AI calculates dynamic safety stock by analyzing real-time data streams. This AI inventory optimization adjusts inventory for each product. This next-generation inventory planning is not a static calculation. It is a living system for safety stock management. It adapts to market volatility. This optimisation prevents costly overstock and revenue-losing stockouts. Over 50% of fashion retailers experience stockouts, losing billions. These stockouts can reduce profits by 20%. AI in inventory optimization offers a solution. AI-powered safety stock provides dynamic replenishment. This predictive analytics aids replenishment planning. Better demand forecasting avoids inventory issues. The inventory optimization software offers real-time demand visibility. This AI inventory optimization stops overstock. The system's ai-driven insights guide automated replenishment. This optimization of retail inventory levels prevents future stockouts. The fashion industry's demand for better forecasting and inventory optimization is growing.

Core Models for Dynamic Safety Stock

An effective AI inventory optimization system relies on several interconnected models. These models work together. They transform raw data into actionable intelligence for superior safety stock management. The system's core is its ability to perform deep analysis and forecasting. This leads to precise inventory optimization.

Machine Learning Demand Forecasting

Accurate demand forecasting is the foundation of modern inventory management. AI moves beyond simple historical averages. It uses sophisticated models to predict future sales with much greater accuracy. This advanced forecasting is essential to prevent both overstock and stockouts.

Two primary types of models power this forecasting:

- Time-Series Models: Algorithms like Prophet are ideal for this task. Prophet automatically analyzes historical sales data. It identifies trends, weekly and yearly seasonality, and holiday effects. The model uses a formula,

s(t) = Σ(an cos(2πnt/P) + bn sin(2πnt/P)), to map complex seasonal patterns. This allows the AI to understand recurring demand cycles for each product. This level of forecasting precision is critical for replenishment planning. - Regression Models: These models add another layer of intelligence. They incorporate external factors that influence consumer demand. The AI analyzes data from social media, weather forecasts, and promotional calendars. For example, the system can correlate a spike in social media mentions of a certain jacket with a rise in website visits, predicting a surge in demand. This predictive analytics capability allows retailers to prepare inventory for trends before they peak.

Effective forecasting requires a disciplined approach. It starts with high-quality data and selecting the right machine learning algorithms. The AI models must be retrained continuously with new data to maintain their accuracy. This ongoing optimization ensures the demand forecasting remains sharp.

Achieving Real-time Demand Visibility

Static data leads to poor decisions. Dynamic safety stock requires a live, unified view of demand across all channels. Many retailers struggle here. Studies show 70% still use separate systems for their e-commerce and physical stores. This creates data silos and a fragmented view of inventory and customer behavior. An AI inventory optimization solution breaks down these barriers.

The AI integrates data from every touchpoint to create a single source of truth.

- In-Store Technologies: Brick-and-mortar stores use AI-powered tools for live data collection. RFID tags and smart shelves provide real-time inventory counts. Computer vision cameras act as 'AI eyes'. They monitor how customers interact with products. This helps the AI understand which items are generating interest.

- Unified Commerce Platforms: Modern AI systems connect online sales, mobile app activity, and in-store transactions. They use cloud-based platforms for instant data synchronization. Every sale or return, whether online or in-store, immediately updates the central inventory record. This complete visibility is crucial for accurate AI inventory optimization.

This unified view eliminates the lag between data collection and insight generation. The inventory optimization software has a constant pulse on true market demand. This prevents stockouts in one channel while another has an overstock of the same item.

Lead Time Variability Analysis

Demand is only half of the inventory equation. The other half is supply. Lead time—the time from placing an order with a supplier to receiving the goods—is rarely constant. Delays can happen due to many factors. These include supplier performance issues, transportation delays, and customs clearance problems. This variability makes safety stock management difficult.

AI tackles this challenge by analyzing historical and real-time supply chain data. The AI in inventory optimization learns the performance patterns of each supplier. It identifies early warning signs of potential delays. For instance, the AI can connect the dots between a supplier's dipping quality and a subsequent increase in lead time.

