Manual quality control presents a persistent challenge in manufacturing. Human inspectors can miss 20-30% of defects, leading to significant costs. An AI-powered system on the factory floor automates defect detection with superior accuracy. This enhances production quality. This article provides a practical roadmap for implementing real-time neural network-based defect classification. It helps manufacturers eliminate every defect from their production process.

Cost Category Annual Cost (Manual QC) Potential Reduction (Digital QC) Total Inefficient QC $40,000 – $75,000 N/A Rework Costs N/A $15,000 – $40,000 Inspection Time N/A 20-30%

Understanding real-time defect classification

Modern quality control moves beyond simply finding a flaw. It requires understanding the nature of each defect. This evolution is the core difference between basic defect detection and advanced defect classification.

From defect detection to classification

Traditional defect detection systems identify anomalies on a production line. However, they do not explain what the defect is. An advanced system using automated defect classification provides more actionable insights. It categorizes each defect by type, size, and location. This allows manufacturers to pinpoint the root cause of a problem, not just its symptom.

AI-powered systems consolidate defect detection and classification into a single, real-time process. This visual inspection technology offers superior performance over older methods.

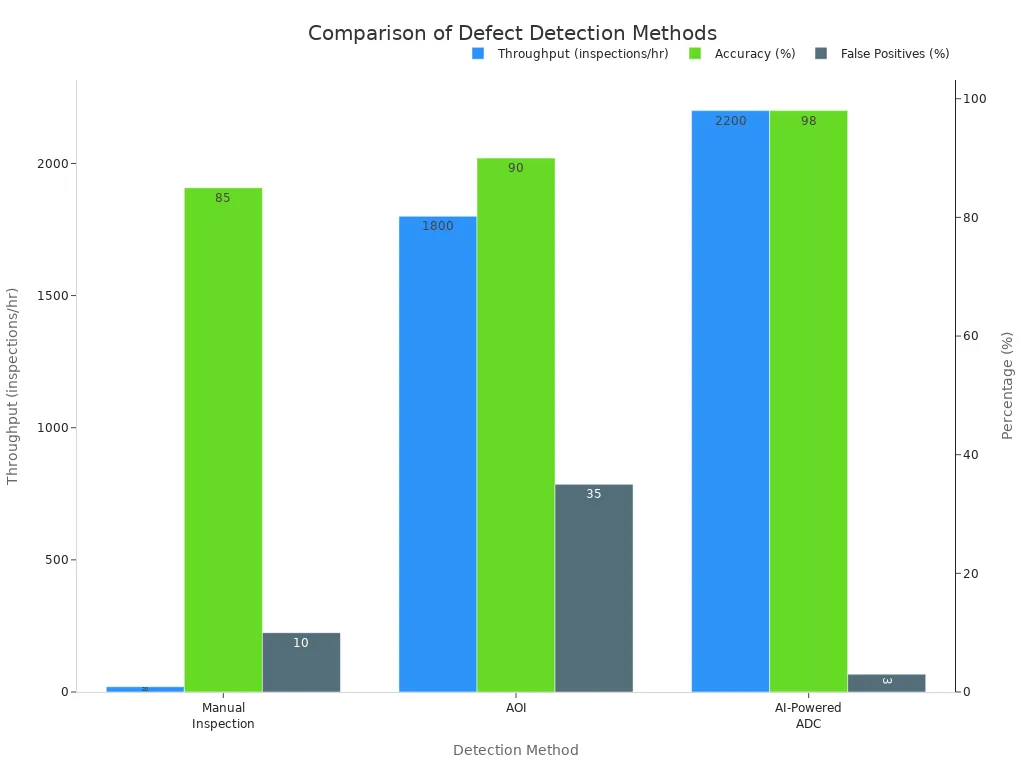

| Metric | Manual Inspection | AOI | AI-Powered ADC |

|---|---|---|---|

| Throughput (inspections/hr) | ~20 | ~1,800 | 2,200+ |

| Accuracy | 85% | 90% | 98% |

| False Positives | 10% | 35% | 3% |

The business case for automated quality control

Automated quality control systems create a strong financial advantage. They significantly reduce operational costs by improving defect detection. Early identification of a defect prevents waste of materials, time, and money. This data-driven automation also reduces the need for large manual inspection teams. By ensuring only high-quality products leave the factory, companies boost revenue and strengthen their market position. The investment in automated defect classification pays for itself through lower costs and higher output.

Core benefits: Better quality, less waste, higher speed

The advantages of automated systems are clear and measurable.

- Better Quality: AI systems can inspect 100% of products, a massive improvement over the 10% typically covered by manual checks. This comprehensive defect detection ensures no defect goes unnoticed.

