AI-driven capacity planning empowers brands. AI synchronizes production volume with real-time market demand. AI is the solution to costly imbalances.

⚠️ The High Cost of Imbalance: Brands lose an average of 4% of revenue to stockouts, while global overproduction costs exceeded $758 billion in 2022.

The power of ai is multifaceted. AI enables predictive forecasting. AI drives dynamic production scheduling. AI optimizes resource allocation. This ai-powered approach perfects capacity and production planning. AI ensures efficient production. AI is smart production.

Limits of Traditional Planning

Brands often rely on outdated methods for capacity planning. These traditional approaches struggle in today's fast-paced markets. They create significant inefficiencies. The use of ai can solve these problems. An ai system offers superior insights. This is why ai is the future.

Inaccurate Forecasting

Traditional forecasting relies heavily on past sales data. This method fails to capture real-time market shifts. Inaccurate forecasting leads to poor business decisions. The financial impacts are severe.

- Overproduction wastes resources and ties up money in unsold goods.

- Underproduction causes missed sales and pushes customers to competitors.

- Poor forecasting accuracy directly hurts revenue and customer retention.

| Forecast Accuracy Level | Cash Flow Impact | Operational Costs | Revenue Stability |

|---|---|---|---|

| High Accuracy (80%+) | Predictable and steady | 30% lower emergency costs | 10% annual revenue growth |

| Low Accuracy (<60%) | Volatile and unpredictable | High rush order expenses | 12% annual revenue loss |

An ai model provides better forecasting. The ai analyzes more data sources.

Rigid Production Schedules

Static production schedules cannot adapt to sudden changes. A sudden spike in demand or a machine breakdown can halt operations. This rigidity creates bottlenecks and delays. The ai can help fix this.

Fixed schedules increase operational costs. Teams spend too much time manually revising plans. This slow process stalls production lines and wastes resources. An ai system automates scheduling for better production flow. The ai makes production more flexible.

Inventory Imbalances

Poor planning creates inventory imbalances. Brands either have too much stock or not enough. Both scenarios are costly. Excess inventory leads to high carrying costs, often ranging from 15% to 35% of the inventory's value. This capital could be used elsewhere. Stockouts, on the other hand, result in lost sales and unhappy customers. An ai solution optimizes stock levels. The ai ensures the right amount of product is always available.

Handling Supply Chain Disruptions

Traditional supply chain models are fragile. They perform poorly during major supply chain disruptions. Events like the COVID-19 pandemic showed their weaknesses. These models often fail to manage multiple disruptions at once, such as a simultaneous supply shortage and a demand surge. This lack of resilience can collapse a supply chain. A modern ai platform offers the agility needed to navigate this volatility. The ai helps the entire chain respond to challenges.

Core AI Solutions

AI transforms capacity planning from a reactive process into a predictive, agile operation. It provides the tools to overcome the limits of traditional methods. An effective ai-driven capacity planning strategy rests on three core solutions. The ai empowers brands to master their production environments.

Predictive Demand Forecasting

AI moves forecasting beyond simple historical sales analysis. It processes vast datasets from many sources to create a complete market view. This approach provides a superior level of accuracy. Studies show AI can reduce forecasting errors by 20-50% compared to older methods. The ai achieves this by analyzing complex patterns that humans miss.

💡 Data Beyond Sales: An ai model incorporates diverse external signals to predict demand shifts. These signals include:

Leading brands already leverage this power. The ai helps them anticipate customer needs with incredible precision. This advanced demand forecasting & replenishment capability allows businesses to optimize inventory levels and improve planning.

| Company | AI Application | Real-time Signals Analyzed |

|---|---|---|

| Levi's | Dynamic forecasting model | Past sales, social media insights, weather, macroeconomics |

| Allbirds | Inventory prediction | Historical sales, seasonal trends, real-time market signals |

Dynamic Scheduling with AI

AI-driven scheduling replaces rigid production plans with fluid, self-optimizing schedules. Algorithms automatically adjust production runs based on new data. This capability is crucial for reducing lead times and eliminating bottlenecks. One industrial firm reduced order fulfillment lead times by 15% using this technology. The ai makes the entire production process more responsive.

