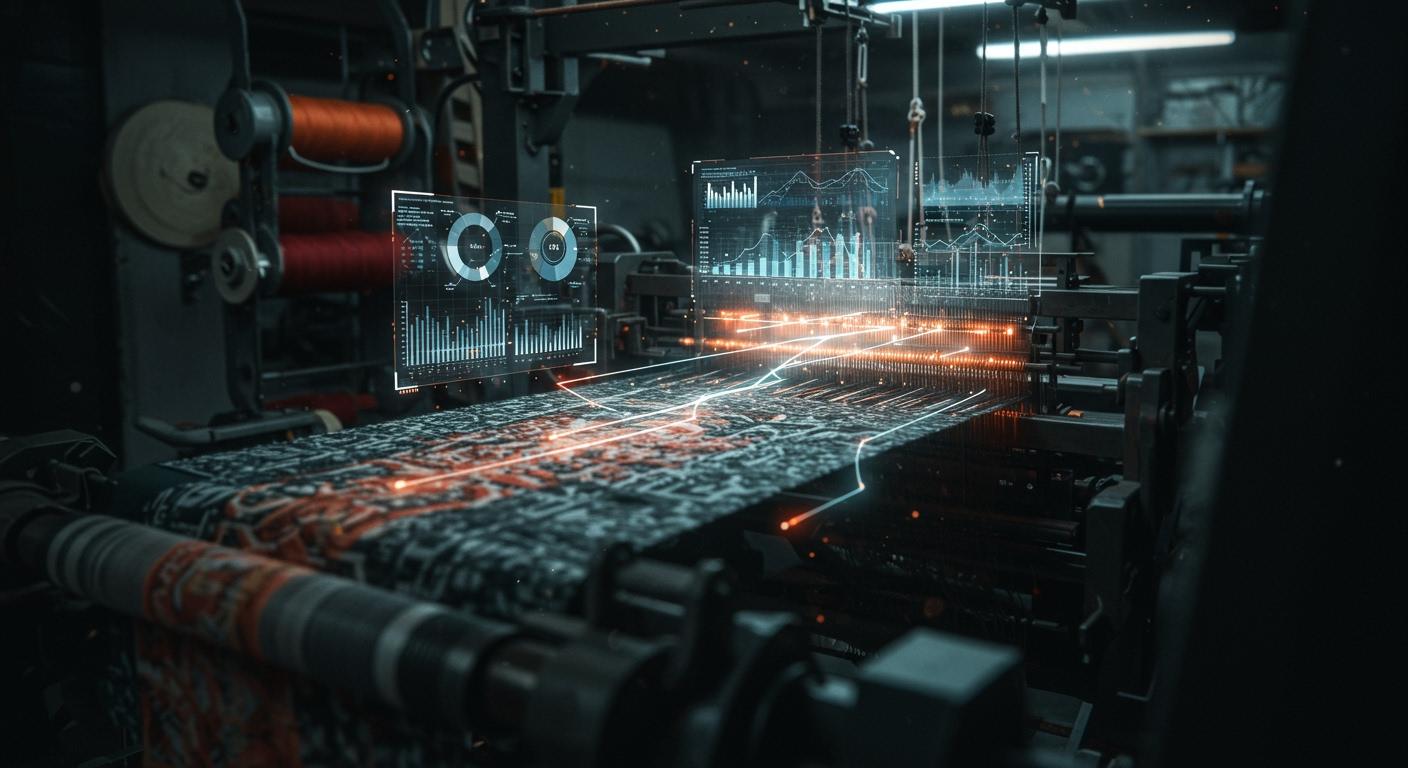

AI analytics revolutionizes textile manufacturing by optimizing how factories use power. This technology provides a clear path to greater efficiency and sustainability.

The global textile industry's energy consumption is significant, accounting for approximately 3% of the world's total energy usage.

Artificial intelligence directly addresses this challenge. AI collects real-time data from textile production machinery. AI identifies patterns of waste in production. AI then predicts demand, and AI automates adjustments to cut waste. These AI applications in textiles make textile production a smarter manufacturing process. AI improves textiles manufacturing. AI enhances the entire production process. AI is vital for modern manufacturing. AI leads to greener manufacturing. AI is the future of textile production.

How AI Analytics Drives Energy Savings

Artificial intelligence transforms energy management in textile manufacturing. AI uses real-time data from smart sensors on equipment. These sensors monitor machines like boilers and dyeing units. The system analyzes consumption patterns to find waste. AI-powered monitoring systems then identify areas for improvement. They suggest real-time adjustments for greater efficiency. This process creates a smarter, more cost-effective production environment.

