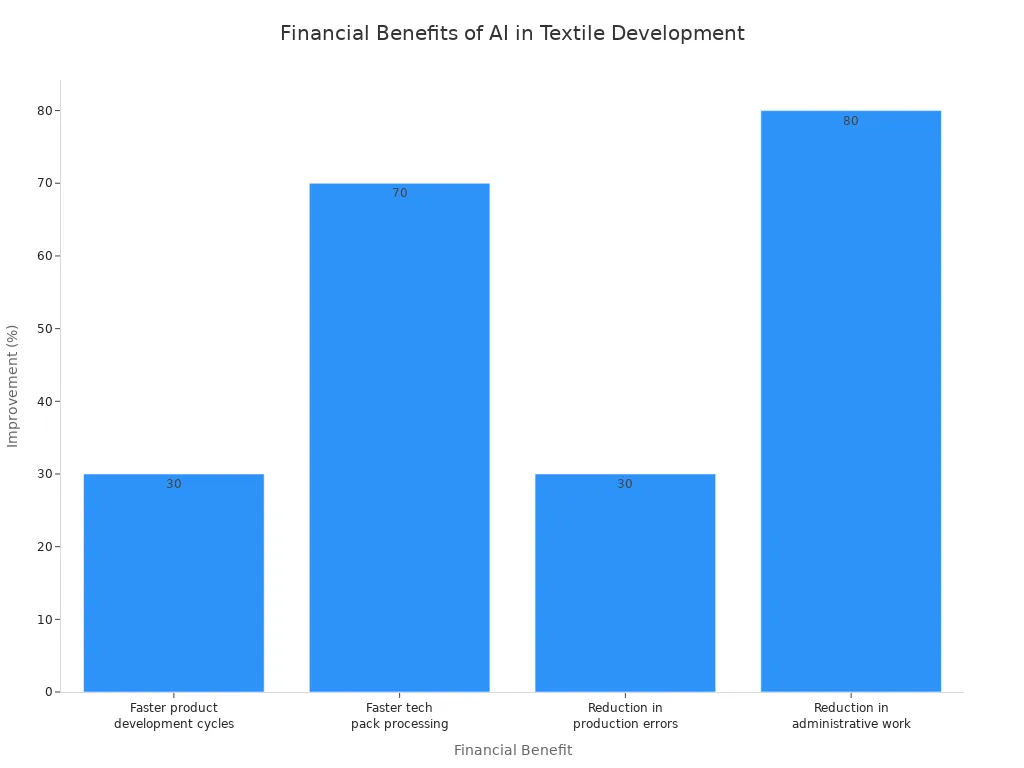

Lowering development costs

Digital prototyping and simulation have a huge financial impact. They drastically reduce the material and financial costs of research and development. This makes textile innovation more accessible for brands of all sizes. AI tools can cut product development cycles by 20–40%. This efficiency comes from reducing errors and administrative work. The AI streamlines the entire development workflow.

By using AI, companies can launch products faster and operate with greater efficiency. This AI-powered research and development minimizes waste and builds stronger buyer trust.

Bringing new fabrics to market

Faster research and lower development costs help bring new fabrics to market quickly. AI allows designers to test countless ideas digitally. This process identifies high-performance blends without making physical samples. The result is a much shorter timeline from concept to consumer. This accelerated path ensures that the latest advancements in performance and sustainability reach the market sooner. Better textiles with superior performance are now a reality thanks to AI.

The predictive power of AI creates high-performance textiles, drives sustainability, and accelerates innovation. This technological impact is not a futuristic concept. It is a present-day reality changing the materials in our lives. The future of AI-driven design promises even greater personalization. The AI will continue to evolve, leading to exciting new developments.

The next wave of AI innovation will bring:

- Smart textiles that adapt to body temperature for enhanced performance.

- Mass personalization, allowing AI to help design custom clothing for everyone.

- AI-powered systems that create entirely new fashion aesthetics.

This advanced AI ensures the next generation of textiles will offer superior performance and personalization. The AI is building a better future for fabric.

FAQ

How does AI predict a fabric's feel?

The ai uses data from special sensors. This ai analyzes fabric structure and material properties. The ai then predicts how the fabric will feel to the touch, a quality known as "handfeel."

Is this AI technology expensive?

The ai makes innovation more accessible. Digital prototyping with ai reduces costs. This allows smaller brands to use advanced ai tools for textile development, saving money on physical samples.

How does AI help the environment?

The ai helps designers create recyclable blends from the start. The ai also makes manufacturing more efficient. This process reduces water, energy, and material waste during production.

See Also

AI Routing Algorithms Significantly Reduce Fashion Delivery Times by 22%

Optimizing Brand Operations Through AI-Powered Capacity Planning Solutions

Intelligent Fashion AI Solutions: Streamlining Product Returns for Efficiency

Revolutionary Fashion AI Solutions: Paving the Way for a Sustainable Planet

Innovative Technologies: Revolutionizing Material Handling Processes for Enhanced Efficiency