Artificial intelligence is a powerful tool for business today. AI automates and optimizes key processes across the entire product lifecycle. Companies that use AI to cut their market time by 50% can see profits increase by 40%. The impact of AI is significant.

PwC predicts AI will halve product development lifecycles. This is how AI reduces lead times. For modern companies, AI provides a clear competitive advantage. AI is essential for growth.

AI in Product Design and Development

The product design and development stage is the first opportunity for a business to gain a competitive edge. Industry reports show that AI innovations can shorten the concept-to-store timeline by up to 40%. This significant reduction comes from using AI to enhance prototyping, analyze market trends, and conduct virtual testing. The right AI tools provide intelligence and agility from the very beginning of the product lifecycle.

Rapid Prototyping with Generative AI

Traditional prototyping is often slow and expensive. Generative AI changes this by creating design iterations at incredible speed. A design process that once took several quarters can now be completed in just six weeks. This acceleration is possible because AI automates repetitive tasks.

- AI-Driven UI/UX Design: Tools like Figma AI can instantly generate layouts and design ideas.

- Sketch-to-Prototype: Platforms such as Uizard can analyze rough sketches and build functional wireframes for rapid testing.

This use of AI allows teams to create and refine concepts much faster than before.

Market and Trend Analysis

Launching a successful product requires a deep understanding of consumer needs. AI excels at analyzing huge amounts of data to find emerging trends. It scans social media, search queries, and online behavior to detect patterns days or weeks in advance. For example, Unilever used AI to identify growing consumer interest in herbal beverages. This insight allowed the company to develop and launch a new tea range in weeks, a process that traditionally took months. This powerful AI capability ensures products align with market demand.

Virtual Testing and Simulation

Physical testing is a major bottleneck in product development. Virtual simulations powered by AI eliminate this delay. Engineers can test thousands of digital models under various conditions before building a single physical prototype. An electric vehicle maker, for instance, used virtual testing to cut costs by 20% and improve energy efficiency by 30%. By simulating user loads and identifying potential issues early, AI reduces lead times and ensures a higher-quality final product. This approach saves time, reduces waste, and optimizes performance.

Smart Manufacturing and Production

The factory floor is where product concepts become reality. Smart manufacturing uses artificial intelligence to make this process faster and more efficient. An AI can analyze production data to find opportunities for improvement. This intelligence transforms traditional production lines into highly responsive systems. The impact of AI is clear across several key areas.

| Area of Improvement | AI Impact |

|---|---|

| Maintenance Costs | Up to 25% reduction |

| Unexpected Downtime | Up to 30% reduction |

| Production Time | 50% reduction |

| Forecasting Errors | 50% reduction |

Predictive Maintenance for Uptime

Unexpected equipment failure stops production and creates costly delays. Predictive maintenance with AI offers a powerful solution. An AI analyzes data from machine sensors to detect signs of a future breakdown. For example, the BMW Group uses an AI system to monitor assembly conveyors. This approach prevents over 500 minutes of unplanned downtime each year. This proactive use of AI keeps machines running, with some companies reporting a 50% decrease in unexpected stops.

Optimized Production Schedules

Creating an efficient production schedule is a complex puzzle. An AI solves this puzzle by processing real-time data from the factory floor. The AI connects to Internet of Things (IoT) devices and manufacturing systems. It knows the status of every machine, material, and worker. This allows the AI to create and adjust schedules instantly. If a problem occurs, the AI finds the best alternative path. This dynamic scheduling ensures production flows smoothly without bottlenecks.

Automated Quality Control

Human inspectors can miss product defects. Studies show manual inspection fails to catch 15% of faults on average. Automated quality control with AI is far more reliable. Using technologies like computer vision, an AI can inspect products with superhuman speed and precision. These systems achieve defect detection accuracy rates between 97% and 99%. This level of quality control ensures only perfect products move forward. This is a critical way AI reduces lead times by preventing rework and waste.

How AI Reduces Lead Times in the Supply Chain

A product's journey from the factory to the customer is full of potential delays. The supply chain is a complex network where speed and efficiency are critical. Artificial intelligence transforms this network into a smart, predictive, and automated system. An AI can process huge amounts of data to predict shipment times and detect equipment problems early. This is how AI reduces lead times and creates a more resilient supply chain.

Demand Forecasting with AI

Inaccurate demand forecasting leads to major problems. Companies either have too much stock (overstock) or not enough (stockouts). AI-powered demand forecasting provides a clear solution. An AI analyzes historical sales, market trends, social media chatter, and even weather patterns. This analysis produces highly accurate predictions.

AI forecasting is a game-changer for inventory management. Companies using AI report a reduction in forecast errors by 30–50%. Some systems even achieve accuracy rates up to 95%.

This level of precision allows businesses to align their inventory perfectly with customer needs. Major retailers already use this technology for a competitive advantage.

| Company | How AI Improves Demand Forecasting |

|---|---|

| Walmart | Processes sales data and supplier inventory to create precise demand predictions and automate restocking. |

| Target | Uses machine learning to combine online and in-store data for a single view of inventory needs. |

| Amazon | Predicts demand to optimize its complex logistics network, reducing stockouts and delivery delays. |

Better forecasting directly impacts the bottom line. AI-driven replenishment can cut inventory carrying costs by 10–15% without affecting product availability. This makes inventory management much more efficient.

