The e-commerce logistics market is rapidly expanding, with projections showing growth from USD 315.82 billion to over USD 1.52 trillion by 2030. This growth created an urgent need for the company to control its rising shipping cost. The company implemented ai-driven packaging optimization to solve this challenge.

The AI system analyzes product dimensions, order combinations, and rules from carriers. This AI selects the most cost-effective packaging for every single shipment. The use of AI led to a direct reduction in the overall shipping cost.

The Problem: High Shipping Costs

Before implementing its AI solution, the company faced significant challenges with its manual packaging process. These inefficiencies directly inflated shipping costs and wasted resources. The reliance on human judgment without the support of an AI system created several operational bottlenecks.

Manual Process Pitfalls

The company's manual workflow had several key weaknesses. Warehouse teams often used oversized boxes for smaller items. This practice required excessive void fill material, which increased the material cost for each package. More importantly, it led to higher shipping costs due to dimensional weight (DIM) surcharges.

Carriers like FedEx and UPS calculate shipping charges based on package volume, not just actual weight. Their policy rounds every dimension up to the next whole inch. This change inflates the billable volume, pushing shipments into more expensive billing categories. This policy significantly increased the final shipping cost. Other operational issues included:

- Inefficient Workflows: Outdated systems and unoptimized picking and packing processes created delays.

- Neglecting Quality Control: Rushed quality checks resulted in incorrect or damaged shipments, increasing returns and customer dissatisfaction. This added to the overall operational cost.

Quantifying the Financial Impact

The financial impact of these manual processes was substantial. The company discovered that an estimated 20-30% of its total shipping spend was wasted on unnecessary material and carrier fees. The DIM weight policies were a primary driver of this excess cost. The AI analysis later confirmed how even small dimensional changes triggered significant surcharges.

Note: The company's pre-AI data showed that without an intelligent system, packers could not possibly calculate the optimal box for every order, leading to consistent overspending. The future AI would need to solve this complex calculation to reduce this cost.

The table below shows how seemingly minor packaging errors led to major increases in shipping costs.

| Scenario | Pre-AI Manual Packing Issue | Financial Consequence |

|---|---|---|

| Standard Package | A 5 lb. package's dimensions rounded up, increasing its DIM weight. | The shipment was billed at a higher weight class, increasing the base cost. |

| Medium Package | A slight increase in one dimension pushed the box over a carrier threshold. | An "Additional Handling Charge" (AHC) was added to the shipping cost. |

| Large Package | An oversized box was used, exceeding length and girth limits. | The package incurred a significant "Oversize Surcharge," drastically raising costs. |

This data made it clear that an AI-driven approach was necessary to control these escalating costs and optimize the entire shipping operation. The company needed an AI to make perfect choices every time.

The Solution: AI-driven Packaging Optimization

Facing unsustainable shipping expenses, the company pivoted to a technology-first strategy. The core of this strategy was implementing an ai-driven packaging optimization system. This solution transformed the warehouse from a manual operation into a data-driven hub of efficiency. The new system addressed the root causes of high shipping cost by introducing precision and intelligence into every step of the fulfillment process.

Building a Digital Warehouse Twin

The first step was to create a digital warehouse twin. This is a virtual, real-time replica of the entire physical warehouse. It mirrors every asset, process, and piece of inventory. The company built this digital twin by integrating data from multiple sources.

- Warehouse Management System (WMS): Provided foundational data on inventory, storage locations, and product details.

- Product Information: The system cataloged the exact dimensions, weight, and fragility level for every single item.

- Packaging Materials: It stored data on all available box sizes and filler materials, including their cost and protective qualities.

- IoT Sensors: Real-time data from sensors on equipment tracked operational speeds and equipment conditions.

This digital environment became the AI’s playground. The ai could run countless simulations to test different packing combinations without physically moving a single box. This foundational optimization step was critical for enabling intelligent decision-making and improving overall efficiency.

Note: Creating a successful digital twin depends heavily on data quality. The company invested in ensuring all product and packaging data was accurate and complete, as this information is the bedrock upon which the entire AI system operates.

How the AI Makes Decisions

With the digital twin in place, the ai could begin making perfect shipping decisions. The system uses complex algorithms to solve what is known as the "three-dimensional bin packing problem" for every order. It determines the ideal box by analyzing all items in an order simultaneously.

The ai considers multiple variables to make the best choice:

- Item Dimensions: It calculates the total volume of all products.

- Product Fragility: The system uses ai-powered predictive models to assess risk. For fragile items, the ai recommends stronger materials or specific void fills to ensure a safe delivery.

