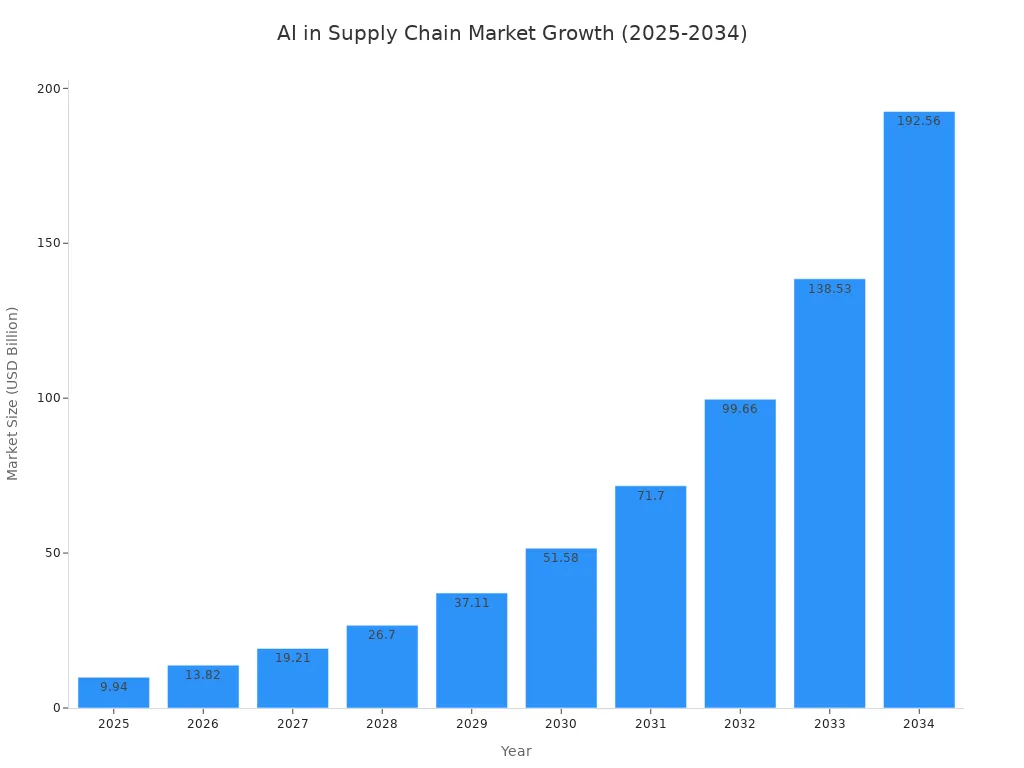

AI-based vendor-managed inventory solves the fashion industry's biggest challenges. This AI technology ends the struggle with overstock and stockouts. AI in inventory management uses predictive analytics for precise demand forecasting. This AI inventory management approach automates replenishment. The AI ensures retailers always have the right products, boosting efficiency. AI inventory management and fashion inventory management are transformed by this AI. The entire supply chain sees improvement. This AI drives inventory optimization and manages stock levels. The growth of AI in supply chain management highlights its impact.

| Metric | Value |

|---|---|

| Market Growth Rate (2025-2034) | CAGR of 39.00% |

| Forecast Period | 2025 to 2034 |

| Market Size in 2025 | USD 9.94 Billion |

| Market Size by 2034 | USD 192.51 Billion |

This analytics-driven AI supply chain is expanding rapidly.

Core AI Strategies for Inventory Optimization

Effective inventory optimization is the foundation of a successful wholesale apparel business. AI introduces powerful strategies that transform inventory from a reactive cost center into a proactive, profit-driving asset. These methods provide the intelligence needed to align supply precisely with market demand. The core of this transformation lies in using AI for predictive analysis and automated execution, creating a more resilient supply chain.

AI-Powered Demand Forecasting

Traditional forecasting often fails in the fast-paced fashion industry. AI-powered demand forecasting offers a superior solution. This approach uses advanced algorithms to analyze complex data sets. It creates highly accurate predictions for future sales. This machine learning forecasting moves beyond simple historical data.

AI systems analyze diverse information sources to understand emerging trends. For example, some services use sophisticated AI to predict product lifecycles.

- They tag items from millions of catwalk images.