Shipping Route Optimization

Logistics planning involves countless variables. Traffic, weather, road closures, and delivery windows can all cause delays. AI-powered shipping route optimization solves this complex puzzle in real time. An AI platform ingests data from GPS, traffic APIs, and weather reports. It compares this live information with historical data to find the fastest, most fuel-efficient route.

This proactive approach enables true supply chain optimization. The AI identifies potential bottlenecks before they happen and instantly suggests alternative routes. This capability offers significant benefits:

- Fuel costs can decrease by up to 20%.

- Delivery times can improve by 25-30%.

- Driver productivity increases.

For example, UPS uses its AI-powered ORION system to optimize routes for its drivers. The system saves the company an estimated 10 million gallons of fuel each year. This shows how AI delivers both cost savings and speed.

Automated Warehouse Management

The modern warehouse is a hub of activity where speed is everything. The use of AI in warehouse management automates and accelerates key tasks. A smart warehouse management system uses AI to coordinate robots, manage inventory, and streamline order fulfillment. The impact of AI in warehouse management is profound, with some facilities increasing order fulfillment speed by up to 300%. The online grocer Ocado is a prime example. Its AI in warehouse management system can process a 50-item order in less than five minutes.

This incredible speed comes from advanced robotics and intelligent software. The AI in warehouse management directs these systems for maximum efficiency.

- Robotic Picking Systems: AI-powered robots identify and retrieve items much faster than humans. This is a core function of AI in warehouse management.

- Collaborative Robots (Cobots): These robots work alongside human employees, assisting with tasks to improve overall workflow. This human-robot collaboration is a key feature of AI in warehouse management.

- Automated Sorting: An AI uses computer vision to sort packages with near-perfect accuracy, a critical part of an advanced warehouse management system.

Companies like Amazon and Geek+ use these technologies to redefine warehouse operations. Their warehouse management system leverages AI to coordinate fleets of robots for picking, sorting, and inventory management. This advanced approach to AI in warehouse management ensures that products move through the facility with unmatched speed and precision. The entire process, guided by AI in warehouse management, minimizes human error and prepares orders for shipment in record time. A modern warehouse management system relies on AI in warehouse management to achieve this level of performance. The future of logistics is tied to AI in warehouse management.

AI in Final-Mile Retail Operations

The final mile is the last step in a product's journey. It is the delivery from a local hub to the customer's doorstep or a retail store. This stage is often the most expensive and complex part of the supply chain. Artificial intelligence is transforming these final-mile operations into a source of speed and efficiency. For example, the delivery company UniUni uses an AI-powered model to optimize routes for its drivers. This approach cut delivery times for clients like Shein from two weeks down to just four or five days. The AI makes the entire process faster and more reliable.

