By 2025, the integration of AI sensors and the Internet of Things (IoT) will fundamentally transform the fashion supply chain. The textile industry gains complete supply chain visibility through this evolution. This technology enables real-time monitoring and better supply chain management. The fashion sector's production benefits from real-time data and data-driven insights. The textile industry is seeing a major shift.

This technological leap moves the fashion supply chain from a reactive model to a predictive standard. The textile industry now uses data-driven strategies for enhanced production efficiency. This boosts production efficiency, sustainability, and profitability for the fashion textile industry. The IoT provides real-time insights for every production stage in the fashion supply chain.

The role of AI sensors in real-time monitoring

AI sensors and the Internet of Things (IoT) create a new standard for real-time monitoring in the fashion supply chain. These technologies provide the real-time data needed for superior supply chain management. The textile industry gains unprecedented control over production and logistics.

Item-level tracking with smart tags

Smart tags, like AI-enhanced RFID or NFC chips, give every textile item a unique digital identity. This technology enables automated tracking from the production line to the final sale. Brands achieve complete supply chain visibility. For example, Zara embedded RFID chips in its textile products. This system provided real-time insights into inventory, boosting sales significantly. AI algorithms process data from these IoT devices, enabling precise tracking and monitoring. This connectivity allows the fashion supply chain to anticipate delays and manage disruptions effectively. The entire production process benefits from this level of automated tracking.

Quality assurance with environmental IoT

The quality of delicate textiles often depends on their environment. Environmental IoT devices monitor key conditions to protect product quality.

These smart devices use sensors to track temperature, humidity, and light exposure in storage and transit. AI flags any conditions that could damage a textile, such as high humidity that causes mold or UV light that fades colors. This proactive quality control ensures every fashion item reaches the customer in perfect condition.

This real-time monitoring of the production environment is vital for the textile industry. The IoT connectivity provides constant updates on textile quality.