Predictive Maintenance for Peak Performance

Well-maintained machinery uses less energy. Predictive maintenance uses AI to fix equipment before it fails. AI systems continuously monitor machine parameters like vibration, temperature, and speed. This data helps predict potential breakdowns in spinning frames and looms. Addressing these issues early prevents machines from running inefficiently and consuming excess power. This approach has led to double-digit energy savings in many spinning mills.

This proactive strategy significantly boosts efficiency. For example, a mere 1% reduction in textile machine scrap can lower a mill’s carbon footprint by over 1%. This is because less energy, water, and reprocessing are needed. AI makes this level of optimization possible.

Predictive maintenance can cut unplanned downtime by up to 50%. It can also slash maintenance costs by 10-40%.

This keeps the entire textile production line running smoothly, preventing the energy waste associated with unexpected stops and restarts.

Real-Time Process Control with AI

Many textile processes, like dyeing and finishing, are very energy-intensive. AI provides real-time control over these operations, reducing waste as it happens. For instance, AI applications in textiles include AI-based color-matching systems that optimize dye usage. AI algorithms analyze data on water and energy consumption during dyeing. They automatically adjust parameters to ensure consistent results while minimizing resource use.

| Resource Inefficiency (Energy & Water) | AI Optimization of Dyeing Parameters | Benefits |

|---|---|---|

| Excessive energy for heating/cooling | AI controls temperature and time efficiently | Energy savings and reduced emissions |

| High water usage for rinsing | AI minimizes water through optimized cycles | Less wastewater and reduced treatment costs |

| No real-time process control | AI enables live monitoring and adjustment | Continuous optimization, minimal waste |

A powerful tool for this is the "digital twin." A digital twin is a virtual model of a physical system, like a factory's boiler. It uses real-time data from sensors to simulate operations. This allows manufacturers to test different production scenarios virtually. They can identify inefficiencies, like equipment running during idle periods, and optimize schedules to prevent energy waste before it occurs in the physical world.

AI-powered control panels also provide managers with actionable insights for better decision-making. These systems:

- Track real-time energy consumption and raw material use.

- Adjust labor and material distribution based on demand forecasting.

- Predict potential production issues like machine breakdowns.

- Recommend automated fixes to enhance efficiency.

Intelligent Energy Load Balancing

Energy costs often change throughout the day. Electricity is more expensive during peak demand hours. AI analytics helps textile factories avoid these high tariffs. AI technologies use forecasting algorithms to predict peak demand times. The system can then schedule energy-intensive production tasks, such as running large motors or heating processes, for off-peak hours when electricity is cheaper.

This intelligent scheduling smooths out spikes in energy use. It helps manage and moderate resource consumption across the entire manufacturing facility. By shifting demand, factories not only lower their utility bills but also contribute to a more stable electrical grid. This strategic approach to energy use is a key part of achieving greater energy efficiency and reducing operational costs in textile production. AI applications in textiles make this level of planning and execution seamless, turning energy management from a reactive task into a proactive strategy for reducing waste.

The Core Benefits of AI Integration

Integrating AI into textile manufacturing offers transformative advantages. AI algorithms monitor and regulate energy use with real-time data. This process identifies inefficiencies and suggests improvements. The result is lower operational costs and more sustainable textiles manufacturing. AI is key to enhancing productivity and efficiency across the entire textile production process.

Achieving Significant Cost Reductions

AI directly lowers costs in textile manufacturing. AI systems learn from sensor data to manage power consumption effectively. This leads to significant savings. For example, one textile manufacturer used AI to optimize its ring frame operations. This single change resulted in:

- A 10% reduction in energy consumption.

- Increased profitability from better production efficiency.

- Lower greenhouse gas emissions.

AI applications in textiles create a path to more ecologically friendly and sustainable practices. By reducing waste and optimizing energy, AI helps factories save money and support a greener manufacturing model.

Boosting Operational Efficiency

AI boosts productivity and streamlines operations. AI automation allows machines to run continuously with little human help. This change has increased overall productivity by 20% or more in many mills. AI-powered vision systems also improve quality control. They can spot fabric defects that are too small for the human eye to see consistently. This precision helps mills lower their defect rates by up to 15%. AI optimizes production schedules and improves supply chain efficiency, enhancing productivity and efficiency. This level of AI-driven productivity ensures a smoother, faster, and more reliable production flow.

Enabling Efficient Material Usage

AI is a powerful tool for reducing waste. Efficient material usage is critical for sustainable textiles manufacturing. AI analytics helps achieve this by optimizing two key areas: dyeing and cutting.

