AI-driven inspection uses computer vision for garment quality control. This AI technology finds defects in garments automatically. It ensures each garment meets strict quality and compliance standards.

Manual inspection often involves human error, high costs, and slow speeds.

AI-powered inspection offers a solution for modern manufacturing. AI provides better quality control over garments and the entire manufacturing process. The AI helps control quality through consistent inspection. This AI system gives manufacturers superior control over product quality. AI is the future of quality control.

Automating Compliance with AI Technology

AI technology transforms garment manufacturing by introducing intelligent automation into quality control. This system provides a robust framework for enforcing compliance standards automatically. The core of this ai-driven inspection process combines advanced imaging hardware with powerful software. This automation ensures every garment meets precise quality specifications before it leaves the production line.

The Role of Computer Vision

Computer vision forms the foundation of AI-powered defect detection. The process uses a method called Automated Optical Inspection (AOI). High-resolution cameras, such as Line Scan or Area Scan cameras, are positioned along the production line. These cameras capture detailed images of each garment from multiple angles.

The system functions by comparing these captured images against a reference model, or a "golden" sample, which represents a perfect garment.

Powerful lighting illuminates the fabric, ensuring even the smallest flaw is visible. The AI uses these clear images to scan for any differences between the production garment and the perfect reference. This initial step is crucial for gathering the raw data the AI needs for analysis and quality control.

Training Machine Learning Models

An AI is only as smart as the data it learns from. Machine learning models require extensive training to achieve high defect detection accuracy. Developers feed the AI thousands of images, creating a large dataset that includes:

- Examples of perfectly compliant garments.

- Examples of garments with every possible type of defect.

Finding enough real-world defect images is often difficult. To solve this, developers use data augmentation techniques like flipping or rotating images. They also use advanced methods like Generative Adversarial Networks (GANs) to create new, synthetic images of a defect. This process helps the AI learn to identify a wider variety of issues. The AI model, which may use algorithms like Random Forest (RF) or Support Vector Machines (SVMs), learns the difference between acceptable variations and a true defect. This training is essential for reliable defect detection.

Real-Time Defect Detection

Once trained, the AI performs real-time defect detection with incredible speed and precision. As a garment moves through the inspection zone, the AI analyzes its image instantly. The AI-powered defect detection system flags any deviation from the pre-defined compliance rules. The system does not just identify a problem; it specifies the exact type and location of the defect.

For example, the AI can identify numerous stitching defects with high precision:

| Defect Type | AI Detection Description |

|---|---|

| Skipped Stitches | The AI detects gaps where the needle missed the fabric, weakening the seam. |

| Incorrect Tension | It identifies stitches that are too loose or tight, which cause puckering. |

| Broken Stitches | The AI spots fractured threads that compromise the durability of the garments. |

| Misaligned Patterns | It ensures stitch lines follow the intended design path perfectly. |

The AI-powered defect detection system then performs a severity assessment, categorizing each defect as minor or critical. This allows operators to prioritize repairs, reducing rework on minor issues and preventing critical defects from proceeding. This immediate feedback loop gives manufacturers unparalleled control over product quality.

Key Compliance Areas for AI Inspection

An AI system enhances garment quality control by focusing on critical compliance areas. The technology provides detailed inspection across the entire production process. This ensures every garment meets rigorous quality standards before shipment. The AI offers a level of control that is essential for modern manufacturing.

Structural and Seam Integrity

A garment is only as strong as its seams. The AI performs a deep analysis of seam construction to guarantee durability. Using Convolutional Neural Networks (CNNs), the AI identifies structural defects like skipped stitches and open seams with over 90% accuracy. This AI-powered quality control is vital for ready-made garments.

The AI verifies that each seam adheres to specific industry standards. For example, it ensures stronger threads are used for heavy fabrics like denim and finer threads are used for delicate materials. This prevents a common defect that compromises quality.

Fabric and Material Quality

The quality of the material is fundamental to the final garment. AI automates fabric inspection to find even the smallest flaw. The AI system treats the fabric's normal texture as a background pattern. It then identifies any disruption as a potential defect. This method allows the AI to spot numerous fabric defects, including:

- Holes and tears

- Stains and oil marks

- Color variations

- Knots and broken threads

This precise defect detection ensures only high-quality materials are used, which is a key part of quality control. The AI can find a defect that a human inspector might miss.