- Image recognition technology classifies over 100,000 social media posts monthly.

- This data analysis tracks trends and delivers precise forecasts.

Major apparel companies already see significant benefits. H&M adopted AI-driven demand forecasting to reduce overstocking. The system processes sales data, market trends, and even weather patterns. This change led to less waste and higher customer satisfaction. Similarly, Zara uses AI to analyze sales data and predict trends, allowing the company to replenish popular items quickly. This AI inventory management approach helps Zara sell approximately 85% of its items at full price, well above the industry average.

Dynamic Forecasting with Real-Time Data

Static annual or quarterly forecasts are no longer sufficient. The market changes too quickly. Dynamic forecasting with AI uses a continuous flow of real-time data to update predictions. This ensures that fashion inventory management stays aligned with current consumer behavior. The AI models adapt instantly to new information, providing valuable real-time insights.

Effective dynamic forecasting relies on a wide range of data sources. AI platforms integrate information from multiple points in the supply chain.

| Data Source | Type of Insight |

|---|---|

| Point of Sale (POS) & eCommerce | Live sales velocity and product performance |

| Social Media & Influencer Content | Emerging trends and consumer sentiment |

| Weather Forecasts & Search Trends | External factors influencing purchase decisions |

This method dramatically improves accuracy. AI-driven forecasting can reduce errors by 20-50% compared to older methods. Predictive models learn from new data and refine their algorithms over time. This adaptability allows them to deliver sharper predictions. The result is a more agile supply chain and better decision-making.

Note: AI-powered methods often achieve a Mean Absolute Percentage Error (MAPE) of 5-15%. Traditional methods typically have a MAPE of 15-30%. This improvement in accuracy directly impacts profitability.

The Role of AI in Inventory Management

AI's role extends far beyond forecasting. It revolutionizes the entire practice of ai in inventory management. AI automates routine tasks and provides data-backed recommendations 24/7. This frees up human teams to focus on strategic initiatives rather than manual data entry and analysis. The result is a significant boost in operational efficiency and inventory optimization.

AI platforms can automate a wide range of inventory tasks, leading to better control over stock levels.

- Forecasting agents predict future needs to prevent stockouts.

- Replenishment agents automatically generate reorders based on thresholds.

- Classification agents group inventory by velocity or profitability.

- Anomaly detection agents monitor for irregularities like data mismatches or shrinkage.

These capabilities deliver clear financial benefits. Precise AI predictions reduce excess stock, which lowers carrying costs for space and insurance. Better inventory optimization also minimizes the need for markdowns, preserving profit margins. Ultimately, ensuring product availability captures lost sales and increases revenue. This comprehensive approach to ai in inventory management builds a stronger, more profitable business.

Automated Replenishment and Order Optimization

Automated replenishment is a key feature of ai-based vendor-managed inventory. AI systems monitor inventory levels continuously. They automatically trigger purchase orders when stock drops below a certain point. This process eliminates the guesswork and human error associated with manual reordering. The AI calculates optimal reorder points by analyzing lead times, supplier reliability, and demand trends.

The optimization does not stop there. The AI also determines the best order quantities. It might recommend a bulk purchase to secure a discount. Or, it could suggest smaller, more frequent orders to reduce storage costs and improve cash flow. This intelligent ordering ensures the supply chain remains lean and responsive.

Modern systems use a self-regulating framework. They create a supply chain that adapts to market conditions on its own.

- They use continuous self-correcting loops to refine inventory strategies.

- They process live data from sales and logistics to proactively adjust stock levels.

- They identify potential disruptions for preemptive action.

This level of automation ensures high product availability and minimizes waste. Companies like Relex Solutions and HandiFox offer software that provides these automatic replenishment capabilities, making advanced supply chain management accessible to wholesalers. This machine learning forecasting and replenishment cycle drives efficiency across the entire operation.

Implementing AI-Based Vendor-Managed Inventory

Successful implementation of ai-based vendor-managed inventory requires more than just new software. It demands a fundamental shift in how wholesalers and retailers collaborate. This process involves building a connected data environment, ensuring data quality, and using AI to make smarter decisions about product assortments and allocation. This strategic approach transforms the supply chain into a responsive and efficient network.