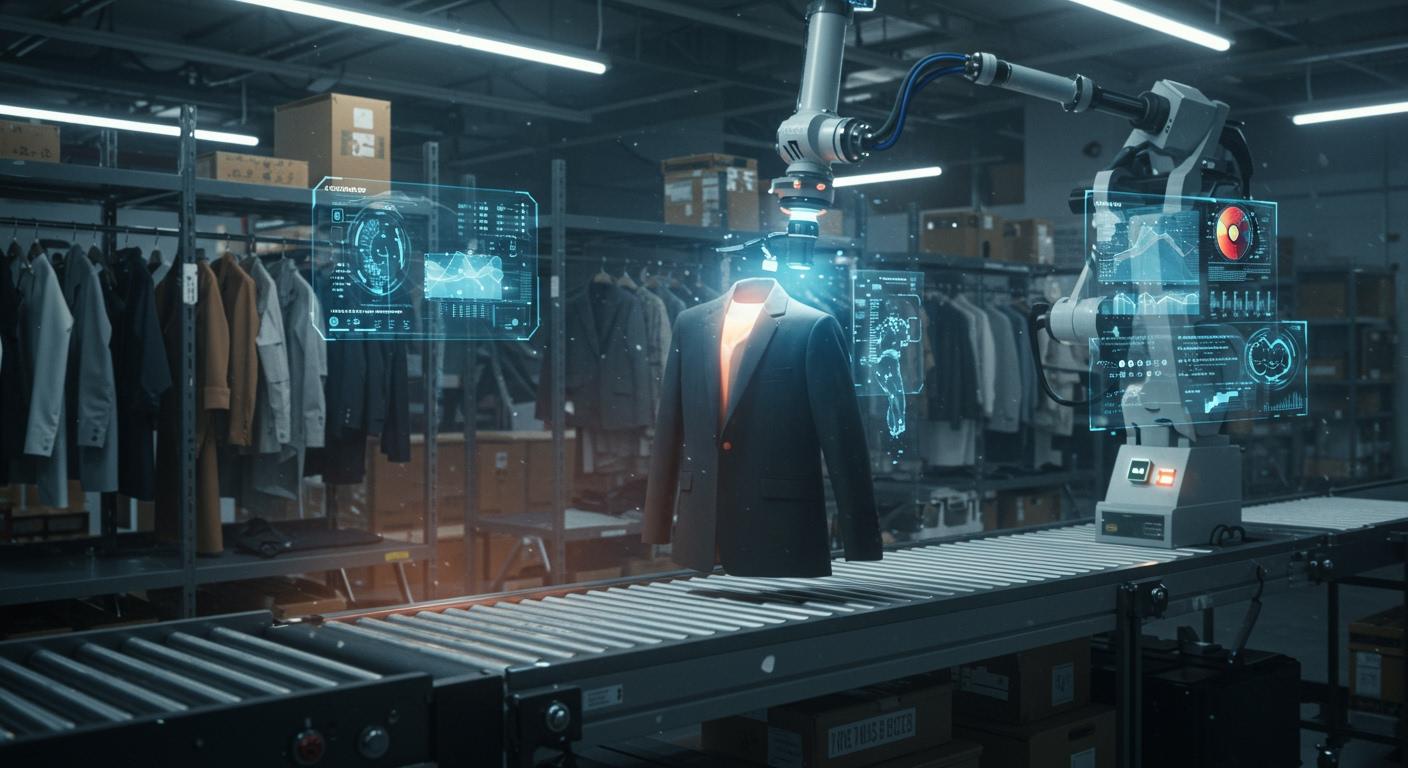

Warehouse automation with computer vision

Computer vision systems act as the eyes of the automated warehouse. These AI sensors streamline complex logistics and improve production efficiency. They offer powerful capabilities for the fashion supply chain.

- Sorting and Packing: Systems can identify product types, read labels, and sort goods for correct storage or shipment.

- Quality Control: Vision devices detect damaged packaging, verify brand logos, and identify incorrect features on a textile.

This technology enhances the quality of warehouse operations. The IoT devices provide the data-driven insights needed for a smarter, more efficient production and distribution network. The textile industry uses these tools for better tracking and monitoring.

Key impacts on the fashion supply chain

The integration of AI and IoT technologies creates transformative impacts across the fashion supply chain. This shift moves brands from reactive problem-solving to predictive optimization. The result is a more efficient, resilient, and profitable production model for the entire textile industry. These technologies deliver tangible benefits in inventory, disruption management, sustainability, and logistics.

Hyper-accurate inventory management

Hyper-accurate inventory management is one of the most immediate benefits. AI sensors provide a constant stream of information, giving brands a precise, real-time view of every single item. This ends the guesswork associated with traditional inventory planning. A fashion brand knows exactly where each textile product is, from the factory floor to the stockroom shelf. This level of supply chain visibility allows for enhanced production efficiency.

AI-powered forecasting models analyze this data to predict demand with incredible accuracy. This capability directly reduces common and costly inventory errors. For instance, a mid-sized apparel brand that adopted AI forecasting cut its excess inventory by 19% and reduced stockouts by half in just three months.

This optimization has a significant financial impact. The textile industry can achieve major improvements:

- AI forecasting can decrease stockouts by 20–50%, ensuring popular items are always available.

- It can also reduce overstock situations by 15–30%, minimizing the need for markdowns on unsold goods.

Proactive disruption mitigation

The modern fashion supply chain faces constant threats, from shipping delays to supplier instability. AI models turn real-time monitoring data into a powerful predictive tool for supply chain management. Instead of reacting to a crisis, companies can anticipate and navigate it. The textile industry gains a critical advantage by foreseeing potential issues.

AI can successfully forecast a wide range of disruptions, giving fashion brands time to adjust their production and logistics strategies.

| Disruption Type | AI Predictive Capability |

|---|---|

| Logistics | Predicts port congestion weeks in advance using satellite and shipping data. |

| Supplier Health | Flags early signs of financial instability in a production partner. |

| Demand Shifts | Anticipates sudden spikes or drops in demand using e-commerce trends. |

| Geopolitics | Models the impact of new tariffs or currency shifts on sourcing costs. |

This proactive stance prevents significant financial loss. For example, RAZE Banking implemented an AI solution that cut fraudulent transactions by 45% and boosted operational efficiency by 30%. This demonstrates how predictive analytics protects assets, a lesson directly applicable to managing a complex fashion supply chain.

Verifiable sustainability with real-time data

Consumers increasingly demand transparency and sustainability. A 2024 PwC survey found that shoppers are willing to spend nearly 10% more on sustainably produced goods. However, they need proof. IoT technology provides the hard data needed to back up sustainability claims, building trust and brand loyalty.

IoT sensors can monitor key metrics throughout the production process, creating an undeniable record of a brand's commitment. AI algorithms then analyze this data to verify compliance.

- Ethical Sourcing: IoT devices track the origin of a textile, ensuring raw materials for smart textiles come from certified sources.

- Factory Conditions: Sensors can monitor water usage, energy consumption, and chemical disposal in real time, confirming a factory meets environmental standards.

- Carbon Footprint: The system measures emissions during production and transportation, providing auditable data for sustainability reports.

This technology makes sustainability a verifiable part of a product's identity. It transforms vague promises into concrete, measurable actions, giving brands a powerful tool to connect with conscious consumers and improve the quality of their operations. The textile industry can use this to build a better future.