Measurement and Sizing Accuracy

Inconsistent sizing can damage a brand's reputation. An AI inspection system ensures every garment meets exact measurement specifications. The AI captures an image of the garment and measures critical dimensions, such as chest width, sleeve length, and body length. It compares these measurements against the digital technical specifications. This process guarantees that all garments align with global compliance standards for sizing, providing a consistent fit for consumers. The AI provides total control over sizing quality.

Component and Trim Placement

The placement of logos, buttons, zippers, and other trims defines the professional finish of a garment. The AI confirms that every component is placed correctly. The system references digital tech packs or 3D models to verify the precise location, angle, and alignment of each trim. If a logo is tilted or a button is off-center, the AI flags the defect immediately. This automated check ensures a uniform appearance across all garments and upholds brand quality standards.

Benefits of AI-Driven Inspection

An AI-driven inspection system offers significant advantages for garment manufacturing. It moves quality control from a manual, error-prone task to a data-driven, automated process. This shift delivers measurable improvements in accuracy, speed, cost-efficiency, and traceability. Adopting this technology allows manufacturers to enhance product quality and strengthen their operational framework.

Enhancing Accuracy and Consistency

Human inspection is often inconsistent. Factors like fatigue, subjectivity, and varying skill levels lead to errors. An inspector might miss a small defect after a long shift, or two inspectors might judge the same defect differently. This variability puts quality at risk. AI eliminates these issues by providing objective and tireless inspection.

The AI system operates with machine precision. It applies the same strict criteria to every garment, 24/7. This automation ensures uniform quality assessments across all production runs. An AI can detect subtle flaws, like slight color variations or minor stitch misalignments, that a human eye might overlook. Research shows that human inspectors are prone to accepting poor items and rejecting good ones, especially under pressure. AI minimizes these false positives and negatives, leading to superior defect detection.

AI-powered inspection models deliver higher accuracy and consistency by removing human subjectivity. The AI learns to identify a defect with the highest precision, reducing misclassifications.

Different industries have seen dramatic improvements by adopting AI for quality control. While these examples are not all from garment manufacturing, they show the technology's power.

| Industry | Before AI Accuracy | After AI Accuracy | Key Improvements |

|---|---|---|---|

| Automotive | N/A | Reduced flaws by nearly 40% | Real-time inspection and rapid retraining |

| Steel | ~70% | >98% | Achieved annual savings over $2M |

| Pharmaceuticals | N/A | >97% | Cut inspection cycles by 30% |

This level of accuracy ensures that every garment meets brand standards, enhancing customer trust and satisfaction. The AI provides a reliable control over final product quality.

Increasing Production Throughput

Manual quality control often creates bottlenecks in the production line. Inspectors can only check a limited number of garments per hour. This slows down the entire manufacturing process. AI-driven inspection breaks through these limitations by operating at high speeds.

The system integrates directly into the production line. High-resolution cameras capture images as each garment passes, and the AI analyzes them in real-time. This seamless automation allows for 100% inspection without slowing down production. The AI identifies and classifies any defect instantly, providing immediate feedback. This process helps managers track materials, monitor production, and identify inefficiencies.

This real-time data enables quick decision-making and boosts production efficiency. Key benefits include:

- High-Speed Analysis: The AI performs inspection faster than any human team, supporting mass production demands.

- Eliminating Bottlenecks: By automating quality checks, the AI keeps the production line moving smoothly.

- Immediate Feedback: Operators receive instant alerts about any defect, allowing for rapid corrections and preventing the production of more faulty garments.

This enhanced speed and efficiency allow manufacturers to increase their output while maintaining exceptional quality standards. The AI gives them greater control over production efficiency.

Reducing Rework and Costs

Defects discovered late in the production cycle are expensive. They require costly rework or result in scrapped materials, wasting both time and resources. AI-driven inspection addresses this problem by catching defects early.