Creating a Shared Data Ecosystem

A shared data ecosystem is the backbone of effective AI in inventory management. It connects the wholesaler and its retail partners. This connection allows for the free flow of information. Modern technologies make this real-time collaboration possible. Wholesalers can build a powerful data foundation using several key tools.

- Cloud Platforms: These systems provide a central, accessible location for storing and sharing data. They offer flexibility and scalability for growing operations.

- APIs (Application Programming Interfaces): APIs act as bridges between different software systems. They enable seamless communication between a wholesaler's ERP and a retailer's e-commerce platform.

- Internet of Things (IoT): Devices like RFID tags and smart shelves automate inventory tracking. They provide live updates on stock levels, eliminating manual counts.

- Blockchain Technology: This technology creates a secure and unchangeable record of transactions. It improves traceability and safety throughout the supply chain.

These technologies work together to create a transparent supply chain. Wholesalers and retailers gain a unified view of inventory, sales, and replenishment orders. This shared visibility is crucial for the AI to perform its optimization tasks effectively.

Ensuring Data Integrity for AI Models

An AI model is only as good as the data it receives. Poor data quality leads to inaccurate forecasts and bad business decisions. A retail chain, for example, might face stockouts because of inconsistent inventory data. An e-commerce platform can improve its ai inventory management by standardizing data formats. Consistency means data must be uniform across all systems. Wholesalers must establish strict procedures for cleaning and validating data to ensure the AI performs correctly.

The process of ensuring data integrity involves several key steps. These steps prepare the data for the AI models.

| Step | Action | Purpose |

|---|---|---|

| 1. Data Audit | Assess the current state of all data sources. | Identify quality issues and prioritize cleaning efforts. |

| 2. Data Cleaning | Remove duplicates, correct errors, and handle missing values. | Create a clean and reliable dataset for the AI. |

| 3. Data Integration | Combine data from different systems into a single view. | Provide the AI with a complete picture of the supply chain. |

Note: AI itself can help with data cleansing. AI algorithms can automatically detect spelling errors, identify duplicate records, and even predict missing values based on existing patterns. This use of AI accelerates the data preparation process and improves overall data quality.

AI-Driven Assortment Planning

AI transforms assortment planning from guesswork into a data-driven science. AI agents analyze millions of data points to create product mixes that match real-time demand. This capability allows wholesalers to personalize assortments for specific store locations or customer groups. The result is a level of optimization that traditional methods cannot achieve. This approach is vital for modern fashion inventory management.

Effective AI-driven assortment planning relies on a rich blend of information. The AI considers multiple factors to make its recommendations.

- Historical sales data

- Real-time trend signals from social media

- In-store customer feedback

- Market trends and competitor actions

The AI uses deep tagging to analyze product attributes from images and descriptions. This analysis helps it identify unique style attributes and detect new demand opportunities. This detailed understanding allows the AI to recommend the right products for the right stores, maximizing sales potential and strengthening the entire supply chain. This level of inventory optimization drives profitability.

Optimizing Store-Level Allocation

Once the assortment is planned, the next challenge is allocating inventory correctly across all retail locations. AI excels at this complex task. It optimizes inventory distribution by considering customer demographics, local purchasing patterns, and even transportation costs. This ensures each store receives the right amount of supply to meet its specific demand. The AI makes profit-driven decision-making possible at a granular level.

AI systems use several methods for store-level optimization.

- Predictive Analytics: The AI forecasts demand for each store by analyzing historical sales, weather, and local events.

- Dynamic Adjustments: The AI continuously monitors sales and inventory levels. It automatically adjusts the supply to prevent stockouts or overstocking.

- Capacity Learning: The AI learns each store's physical capacity constraints. This ensures allocation plans are realistic and do not overwhelm a store's storage space.

Major companies have already seen success with this approach. Levi Strauss & Co. uses an advanced AI system to improve demand forecasting and optimize inventory placement. Amazon reduced stockouts by 35% with its predictive inventory system. Walmart uses AI and autonomous robots to manage inventory levels, boosting efficiency and customer satisfaction. This advanced ai inventory management helps wholesalers and their partners build a more resilient and profitable business.

Measuring Success and Overcoming Hurdles

Adopting an AI system requires clear metrics for success and proactive strategies for challenges. Wholesalers must measure performance, protect sensitive data, and implement the technology thoughtfully. This ensures a smooth transition and a strong return on investment. The right approach turns potential hurdles into opportunities for strengthening the entire supply chain.