- Less Waste: Catching a defect early in the production process minimizes rework and scrap. This efficiency directly lowers manufacturing losses.

- Higher Speed: Automated inspection operates in real-time. It keeps pace with high-speed production lines where manual inspection is impossible.

Your 5-step implementation roadmap

Implementing an AI-powered system for defect detection is a structured process. This five-step roadmap provides a clear path for managers and engineers to transition from concept to a fully operational system on the factory floor. Following these steps ensures a successful deployment that delivers measurable results.

Step 1: Collecting quality image data

The foundation of any successful AI model is high-quality data. A robust dataset is essential for training a system that can accurately identify every type of defect. The model's performance directly reflects the quality of the images it learns from.

Key practices for data collection include:

- Prioritize High-Quality Images: The process must start with clear, high-resolution images. Poor-quality data will limit the effectiveness of even the most advanced AI models.

- Ensure Dataset Diversity: The image collection should capture real-world production variations. This includes different lighting conditions, camera angles, and product positions. This diversity helps the model generalize well and avoid errors.

- Balance Quantity and Quality: A large dataset is beneficial. However, a smaller, high-quality dataset is more valuable than a large, poor-quality one. Teams should also include images of non-defective products to help the model learn what a "good" product looks like and reduce false positives.

- Use Data Augmentation: When collecting a large number of images for a specific defect is difficult, data augmentation can help. This technique artificially expands the dataset by creating modified copies of existing images, improving model robustness.

Step 2: Annotating data to train the AI

After collecting images, the next step is annotation. This process involves labeling each image to teach the AI what to look for. Accurate annotation is critical for effective defect detection. It tells the model the exact location, size, and type of each defect.

Tip: Avoiding Common Annotation Errors 📝

Inconsistent or inaccurate labels can confuse the model. To prevent this, teams should establish clear guidelines and review processes. Common pitfalls to avoid include:

- Misinterpreting Instructions: Annotators may label multiple objects instead of one. Clear instructions prevent this.

- Occlusion Errors: Annotators might incorrectly label partially hidden objects. Guidelines should specify how to handle these cases.

- Missing Labels: Rushing can cause annotators to miss a defect. A multi-step review process helps catch these omissions.

- Inconsistent Labeling: Different team members may annotate the same defect type differently. Regular training and clear standards ensure consistency.

Step 3: Training your neural network model

With a well-annotated dataset, the team can begin training the neural network. This phase transforms the labeled images into an intelligent model capable of automated defect detection. The process is iterative and requires careful configuration.

The typical training workflow involves several key stages:

- Data Preparation: All images are resized to a uniform dimension (e.g., 224x224 pixels). The dataset is then shuffled and split into three parts: a training set (for learning), a validation set (for tuning), and a testing set (for final evaluation).

- Model Architecture: The team defines the structure of the neural network. This includes selecting the number of layers, choosing activation functions like 'ReLU', and designing the overall model framework.

- Optimizer and Loss Function: An optimizer (like 'Adam') and a loss function (like 'BinaryCrossEntropy') are chosen. These components help the model learn efficiently and measure its errors during training.

- Model Training: The model trains on the dataset for a set number of cycles, or "epochs." During this phase, it learns to associate specific visual patterns with different defect types.

- Model Evaluation: The model's performance is tested against the validation and testing sets. This step confirms the model can accurately identify a defect in new, unseen images and is ready for deployment.

Step 4: Deploying for real-time defect detection

Deployment moves the trained model from a development environment to the factory floor. The goal is to integrate the model into the production line for real-time analysis without causing disruptions. A phased approach is often the most effective strategy.

Best Practice: Pilot Projects for Smooth Integration

Companies should start with a pilot project on a single production line. This approach allows the team to demonstrate a return on investment on a smaller scale. A successful pilot builds confidence and justifies a broader rollout. Using modular AI systems with open APIs helps layer the new technology onto existing infrastructure, minimizing operational downtime.

Architectural planning is crucial for a successful deployment. The system must be designed for continuous operation and maintenance. This includes containerizing the model for scalability and establishing a robust CI/CD pipeline for automatic updates. This planning ensures the real-time defect detection system remains effective over the long term.

Step 5: Monitoring and improving model accuracy

Once deployed, the model requires continuous monitoring to ensure its accuracy remains high. The production environment can change over time, and the model must adapt. This final step creates a feedback loop for ongoing improvement in defect classification.

Effective monitoring relies on tracking key performance metrics. These may include:

- F1-Score: A balanced measure of a model's precision and recall, especially useful for imbalanced datasets where one defect type is rare.