By placing inspection points at critical stages of manufacturing, the AI identifies a defect as soon as it occurs. For example, the AI can spot a fabric defect before the material is even cut, or a stitching defect right after a seam is sewn. This early defect detection allows operators to make immediate adjustments.

💡 Proactive Quality Control: AI can prevent 12–20% of potential scrap by identifying process drifts before they lead to major defects. Some tools have demonstrated the ability to cut scrap by 15–30%.

This proactive approach to quality assurance significantly reduces waste. Fewer defects mean less rework, lower material costs, and a more sustainable manufacturing process. The AI helps create a more cost-effective operation by minimizing errors and optimizing resource use. The quality of the final product is improved, and overall costs are reduced.

Ensuring Data-Driven Traceability

In modern manufacturing, traceability is essential for accountability and continuous improvement. Manual record-keeping is often incomplete and difficult to analyze. AI systems solve this by automatically creating a detailed digital record for every garment inspected.

As each garment moves through production, the AI captures and logs quality data at every step. This includes images, defect classifications, and measurement results. This information is integrated with Manufacturing Execution Systems (MES), creating a comprehensive history for each item.

This digital trail offers several key advantages:

- Complete Accountability: Manufacturers have a detailed record of quality controls for every product, which is invaluable for audits and proving compliance.

- Root Cause Analysis: The AI collects and analyzes data from every inspection. This helps identify patterns and trends in defects, tracing them back to a specific machine or operator.

- Continuous Improvement: By understanding the root causes of defects, managers can implement targeted improvements to their processes, enhancing overall quality.

This data-driven approach transforms quality control from a simple pass/fail check into a powerful tool for operational intelligence. The AI provides the data needed to make smarter decisions and build a more resilient manufacturing ecosystem.

Implementing AI in Manufacturing

Adopting an AI-driven inspection system requires a strategic approach. Successful integration transforms quality control from a manual task into an intelligent, automated process. This shift involves careful planning, customization, and team training to fully leverage the power of AI in manufacturing.

Integrating AI into Quality Control Workflows

A smooth integration of AI into existing quality control workflows follows a clear, step-by-step process. This ensures the technology addresses specific manufacturing challenges and delivers measurable results. The typical implementation journey includes:

- Evaluate Current QC Challenges: Manufacturers identify pain points like missed defects or slow inspection speeds.

- Set Clear Goals: They define success with metrics such as reduced defect rates.

- Choose the Right AI Technology: They select a solution that fits their needs and integrates with existing systems.

- Prepare and Integrate Data: They ensure data is clean and structured for the AI to learn effectively.

- Start with a Pilot Project: They test the AI system in a small segment to refine it before a full rollout.

- Train the Team: They educate staff on how to use and interpret AI findings.

- Monitor and Improve: They continuously track performance to enhance accuracy.

- Scale and Expand: They extend the AI system to other operations after a successful pilot.

Customizing Inspection Standards

AI systems offer the flexibility to enforce brand-specific quality standards. Manufacturers can customize the AI to recognize unique defect types or component placements. This level of control allows them to tailor the quality assurance process to their exact product specifications. The AI learns these custom rules, ensuring every garment meets the brand's unique standards for quality.

Training Staff for a New Paradigm

The transition to AI-powered quality control involves a new role for human operators. Staff must be trained to manage the automation and interpret the data the AI provides. Instead of performing repetitive end-of-line QC tasks, employees can focus on process improvement and root cause analysis. This partnership between humans and AI elevates the role of the quality team within the manufacturing environment.