AI algorithms analyze fabric data to calculate the exact amount of dye needed. This precision eliminates guesswork, reduces dye waste, and lowers material costs.

In fabric cutting, AI systems create optimal layouts for pattern pieces. This process minimizes scrap material and supports zero-waste designs. AI applications in textiles make efficient material usage a reality. This focus on waste reduction is vital for modern textile production. The technology ensures that every inch of fabric and drop of dye is used effectively, increasing overall productivity and efficiency in manufacturing.

Implementing AI-Driven Manufacturing

Adopting AI-driven manufacturing is a strategic process. It transforms a textile factory's operations. This journey requires careful planning and execution. Success depends on building a solid data foundation, choosing the right tools, and implementing changes gradually.

Step 1: IoT Framework and Data Integration

The first step in using AI is collecting good data. A textile factory must establish an Internet of Things (IoT) framework. This involves placing sensors on machines to gather real-time information. The AI needs high-quality data to work effectively. This data must be integrated from various systems, including Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP).

Effective integration requires clear communication between teams and standardized data formats. This allows different systems to share information smoothly, creating a single source of truth for the entire production process.

This unified data stream gives the AI a complete view of the manufacturing floor. It enables the AI to analyze everything from machine performance to material flow, which is essential for reducing waste.

Step 2: Selecting the Right Platform

Choosing the right AI platform is critical. Companies should first define their business goals. They need to identify specific problems where AI can deliver the most value, such as production inefficiencies or high energy costs. This strategy-first approach ensures the chosen AI technologies align with the factory's needs. The platform should support key ai applications in textiles, from predictive maintenance to supply chain optimization. Management must also plan for challenges.

- High initial costs for software and hardware.

- The need for skilled staff to manage the AI systems.

- Employee resistance to new technology.

Addressing these issues early helps ensure a smoother transition to AI in manufacturing.

Step 3: Pilot Projects and Scaled Rollout

A full-scale rollout of AI should not happen all at once. The best approach is to start with a small pilot project. A textile manufacturer could pilot an AI system on a single assembly line to predict equipment failures. This "lighthouse" approach proves the value of AI on a small scale. Success in the pilot project builds confidence and shows a clear return on investment.

After a successful pilot, the company can create a plan for a phased, factory-wide rollout. This involves training employees and scaling the infrastructure. This systematic implementation minimizes disruption to textile production. It allows the organization to learn and adapt as it expands its use of AI. This method is key for reducing waste and improving the entire manufacturing operation. This is how textiles manufacturing can evolve.

AI analytics is a strategic necessity for modern textile manufacturing, not just another tool. AI delivers significant cost reductions, greater operational efficiency, and improved sustainability. The future of textile production points toward AI-driven micro-factories and automated production.

Adopting AI is the definitive path to a competitive and resilient future. AI transforms the entire textile and textiles manufacturing process, making AI essential for modern manufacturing and the future of textile production. AI is the future of textile manufacturing. AI is key for modern manufacturing.

FAQ

How does AI reduce energy costs in textile factories?

AI systems monitor energy use in real time. They find patterns of waste in machines like boilers and spinning frames. The AI then suggests or automates changes. This process cuts electricity consumption during expensive peak hours, lowering utility bills and improving overall production efficiency.

What is a digital twin in textile manufacturing?

A digital twin is a virtual copy of a factory's physical equipment. It uses live data from sensors to simulate operations.

Manufacturers use this model to test changes safely. They can find ways to save energy without disrupting actual production, making the entire manufacturing process smarter.

Is it expensive to start using AI?

Initial setup costs for AI can be high. This includes new software, hardware, and training for employees. However, many companies start with small pilot projects. This approach proves the value of AI and shows a return on investment before a full-scale rollout, managing costs effectively.

Can AI improve more than just energy use?

Yes, AI enhances the entire production process. It improves quality control by spotting fabric defects. AI also optimizes material usage, reducing dye and fabric waste. This leads to higher productivity, lower operational costs, and more sustainable textiles manufacturing.

See Also

Forecasting Textile Industry Needs: AI-Driven Maintenance Solutions for 2025

Revolutionary AI in Fashion: Sustainable Solutions for an Improved Earth

Optimizing Fashion Returns: Intelligent AI Strategies for Immediate Efficiency

Transformative AI Sensor Technology: Shaping the 2025 Fashion Supply Chain

Achieving Equilibrium: Predictive Analytics Harmonizes Fashion Supply and Consumer Demand