- Matthew’s Correlation Coefficient (MCC): A robust metric for classification that performs well even when defect classes are of very different sizes.

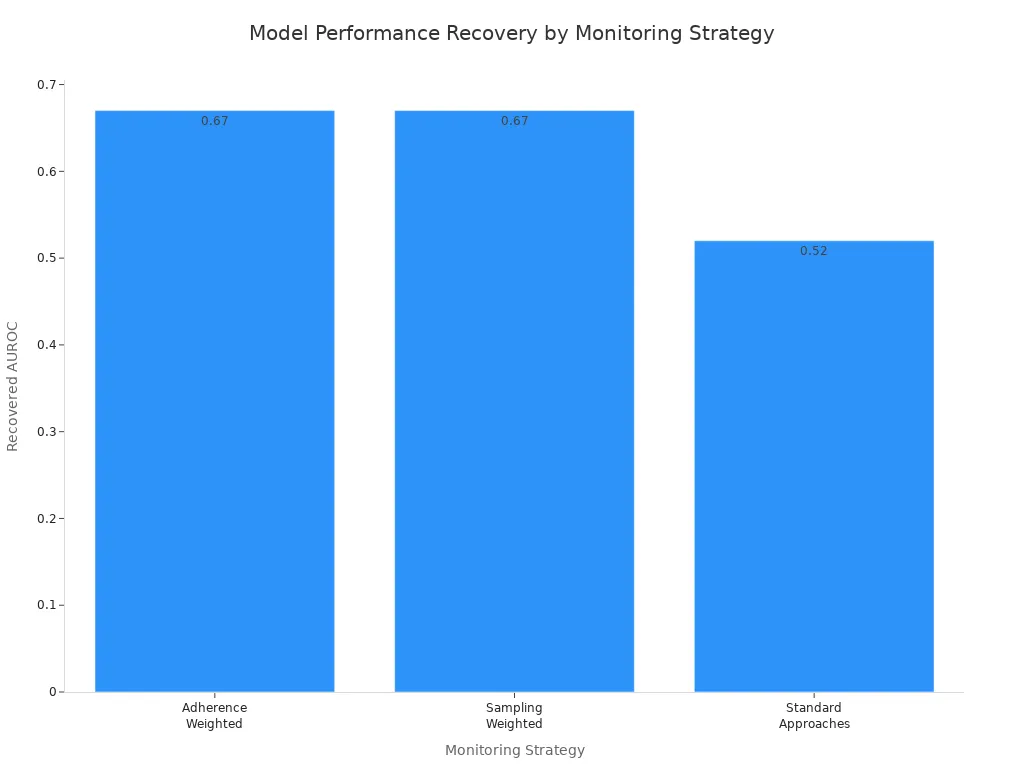

Standard monitoring can be misleading. Advanced strategies provide a more accurate assessment of model performance.

| Monitoring Strategy | Performance Fidelity | Performance Recovery (with data drift) |

|---|---|---|

| Adherence Weighted | Highest fidelity to ground truth | Recovers AUROC to 0.67 |

| Sampling Weighted | Highest fidelity to ground truth | Recovers AUROC to 0.67 |

| Standard Approaches | Most inaccurate estimations | AUROC drops to 0.52 |

A human-in-the-loop feedback system is essential for continuous improvement. This system allows human experts to review and correct the model's predictions. This new, validated data is then used to retrain the model, ensuring it adapts to new defect variations and maintains peak performance. This iterative process makes the AI a self-improving asset for quality control.

Key technologies for AI-driven defect detection

A successful AI-driven defect detection system depends on the right combination of hardware and software. These technologies work together to capture, analyze, and classify flaws on the production line. Choosing the correct components is the first step toward building a reliable solution.

Hardware: Cameras, lighting, and edge devices

High-quality images are the foundation of accurate defect detection. The hardware setup must capture clear, consistent pictures of every product.

- Cameras: Industrial cameras need specific features. Monochrome sensors provide superior contrast to spot a subtle defect. A global shutter is essential for capturing sharp images of fast-moving parts.

- Lighting: Proper lighting is just as important as the camera. Teams use tools like high-output LED panels and polarizing filters to reduce glare and shadows. The camera and lights must be synchronized to ensure every image is perfectly lit, which is critical for consistent defect detection.

Software: Frameworks like TensorFlow and PyTorch

Software turns image data into actionable insights through deep learning. Engineers use powerful frameworks to build and train the models that find each defect. TensorFlow is a popular choice for large-scale production, offering robust tools for deploying models on servers or edge devices.

These frameworks build powerful computer vision models.