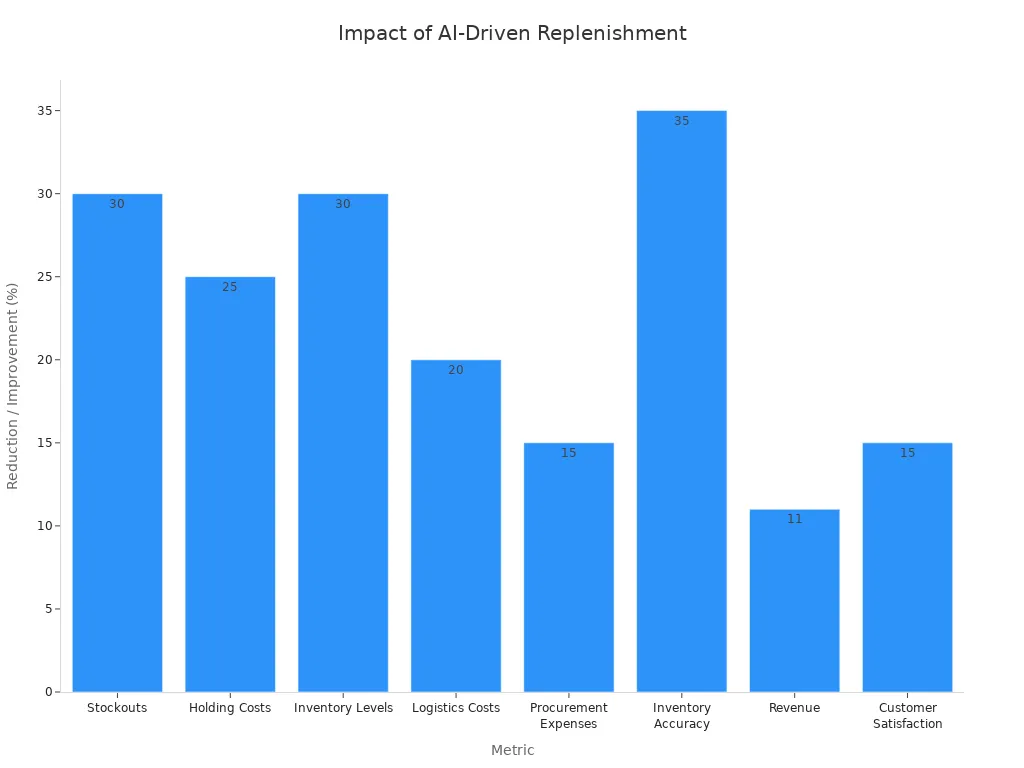

Strategic Replenishment Planning

Getting the right products to the right stores at the right time is a major challenge. Strategic replenishment planning with AI provides a powerful solution. An AI analyzes vast amounts of data to create highly accurate replenishment orders. It looks beyond simple sales history. The system incorporates local events, weather forecasts, and active promotions to predict demand with incredible precision. This consumption-based forecasting allows businesses to respond directly to shifting consumer behavior.

| Metric | Reduction/Improvement |

|---|---|

| Stockouts | 30% reduction |

| Holding Costs | 25% reduction |

| Inventory Levels | Up to 30% reduction |

| Logistics Costs | Up to 20% reduction |

Companies like SupplyHouse.com use AI to improve their day-to-day demand planning. The AI automates tasks and provides better long-term forecast accuracy. This allows the human team to focus on more strategic goals. This level of intelligent inventory management is essential for modern retail.

In-Store Stocking Optimization

An empty shelf means a lost sale. In-store stocking optimization uses AI to make sure that never happens. This technology acts as a constant digital watchdog for store shelves. It uses several key methods to maintain perfect product presentation.

- Computer Vision: Cameras installed in the store capture images of the shelves. An AI analyzes these images to get a real-time snapshot of every product.

- Machine Learning Algorithms: The AI processes the visual data to identify each product. It checks stock levels, reads price tags, and compares the shelf layout to the store's official plan.

- Deviation Detection: The system instantly spots problems. It finds misplaced items, empty spaces, and incorrect price tags. This allows store employees to fix issues immediately.

This use of AI ensures shelves are always stocked correctly. It improves on-shelf availability and supports better inventory management across all store locations. The AI provides the data needed to prevent both stockouts and overstocking, leading to higher sales and less waste.

Real-Time Inventory Tracking

Periodic manual inventory counts are slow and often inaccurate. Real-time inventory tracking powered by AI solves this problem. This technology provides a live, accurate view of stock levels across the entire business, from the warehouse to the store shelf. This constant visibility is a game-changer for inventory management and order fulfillment. The AI achieves this through technologies like IoT sensors and RFID tags.

The improvement in accuracy is dramatic. For instance, AI can boost the accuracy of RFID tracking systems from an average of 63% to over 95%. This precision has a ripple effect on the entire business.

- Faster Response: Companies can react to supply chain disruptions 50% faster.

- Reduced Costs: Retailers like Walmart have used modern inventory systems to cut costs by 25% while increasing sales.

- Improved Order Fulfillment: Accurate data ensures the order fulfillment process runs smoothly, as workers always know exactly where products are located.

This AI-driven approach keeps customers informed with instant updates and notifications about their packages. It also helps businesses predict and avoid delivery problems, such as incorrect addresses. The AI builds a more resilient and customer-focused supply chain.

Artificial intelligence (AI) is more than a single tool. The AI acts as a connective thread across the business. This AI creates a faster pipeline from design to the customer. For companies wanting to stay competitive, integrating AI is essential. This is how AI reduces lead times. The AI helps businesses meet consumer demand effectively. The future of operational excellence will depend on AI. AI is becoming a standard in retail and manufacturing. The strategic use of AI ensures success. AI is the future.

FAQ

How does AI speed up product design?

An ai system accelerates product design significantly. The ai creates many design options very quickly. This ai technology also runs virtual tests. This use of ai saves time and money. The ai helps designers make better choices faster. This ai is a powerful tool for innovation.

Is implementing AI too expensive for small businesses?

Many ai solutions are now affordable. Cloud-based ai services offer pay-as-you-go models. This makes ai accessible without a large initial investment. A small business can use ai for specific tasks. This targeted use of ai provides a strong return. The right ai can level the playing field.

What is the main benefit of using AI in the supply chain?

The biggest benefit of ai is predictive accuracy. An ai analyzes data to forecast demand and optimize routes. This ai reduces delays and cuts costs. The ai makes the entire supply chain more efficient. This ai provides clear visibility from the factory to the customer. This ai is essential.

Will AI replace all human workers in manufacturing?

No, ai is not designed to replace all workers. The ai often works alongside people. This type of ai is a collaborative tool. The ai handles repetitive or dangerous tasks. This allows human employees to focus on creative and strategic work. The ai enhances human capabilities.

See Also

AI Logistics Optimizes Fashion Delivery, Reducing Times Significantly

AI Boosts Production Forecasting Accuracy: 2024 Enterprise Best Practices

AI's Role in Managing Viral Trends Within Fast Fashion

Predicting Your Next Purchases: AI Powers Demand Forecasting

Unpacking Technology's Impact on Supply Chain Execution Efficiency