Optimized reverse logistics

Returns are a massive challenge for the fashion industry, with the average return costing a retailer 66% of the item's price. AI and IoT offer a strategic solution for the optimization of this process. The goal is not just to handle returns more efficiently but to prevent them from happening in the first place. This is a key area for enhanced production efficiency.

Many returns—up to 70%—are due to poor fit. AI-powered tools directly address this issue.

- Virtual Try-On: Technologies from companies like Fringuant use customer data to provide accurate sizing advice, reducing the likelihood of a return.

- AI Sizing: Major retailers like Zalando now use their own AI tools, where customers take photos to get a precise size recommendation for a textile.

When returns do occur, IoT-tagged smart textiles streamline the process. The supply chain system instantly knows what item is coming back, its condition, and where it needs to go. This real-time insight allows for faster processing and restocking. Furthermore, the data gathered from returns provides invaluable feedback. By analyzing why certain textiles are returned, brands can make smarter decisions about future production, material quality, and design, creating a cycle of continuous improvement. This optimization is vital for the modern textile industry.

A blueprint for implementation

Adopting AI-driven technologies requires a clear and strategic plan. A successful transition for the fashion supply chain depends on thoughtful sensor deployment, robust data integration, and intelligent model activation. This blueprint guides the textile industry toward a smarter, more connected future.

Strategic sensor deployment

The first step involves strategically placing sensor devices across the supply chain. This is not just a technical task but a business decision. A fashion brand must identify critical points for real-time monitoring, from textile sourcing to warehouse operations. However, companies face common challenges.

- High Initial Costs: The investment in advanced devices and infrastructure can be substantial.

- Skill Gaps: Teams need new training to manage the technology effectively.

- Integration Complexity: Connecting new devices with older systems in the supply chain presents a major hurdle for the textile industry.

Careful planning helps a fashion company overcome these issues for a smoother rollout. The right deployment ensures valuable data collection from all key textile processes.

Centralized data platform integration

Individual sensor devices generate streams of information. A centralized data platform is essential to turn this raw data into real-time insights. This platform acts as the brain of the entire supply chain.

A unified system must handle real-time data ingestion and offer a cloud-native architecture for scalability. This ensures all information from different devices is collected and processed together, providing a single source of truth for the fashion supply chain.

This level of connectivity is vital for effective supply chain management. It allows a textile brand to see a complete picture of its operations, from a single textile garment to entire shipments of textiles. This optimization is key for the modern textile industry.

Activating insights with AI models

With a unified data stream, a fashion brand can activate insights using AI models. These algorithms analyze information from ai sensors and other sources to drive decisions. For example, deep learning models like LSTMs can analyze sales data to forecast demand for a specific textile. This predictive power enhances production efficiency and supports inventory optimization. The connectivity between devices and AI creates a responsive system. This system allows the fashion supply chain to adapt quickly to market changes. Validating these models is crucial to ensure the accuracy of the insights and build trust in the technology for managing textiles.

AI sensors are a fundamental necessity for the 2025 fashion supply chain. These technologies provide the real-time visibility required for a resilient supply chain and verifiable sustainability. Brands that delay risk operational disruptions and damage to their sustainability reputation. Early adoption is the key to securing a competitive advantage in the evolving fashion landscape. Investing in this technology future-proofs the entire fashion supply chain, ensuring long-term success and improved sustainability. This is the new standard for the modern supply chain.

FAQ

What is the main benefit of AI sensors for a fashion brand?

AI sensors provide complete, real-time visibility across the supply chain. This capability allows a fashion brand to manage inventory accurately, prevent disruptions, and make smarter, data-driven decisions. It boosts overall efficiency and profitability.

Are these technologies only for large companies?

No, this technology is becoming more accessible. Smaller brands can start with targeted sensor deployments, such as tracking high-value items or monitoring a specific warehouse. This approach provides a scalable entry point for any business.

How do AI sensors improve sustainability?

IoT sensors create a verifiable data trail. They monitor resource usage, factory conditions, and material origins in real time. AI then analyzes this data to confirm compliance with sustainability standards, building consumer trust.

What is the biggest challenge to adopting this technology?

The primary challenges are the initial investment cost and system integration. Companies must connect new sensor technologies with existing legacy platforms. This process requires careful planning and skilled teams to ensure a smooth transition.

See Also

Sustainable Style: AI Innovations for an Eco-Friendly Fashion Future

Anticipating Future Needs: AI-Driven Demand Prediction for 2025

Shaping Tomorrow's Trends: Predictive Analytics in 2025 Fashion Retail

Optimizing Inventory: AI Analytics Harmonizes Fashion Supply and Consumer Demand