The system's predictive models consider many variables:

- Historical delivery times

- Current transportation routes and port congestion

- Geopolitical events and trade policy changes

- Adverse weather conditions in a supplier's region

This comprehensive analysis allows the AI to generate a precise, dynamic forecast of lead time for every order. This forecasting helps create a reliable buffer, protecting against unexpected delays without causing overstock. The AI-driven insights from this optimization make the entire supply chain more resilient.

Service Level Optimization

What is the perfect in-stock rate? Is it 98%? 95%? The answer depends on the product. An AI inventory optimization system does not treat all items equally. It performs a strategic optimization to set the ideal service level for every single SKU. This ensures capital is invested in the right inventory.

The AI balances two competing costs:

- Cost of Overstock: The capital tied up in unsold inventory, plus storage and potential markdown costs.

- Cost of Stockouts: The lost margin from a missed sale and potential loss of customer loyalty.

For high-margin, strategically important items, the AI may recommend a service level of 98% or higher. For lower-margin or seasonal items, a 92% service level might be more profitable. This granular optimization frees up capital from slow-moving inventory. This capital can be reinvested into products with higher demand.

Leading retailers are already seeing massive returns from this approach.

“Our AI systems now recognize that a store in Miami has fundamentally different inventory needs than one in Stockholm, not just in terms of product mix but in optimal quantities, timing, and even display strategies.” — Helena Helmersson, CEO of H&M Group

By implementing AI for dynamic replenishment and inventory optimization, H&M achieved a 40% reduction in forecasting errors and a 30% increase in profit. The results of this AI-powered optimisation speak for themselves.

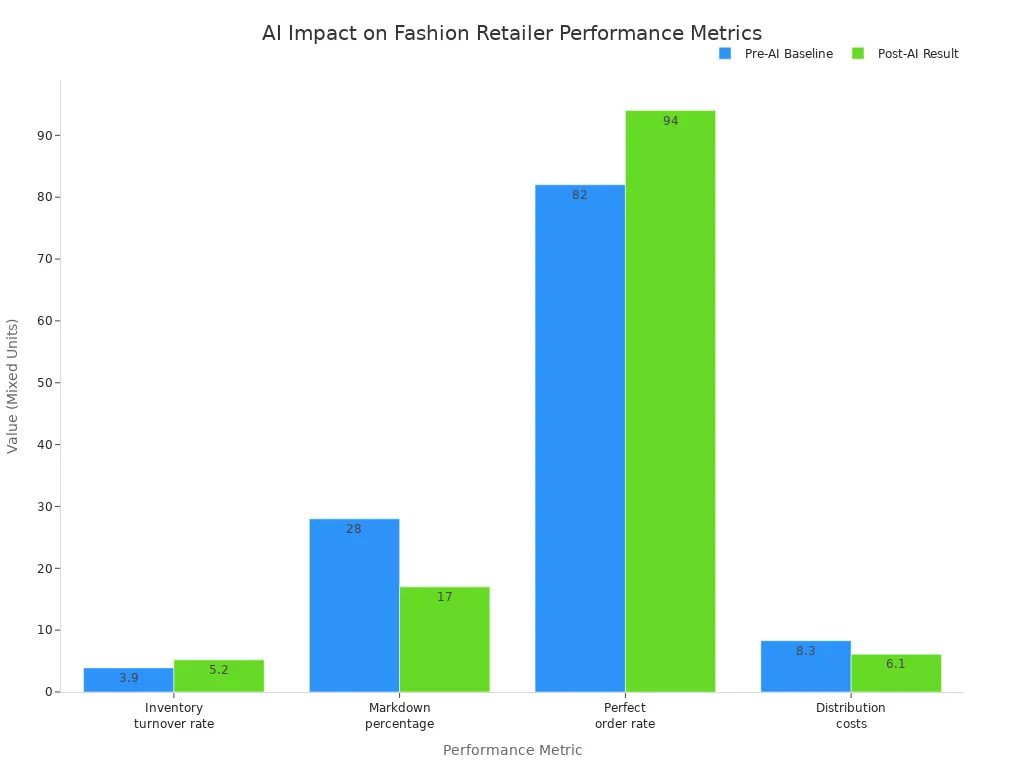

| Metric | Pre-AI Baseline | Post-AI Result | Improvement |

|---|---|---|---|

| Inventory turnover rate | 3.9x annually | 5.2x annually | 33% improvement |

| Markdown percentage | 28% of inventory | 17% of inventory | 39% reduction |

| Perfect order rate | 82% | 94% | 15% improvement |

| Distribution costs | 8.3% of revenue | 6.1% of revenue | 27% reduction |

This level of service level optimization ensures that inventory investments generate the maximum possible return, directly boosting profitability and customer satisfaction while reducing waste.