- Convolutional Neural Networks (CNNs) are the core of the deep learning analysis, learning to recognize visual patterns associated with a defect.

- Object detection algorithms like YOLO and Faster R-CNN pinpoint the exact location of a defect. YOLO is known for its speed, making it ideal for real-time defect detection, while Faster R-CNN offers high precision.

Overcoming common challenges in production

Manufacturing environments present unique challenges. A successful system must adapt to changing conditions on the factory floor. For instance, teams can solve issues with inconsistent lighting by adjusting light angles. AI can also verify correct product orientation in milliseconds.

A major challenge is finding a new or rare defect. Modern systems use advanced techniques to overcome this.

Solution: Synthetic Data 🤖

When a new defect appears, waiting for enough real examples is not practical. Instead, teams can use Generative AI to create thousands of photorealistic, labeled images of the new defect. This synthetic data trains the deep learning model quickly, ensuring the system can identify the new flaw without disrupting production.

Automated defect classification in action

Theory is valuable, but seeing automated defect classification in a real-world context demonstrates its true power. Many manufacturers face similar challenges that this technology can solve. This case study shows how a company can move from a production bottleneck to a streamlined, efficient operation.

The problem: A manufacturer's inspection bottleneck

A leading manufacturer faced a significant inspection bottleneck. Its manual quality control team could not keep pace with the high-speed production line. Companies like Samsung inspect tens of thousands of components daily, a scale where human error is inevitable. Similarly, automakers like BMW need to identify minute flaws in materials. This manufacturer's process resulted in missed defects, causing costly rework and customer complaints. The slow pace of manual defect detection created a major obstacle to increasing production output.

The solution: A custom CNN-based system

The company implemented a custom system for automated defect classification. Engineers did not use an off-the-shelf solution. They developed a tailored model to handle their unique challenges. The solution involved several key customizations:

- Adapting to specific workflows: The system integrated directly into the existing production line.

- Utilizing transfer learning: The team used a pre-trained model and fine-tuned it on their specific defect types.

- Employing data augmentation: This technique expanded the dataset for rare defect examples.

This approach to automated defect classification allowed the system to accurately identify every type of defect. The custom model provided a robust solution for their defect detection needs.

The results: Measurable gains in accuracy and throughput

The results of the automated defect classification system were immediate and significant. The new process for defect detection dramatically improved quality and speed. The manufacturer saw measurable gains across key performance indicators, reflecting trends seen across various industries.

| Industry / Use Case | Inspection Accuracy Improvement | Throughput Improvement |

|---|---|---|

| Automotive Components | 37% defect reduction | 22% OEE boost, 28% downtime cut |

| Steel Production | Accuracy improved from ~70% to 98% | Annual savings of $2M |

| Pharma (Vial Inspection) | Defect detection accuracy above 97% | Inspection cycles cut by 30% |

By automating its quality control, the company eliminated its production bottleneck. It achieved higher accuracy, reduced waste, and increased overall throughput.

AI-driven defect classification is a transformative technology for flawless production. Companies achieve a stronger competitive edge by improving their production. This technology boosts efficiency and lowers costs across the entire production process. It helps find every defect. Fairlife enhanced its dairy packaging production with AI, achieving 100% traceability for better root cause analysis.

Your Next Step 🚀

Manufacturers can begin their journey by identifying a single production line. A pilot project focused on one defect type can prove the value of automating your production.

FAQ

What is the difference between defect detection and classification?

Defect detection simply finds a flaw. Defect classification identifies the flaw's specific type, size, and location. This provides deeper insight for root cause analysis, turning raw data into actionable information for the production team.

How long does it take to implement an AI system?

A pilot project often takes 3 to 6 months. The timeline depends on data availability and system complexity. A phased rollout allows for quicker initial results and smoother integration into the production line.

Can this system find new, previously unseen defects?

Yes. 🤖 Modern systems use techniques like synthetic data. Generative AI creates images of new defects. This trains the model to find new flaws quickly without needing many real-world examples from the factory floor.

What skills does a team need for this project?

A successful team typically includes:

- Data scientists for model development.

- Machine learning engineers for deployment.

- Subject matter experts for accurate data annotation.

See Also

Unpacking Delivery Exceptions: Resolving Common Shipping Issues and Delays

Revolutionizing Textile Manufacturing: AI's Predictive Maintenance Outlook for 2025

Leveraging Machine Learning: Predicting Fashion Trends to Significantly Boost Sales

Addressing Mis-Shipped Packages: Essential Tips to Resolve and Prevent Errors

Delighting Customers: Implementing Smart Machine Learning for Optimized Orders