- Box Selection: Using algorithms like Random Forest, the ai evaluates all available box sizes and selects the smallest one that can safely contain the items. This directly minimizes dimensional weight and eliminates unnecessary void fill, reducing material cost.

This intelligent process removes human guesswork. Packers no longer need to estimate which box to use. The system tells them the exact box for every order, ensuring optimal packing every time. This is how ai-driven solutions make consistently better shipping decisions. Several platforms, such as Packify.AI and Pacdora, offer similar ai-powered optimization features.

Rate Shopping Optimization

The final piece of the puzzle was optimizing the shipping method itself. The company implemented an AI-powered rate shopping tool that integrates directly with carrier APIs. For every packed order, the ai automatically queries multiple carriers to find the best shipping option based on a balance of cost and delivery speed.

The system analyzes a wide range of factors in real-time.

| Data Point | How the AI Uses It |

|---|---|

| Package Specs | Considers final dimensions and weight to get accurate quotes. |

| Destination | Checks carrier zones and service availability for the delivery address. |

| Transit Time | Compares ground, express, and freight options to meet delivery promises. |

| Total Cost | Models the complete shipping cost, including base rates and all potential fees. |

This automated process allows the company to make sophisticated cost vs. speed trade-offs for each delivery. The ai can select a cheaper ground freight option for a non-urgent order or a faster air freight service for a priority shipment. This dynamic approach to shipping method optimization ensures the lowest possible cost for every last-mile delivery. The system provides accurate delivery estimates, improving the customer experience while cutting freight expenses. This level of freight cost prediction and analysis was impossible with the old manual workflow. The ai-driven packaging optimization system now controls the entire journey, from box selection to final carrier choice, guaranteeing the most cost-effective delivery every time.

The Results: Measurable Savings and Efficiency

The shift to an AI-driven system produced immediate and substantial results. The company transformed its fulfillment process from a cost center into a source of operational efficiency and savings. The AI delivered measurable improvements across shipping expenses, material usage, and environmental impact.

Reduced Shipping Expenses

The most direct benefit was a significant cost reduction in shipping. The AI system eliminated guesswork, ensuring every package used the most economical box and carrier service. For example, using a properly fitted box for a single delivery can create over 12% savings by avoiding dimensional weight penalties. This micro-optimization, applied to thousands of shipments, generated massive savings. The company's experience reflects a broader industry trend where businesses using AI for freight management achieve an average transportation cost reduction of 10%.

The AI's ability to perform real-time rate shopping for every last-mile delivery was a game-changer. It consistently identified the best freight option, balancing delivery speed with total cost. The financial outcomes below show the clear impact of this optimization.

| Metric | Before AI Optimization | After AI Optimization |

|---|---|---|

| Annual Shipping Spend | $1.2 million | Reduced by 10-12% |

| Gross Parcel Spend | N/A | Saved 15% |

| Total Savings (36-month term) | N/A | Nearly $500,000 |

This data confirms that the AI-driven packaging optimization strategy directly lowered freight costs and improved the company's bottom line.

Material and Labor Savings

Beyond lower shipping fees, the company achieved major savings in materials and labor. The AI system's precision dramatically reduced the need for cardboard and void fill. Machine-vision-driven systems enabled smarter, real-time decision-making for every package.

- The AI 'right-sizes' cartons for every order.

- It achieves 'precise void fill in every carton.'

- This process minimizes waste and material cost per delivery.

This new process also boosted operational efficiency. With the AI providing clear instructions, packers worked faster and with fewer errors. Early adopters of AI in supply chains report efficiency gains of around 30%. By removing the cognitive load of choosing a box, the AI allowed the warehouse team to increase its throughput significantly. This improvement in packing speed and accuracy translated to lower labor costs per package and faster order fulfillment.

Boosting Sustainability Efforts ♻️

The financial benefits of the new system came with powerful environmental advantages. By optimizing packaging, the company directly reduced its carbon footprint.