Key KPIs for VMI Success

Companies must track key performance indicators (KPIs) to measure the impact of AI. These metrics show how well the system is performing. VMI software allows suppliers to monitor these figures and make informed decisions. The goal is effective inventory optimization.

- Inventory Turnover Rate: Measures how quickly stock is sold and replaced.

- Stockout Rate: Tracks the frequency of out-of-stock events.

- Order Fulfillment Accuracy: Shows the percentage of orders delivered correctly.

An AI platform analyzes these metrics to provide valuable insights. This data-driven approach helps reduce carrying costs and increase efficiency.

Monitoring Retailer Sell-Through Rates

Monitoring sell-through rates is essential for success. This KPI reveals how fast a retailer sells a wholesaler's products to the end consumer. A powerful AI system analyzes this data in real time. The AI identifies slow-moving products and can recommend timely markdowns or promotions. This proactive inventory optimization prevents overstock and improves cash flow. The AI ensures inventory remains relevant and profitable.

Addressing Data Security Concerns

Sharing data for ai-based vendor-managed inventory creates cybersecurity risks. Sensitive sales and inventory information requires strong protection. Wholesalers must comply with data privacy regulations to build trust with partners.

Important regulations include the General Data Protection Regulation (GDPR) in Europe and the California Consumer Privacy Act (CCPA). These laws mandate strict security measures for handling personal data. Non-compliance can result in significant fines.

Companies should use encryption and establish clear data-handling guidelines. Regular audits of partners ensure the entire supply chain remains secure.

Starting with a Strategic Pilot Program

A strategic pilot program is the best way to begin with AI. It allows a company to test the technology on a smaller scale. This approach helps identify challenges before a full rollout. A successful pilot proves the value of AI and builds internal support.

- Define a Clear Scope: Start with a specific, manageable problem to show what the AI can do.

- Choose Partners Carefully: Select retail partners with strong data management skills and a willingness to adapt.

- Iterate and Refine: Use ongoing feedback from stakeholders to improve the AI models and processes.

This careful planning mitigates risk and ensures a smoother transition.

The conclusion for the fashion industry is clear. AI-based vendor-managed inventory uses AI for demand forecasting and automated supply. This AI transforms fashion inventory management. The AI in inventory management creates new efficiency. This AI inventory management approach is a strategic shift for the supply chain. It is not just an operational upgrade for supply chain management. The AI builds a more agile supply chain. This AI in inventory management and fashion inventory management is powered by AI. This AI inventory management is critical.

An SVP from a major retailer stated, "Implementing [the] AI-driven customer forecasting model was a game-changer...The impact was immediate—improved...forecast accuracy, stronger margins, and a more agile response to market shifts."

This AI drives inventory optimization. The future of the supply chain depends on this AI and its ability to manage supply. The fashion industry must adapt.

FAQ

What is AI-based VMI?

AI-based VMI uses artificial intelligence (ai) to automate inventory management. The ai system monitors stock levels and automatically creates replenishment orders. This process helps wholesalers manage their partners' inventory more efficiently, ensuring products are always available for customers.

How does AI improve demand forecasting?

The ai improves forecasting by analyzing many data sources. This ai looks at sales history, social media trends, and even weather. The ai finds patterns that humans might miss. This leads to more accurate predictions and better inventory decisions.

Is AI difficult to implement?

Implementing ai requires careful planning. Companies should start with a pilot program to test the system on a small scale. Good data quality is essential for the ai to work correctly. A strategic approach makes the transition smoother and more successful.

What are the main benefits of using AI?

The main benefits of using ai include fewer stockouts and less overstock. The ai also improves order accuracy and increases operational efficiency. This ai helps businesses save money and boost profits by optimizing the entire supply chain.

See Also

Boost Your Business Growth Through Strategic Supply Chain Outsourcing Solutions

Revolutionizing Brand Capacity Planning with Advanced Artificial Intelligence Insights

WarpDriven ERP: Elevating Intelligent Enterprise Management in Supply Chains

Mastering Warehouse Inventory Transfers: Essential Strategies for Optimal Efficiency

Transformative SaaS WMS Benefits: Essential for Modern Warehousing Success