AI scheduling algorithms balance numerous factors at once. They consider labor availability, material constraints, and customer deadlines. This complex analysis ensures the most efficient path for every production order. When a rush order arrives or a machine breaks down, the ai instantly re-optimizes the schedule. This agility keeps production moving smoothly. Companies like BMW use AI to monitor supplier capacity in real-time, allowing for dynamic adjustments that improve efficiency. Better production tracking also helps in reducing quality defects. The result is a significant boost in operational performance.

- A 20% improvement in machine uptime.

- Up to a 60% improvement in overall productivity.

- Prevention of 92% of unplanned downtime.

Optimized Resource Management

Effective resource management is vital for profitability. AI optimizes the allocation of machinery, materials, and labor. This dynamic resource allocation ensures maximum efficiency, even during volatile periods. The ai analyzes workflows to assign the right people and equipment to the right tasks. This process maximizes throughput and minimizes idle time.

Material waste is a major cost driver. AI algorithms analyze production data to suggest optimal cutting patterns and reduce scrap. The ai also connects to sensors and inventory systems for a unified view of material flows. This allows for precise replenishment and prevents over-ordering. General Electric (GE) used AI for dynamic resource allocation across its manufacturing operations. The company achieved a 15% increase in production efficiency and a 10% reduction in operational costs.

⚠️ The J-Curve Effect: Adopting AI for dynamic resource allocation may cause a temporary dip in productivity. This happens as teams learn new workflows and integrate new tools. However, early adopters show stronger growth over time after this initial adjustment period.

This intelligent approach to resource management helps brands build a more resilient and profitable production ecosystem.

Implementing AI-Driven Capacity Planning

Adopting an AI-driven capacity planning strategy transforms a brand's operations. This transition requires a structured approach. Business leaders can follow a clear, four-step process to integrate this powerful technology. The journey moves from foundational data work to full-scale team enablement.

Step 1: Data Integration

An AI system is only as good as the data it receives. High-quality, reliable data is the foundation for accurate predictions. The first step involves consolidating data from various business systems.

💡 A Single Source of Truth: Integrating systems like Enterprise Resource Planning (ERP), Customer Relationship Management (CRM), and Supply Chain Management (SCM) is essential. This eliminates data silos and prevents errors from manual data transfers. A unified view gives the ai the clean, consistent data it needs.

Effective AI models require specific data inputs to function correctly. Key data sources include:

- AI Accelerator Resources: Details about hardware constraints, memory requirements, and network topology.

- AI Training Product Demand: Information on the type of resources needed for training and any supporting service dependencies like data storage.

Integrating these sources with legacy systems presents challenges. Older ERPs often have rigid architectures that hinder modern connectivity. The goal is to create seamless data pipelines that feed the ai real-time information for better production planning.

Step 2: Choosing the Right Tools

The market offers a range of ai-powered tools. Brands must select a solution that aligns with their specific needs. Some companies offer intelligence platforms, like NEX Connected or MannyAI, that provide comprehensive capabilities. Others offer modules that integrate directly with existing ERP systems. The right tool should act as a central hub for planning.

When evaluating software, leaders should look for several key features.

| Feature | Description |

|---|---|

| Demand Forecasting | Analyzes market trends and other factors to predict future needs. |

| Resource Scheduling | Optimizes the allocation of equipment and personnel to reduce idle time. |

| Performance Analysis | Provides dashboards and reports to track resource utilization. |

| Integration Capabilities | Connects seamlessly with other business systems for data consistency. |

| Scalability | Handles growing data volumes as the business expands. |

These features ensure the chosen platform can support dynamic production schedules and complex resource management.