Implementing Your AI System in 2025

Adopting an AI inventory optimization system is a structured process. Retailers can transform their operations by following a clear, three-step path. This journey moves from foundational data work to full system automation, creating a more resilient supply chain.

Step 1: Data Integration and Preparation

A successful AI inventory optimization project begins with high-quality data. The AI needs clean, centralized information to perform accurate forecasting and optimization. Retailers often face challenges with siloed data sources and inconsistent formatting. Overcoming these hurdles is the first critical step. The AI system requires several key inputs for effective safety stock management.

- Point of Sale (POS) data: This provides transaction details and sales volumes.

- Warehouse Management System (WMS) data: This offers real-time inventory levels and stock locations.

- Supplier feeds: This gives the AI crucial information on lead times and order status.

Gathering this data creates a single source of truth. This unified view is essential for the AI to understand demand and manage inventory effectively.

Step 2: AI Model Selection and Training

With clean data in place, the next step is to select and train the AI models. Cloud-based platforms make advanced inventory optimization software accessible for most retailers. An implementation timeline for AI is typically 12 months. This period allows for careful planning, testing, and deployment to prevent stockouts and improve replenishment planning. The AI models learn from historical data to improve forecasting and demand analysis. This optimization ensures the system can handle complex inventory challenges.

| Stage | Timeline (Months) | Key Activities |

|---|---|---|

| Data Infrastructure | 1-3 | Analyze current systems, improve data quality, establish data integration plan |

| Pilot Project Execution | 4-6 | Select a high-contribution product group, verify AI system effectiveness |

| System Implementation & Expansion | 7-9 | Build enterprise-wide system, incorporate business feedback, prioritize usability |

| Stabilization & Advancement | 10-12 | Strengthen internal capabilities, establish continuous improvement, train operational personnel |

Step 3: System Deployment and Automation

The final step is deploying the AI and automating workflows. The AI inventory optimization system integrates directly with existing Enterprise Resource Planning (ERP) or inventory management software. For example, an AI can connect with NetSuite to analyze demand and optimize retail inventory levels. This integration allows the AI to provide automated stock recommendations. It can also trigger automated replenishment orders when inventory falls below ideal levels. This level of optimisation helps prevent stockouts. The AI continuously monitors inventory, learns from new sales data, and adjusts its own logic. This ensures the inventory optimization software delivers sustained performance, protecting against stockouts and reducing excess inventory.

The Benefits of AI Inventory Optimization

Implementing an AI inventory optimization system delivers transformative results. These benefits extend beyond the supply chain. They directly impact a retailer's profitability, customer loyalty, and financial health. The strategic application of AI creates a clear competitive advantage. This optimization makes fashion retail more agile and resilient.

Reducing Overstock and Markdowns

Excess inventory is a primary drain on profitability. AI inventory optimization directly confronts this challenge. The system's precise demand forecasting prevents the accumulation of slow-moving products. This proactive approach to inventory management is a game-changer. One fast-fashion retailer, for example, reduced its overstock amounts by up to 50% after implementing AI. This level of optimisation stops waste before it happens. The AI achieves this reduction through several intelligent actions.

- Early Identification: AI inventory optimization software identifies slow-moving SKUs early in their lifecycle.

- Dynamic Adjustments: The system dynamically adjusts stock levels and automates replenishment decisions based on real-time demand.

- Strategic Transfers: AI recommends intelligent cross-store product rotations to move inventory from low-demand locations to high-demand ones, preventing deadstock.