“When you dig into it, packaging is the biggest user of plastic, and plastic comes from fossil fuels, which are a major cause of climate change.” — Anna-Liisa Palatu, CEO and co-founder of Woola

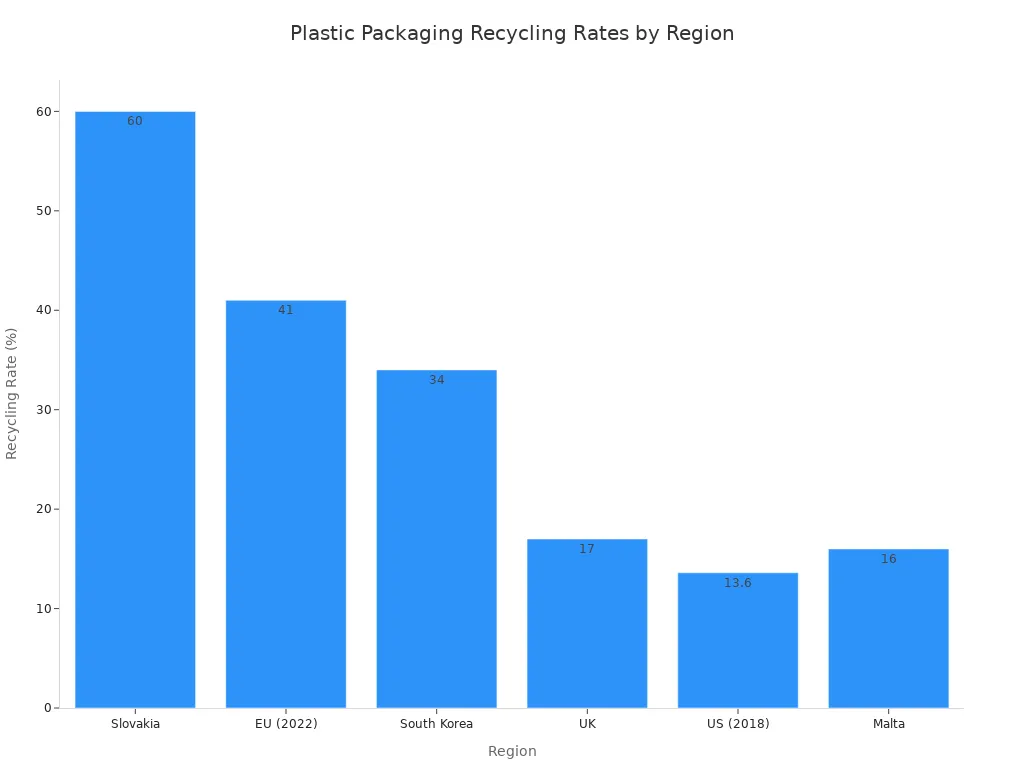

Globally, 91% of all plastic is discarded, and materials like plastic can take up to 1,000 years to decompose in landfills. The company's AI-driven approach tackles this problem head-on by using less material for every delivery. This reduction in waste is critical, as recycling rates vary widely and are often insufficient.

Smaller, lighter packages also mean less fuel is consumed during freight transit, further lowering emissions for each last-mile delivery. The company now follows a clear framework to measure and minimize its environmental impact:

- Material Selection: Choose materials with a smaller carbon footprint.

- Design Optimization: Use less packaging and eliminate unnecessary items.

- Transportation Optimization: Consolidate shipments and use lighter packaging.

- End-of-Life Management: Promote recycling and use of certified materials.

This AI-powered strategy proves that what is good for the bottom line can also be good for the planet. The company cut costs while building a more sustainable and responsible shipping operation.

The company's journey confirms that ai-driven packaging optimization is a powerful tool. It directly cuts shipping cost by choosing the most efficient package every time. The company followed a three-step path: assessing the problem, implementing the ai solution, and measuring the successful results. This ai-driven optimization proves that packaging is not a fixed cost.

It is a prime opportunity for significant savings and cost reduction.

FAQ

What is the primary benefit of AI packaging optimization?

The system directly reduces shipping costs. It selects the most cost-effective box and carrier for every order. This optimization ensures a more efficient and economical delivery process from start to finish.

How does the AI handle fragile items?

The AI uses predictive models to assess risk. For fragile products, it recommends stronger boxes or specific void fill materials. This process ensures a safe and secure delivery without damage.

Does the AI also choose the shipping carrier?

Yes. The system performs real-time rate shopping. It compares multiple carriers to find the best balance of cost and speed for each delivery, optimizing the final shipping expense.

How does this system improve the customer experience?

The AI provides more accurate delivery estimates. Better packaging also reduces the chance of items arriving damaged. This reliability improves the overall customer experience with every successful delivery.

See Also

Leveraging AI for Adaptive Pricing: A Smart Business Strategy

Poly Bagging Advantages: Essential for E-commerce Packaging and Fulfillment

Optimizing E-commerce Warehousing: Smart Strategies for Peak Operational Efficiency

Revolutionizing Fashion Logistics: AI Routing Slashes Delivery Times by 22%

Enhancing Supply Chain Sustainability: Three Lean Logistics Approaches for Impact