Transitioning to Industry 4.0

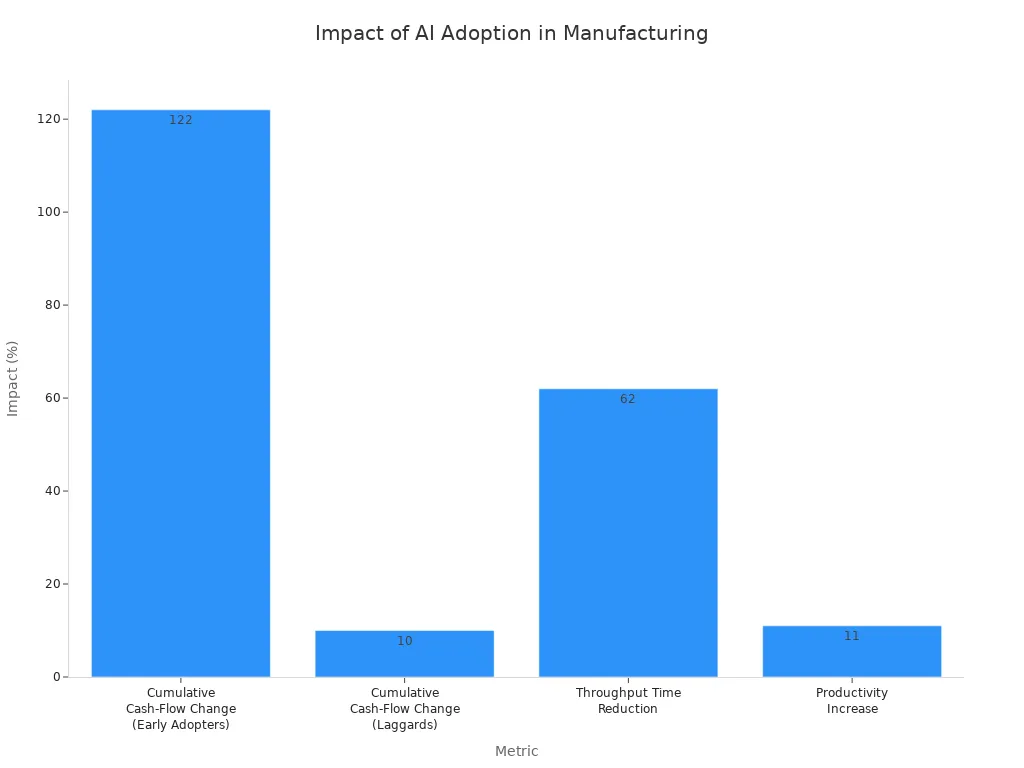

The integration of AI is a cornerstone of the transition to Industry 4.0. AI-powered garment quality control helps manufacturers balance production speed with high-quality delivery. This technology is crucial for creating the smart factories of the future. Early adopters of AI see significant benefits, including major improvements in productivity and cash flow.

By leveraging AI, manufacturing companies can reduce throughput times by up to 62% and increase productivity by up to 11%. This powerful automation gives them a competitive edge and strengthens their entire operation.

AI-driven inspection offers a fast and accurate solution for garment manufacturing. It enhances accuracy, increases speed, reduces costs, and ensures traceability for each garment.

Luxury brands like Versace use this technology to reduce defects in their garments, reinforcing their reputation for premium garment quality.

Manufacturers can gain a competitive edge by adopting this technology. It helps them produce a superior garment and exceed modern compliance expectations.

FAQ

How does the AI learn to identify new defects?

Developers train the AI model with new image data. They feed it examples of the new defect. The system learns the visual patterns. This process allows the AI to accurately detect unique flaws specific to a brand's products.

Is AI inspection affordable for smaller manufacturers?

Yes, options are becoming more accessible. Cloud-based AI services and subscription models reduce large upfront costs. These solutions allow smaller businesses to adopt advanced quality control technology. They can pay as they grow, making it a scalable investment.

How long does it take to implement an AI system?

Implementation time varies. A pilot project can take a few weeks. A full-scale rollout may take several months. The timeline depends on factors like system complexity, data preparation, and integration with existing production lines.

Can the AI inspect complex garments?

Yes, the AI excels at inspecting complex items. It uses multiple cameras and advanced algorithms. The system checks intricate seams, component placements, and detailed patterns. It ensures every part of a complex garment meets precise quality standards.

See Also

Leveraging AI for Proactive Maintenance in the Textile Industry by 2025

The Transformative Impact of AI Sensors on Fashion Supply Chains by 2025

AI-Powered Dynamic Safety Stock: A 2025 Solution for Fashion Retailers

Implementing Smarter AI Solutions to Streamline Fashion Returns Immediately

Optimizing Drop Model Success with Data-Driven Demand Sensing Strategies