This superior inventory control leads to fewer end-of-season markdowns. Retailers can sell a much higher percentage of their goods at full price. Leading brands like Zara use advanced inventory techniques to sell around 85% of items at full price. This figure is significantly above the industry average of 60%. This optimisation of inventory directly boosts margins. AI-driven markdown and dynamic pricing systems can eliminate up to 30% of excess inventory. This helps retailers avoid the deep discounts that erode profits. The AI ensures that overstock becomes a managed exception, not a costly rule.

Minimizing Stockouts and Lost Sales

Empty shelves and "out of stock" messages are silent profit killers. Stockouts lead to immediate lost sales. They also risk long-term damage to customer loyalty. AI inventory optimization provides the visibility needed to prevent these costly stockouts. The AI moves beyond traditional forecasting. It creates highly granular demand forecasts for every single product variation. This includes specific sizes, colors, and styles.

Note: An AI system analyzes short-term demand forecasts, current inventory levels, and recent sales data. These factors are the most influential for accurate stockout prediction. The AI uses this information to protect against stockouts.

This multivariate approach ensures purchase orders reflect actual customer demand. The result is fewer stockouts of popular items. A retailer using AI can see a 10-25% uplift in sales. This increase comes from better product availability. The AI ensures the right products are in the right place at the right time. This level of optimization keeps customers happy and captures maximum revenue. The AI system's ability to predict and prevent stockouts is a core benefit of modern safety stock management. This inventory optimisation protects a brand's reputation and bottom line from the negative effects of stockouts.

Improving Capital Efficiency

Inventory is a significant investment. Every dollar tied up in unsold goods is a dollar that cannot be used elsewhere. AI inventory optimization directly improves a company's capital efficiency. It ensures inventory levels align perfectly with consumer demand. This optimization frees up significant working capital. Retailers no longer need to hold excessive inventory as a buffer against uncertainty.

This newly available capital can be reinvested into critical growth areas:

- Marketing campaigns to attract new customers

- Store renovations or e-commerce platform upgrades

- Research and development for new product lines

- Technology investments to further enhance operations

By reducing overstock and minimizing the need for excessive safety stock, the AI makes the entire business more financially nimble. The inventory optimization software turns inventory from a static cost center into a dynamic, efficient asset. This optimisation creates a virtuous cycle. Better inventory management frees up cash, which fuels growth initiatives, leading to a stronger, more profitable business. This is the ultimate goal of dynamic safety stock and AI inventory optimization.

AI inventory optimization is a definitive solution for retailers. This AI inventory optimization delivers a dual victory. The optimization prevents costly stockouts and manages inventory. The AI uses dynamic safety stock for this optimization. This AI inventory optimization is a key optimization. The inventory optimization software provides this optimisation. This AI inventory optimization prevents stockouts. This AI inventory optimization prevents stockouts. This optimization of inventory prevents stockouts. This optimization of inventory is a key optimization. This optimization of inventory is a final optimization.

FAQ

What is dynamic safety stock?

Dynamic safety stock is an inventory buffer that AI constantly adjusts. The system uses real-time data like sales velocity and supplier lead times. This process helps retailers avoid both stockouts and costly overstock by adapting inventory levels to current market conditions.

How does AI improve demand forecasting?

AI analyzes more than just historical sales data. It incorporates external factors like social media trends, weather patterns, and promotional events. This comprehensive analysis allows the system to predict future customer demand with much higher accuracy for every single product.

Can this AI system work with our current software?

Yes. AI inventory optimization systems integrate with existing software like ERPs and inventory management platforms. The AI provides automated stock recommendations directly within a retailer's current workflow. This seamless connection streamlines replenishment and decision-making without requiring a complete system overhaul.

Is this solution only for large retailers?

Note: Modern AI solutions are not just for large corporations. Cloud-based platforms make this technology accessible and scalable for retailers of all sizes. The systems can adapt to different business needs, helping small and mid-sized businesses compete more effectively.

See Also

AI Sensors Revolutionize Fashion Supply Chains by 2025

Intelligent Fashion AI: Streamlining Product Returns for Immediate Efficiency

Forecasting Retail Inventory: Predictive Analytics Optimizes Re-stocking by 2025

Innovative Fashion AI Solutions: Paving the Way for a Greener Planet

Achieving Equilibrium: Predictive Analytics Harmonizes Fashion Supply and Consumer Demand