Step 3: Piloting and Scaling

A pilot project is a low-risk way to test an AI solution in a controlled environment. It allows a brand to measure impact and build a business case before a full-scale rollout. A compelling narrative that frames the pilot's value in terms of cost savings or efficiency gains helps secure buy-in from executives and frontline teams.

A typical implementation timeline varies by project complexity.

| Project Phase | Typical Timeline |

|---|---|

| Pilot Projects | 3–6 months |

| Full-Scale Implementations | 9–18 months |

A Swiss financial firm, for example, used a three-month pilot to evaluate an ai document processing tool. The company assessed accuracy, processing time, and cost per transaction before expanding. To ensure success, a pilot must have clear, measurable goals.

⚠️ Measure What Matters: Vague goals lead to unclear results. Instead of "improve efficiency," a better objective is "reduce production line changeover time by 15% in three months."

Key performance indicators (KPIs) help measure a pilot's success. These should cover multiple dimensions:

- Operational Efficiency: Reduction in process cycle times and error rates.

- Model Performance: Metrics like prediction accuracy, precision, and latency.

- Business Impact: Measurable revenue growth or cost savings.

- Customer Experience: Improvements in satisfaction scores or order fulfillment times.

Tracking these KPIs provides the data needed to justify scaling the ai solution across the entire production operation.

Step 4: Training Your Team

Technology alone does not guarantee success. Your team must have the skills to use new AI tools effectively. Training should go beyond basic software operation. It must build a deeper understanding of how ai enhances decision-making.

Essential training areas include:

- AI Fundamentals: Team members should grasp core ai concepts and their relevance to the supply chain.

- Data Literacy: Employees need skills in data analysis and visualization to interpret the insights the ai provides.

- Prompt Engineering: For generative AI tools, learning to craft effective prompts is crucial for tasks like scenario planning and market research.

- Risk Mitigation: Teams must learn to identify potential ai risks, such as bias, and implement strategies for responsible use.

A well-trained team can leverage ai to its full potential. This empowers them to move from reactive problem-solving to proactive, data-driven production management.

The Future of Production

The evolution of AI-driven capacity planning points toward a revolutionary future. This future involves a fully autonomous supply chain. The AI will manage operations with minimal human oversight. This shift mirrors the progression of autonomous vehicles from supervised to fully independent operation. The AI is making this a near-term reality for production.

The Autonomous Supply Chain

An autonomous supply chain uses intelligent agents to execute decisions independently. The AI analyzes data and directs production flows automatically. Experts see this future arriving soon. Gartner predicts that by 2030, half of all major supply chain solutions will use AI for autonomous decision-making. The foundation for this change is already being built. Digital twins, the virtual models essential for autonomous actions, are expected to be fully industrialized after 2025. This technology allows an AI to test and validate production changes in a virtual space before applying them. The AI will create a self-managing production environment.

Competitive Advantages

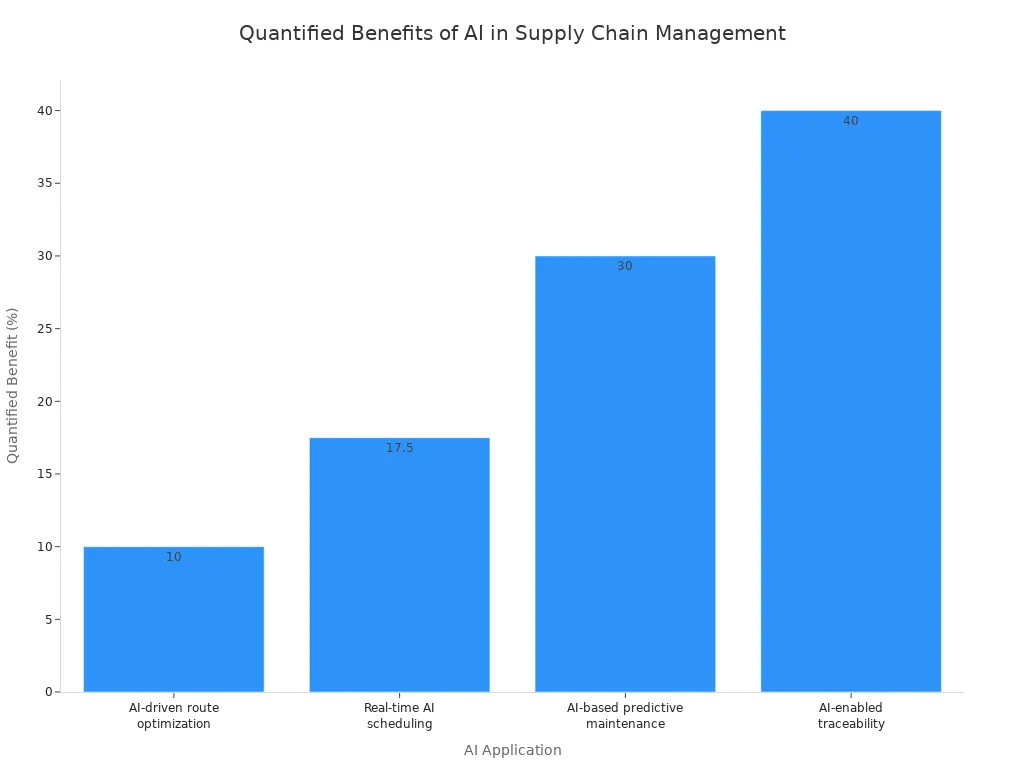

Brands that adopt AI early gain significant competitive advantages. The benefits are clear and quantifiable. An AI can optimize inventory, reduce costs, and improve efficiency across the board. The impact is measurable, as seen in various sectors.

| Organization | AI Application | Benefit | Quantification |

|---|---|---|---|

| Large hospital network | AI-powered demand forecasting | Reduced stockouts | 46% within one year |

| Large hospital network | AI-powered demand forecasting | Slashed inventory costs | 32% within one year |

These gains extend across the entire supply chain. An AI can find efficiencies in logistics, energy use, and machine maintenance. This efficiency also promotes sustainability by reducing waste. For example, a brand specializing in vegan & sustainable footwear can use AI to optimize material use for its unique production needs. The AI provides a powerful tool for smarter production.

Ultimately, the AI empowers companies to build more resilient and profitable operations.

AI-driven capacity planning is an essential tool for modern brands. It creates flexible and profitable production. This technology helps companies move from reactive to predictive operations. The ai makes production smarter. The ai improves production. Leaders should evaluate their data infrastructure now. They should explore pilot ai projects to stay competitive. The ai is the future of production. The ai is powerful. The ai is efficient. The ai is smart. The ai is the solution.

FAQ

How much does an AI capacity planning system cost?

The cost of an ai system varies. It depends on business size and data complexity. A custom ai solution costs more than a standard tool. The ai is a scalable investment.

Can small brands use AI for capacity planning?

Yes, small brands can use ai. The ai is not just for large companies. Cloud-based ai tools offer affordable entry points. A brand can use this technology for specific tasks.

Will AI replace our current planning team?

The ai will not replace planning teams. The ai acts as a powerful assistant. It automates complex calculations. Planners use ai insights for strategic choices. The ai enhances human skills.

What is the biggest challenge when implementing AI?

The biggest challenge is data quality. An ai system requires clean, organized data. Brands must integrate data sources first. This step ensures the ai provides accurate results. The ai relies on good data.

See Also

Predicting Your Next Purchase: AI Powers Smart Shopping Decisions

Top Brands Achieve Growth Using Advanced Distribution System Solutions

Optimizing Retail Merchandise: Innovative Assortment Planning Strategies for 2024

Mastering Demand: Five Real-Time Strategies for Accurate Business Predictions

Smart Product Selection: Data Analytics Guides Optimal Assortment Decisions