Machine learning and textile technology are creating intelligent fabrics. Artificial intelligence is the key to unlocking the potential of these materials. The ai-assisted development process uses AI to innovate.

Imagine textiles that can monitor your health. These fabrics use embedded sensors, and AI analyzes the data for insights.

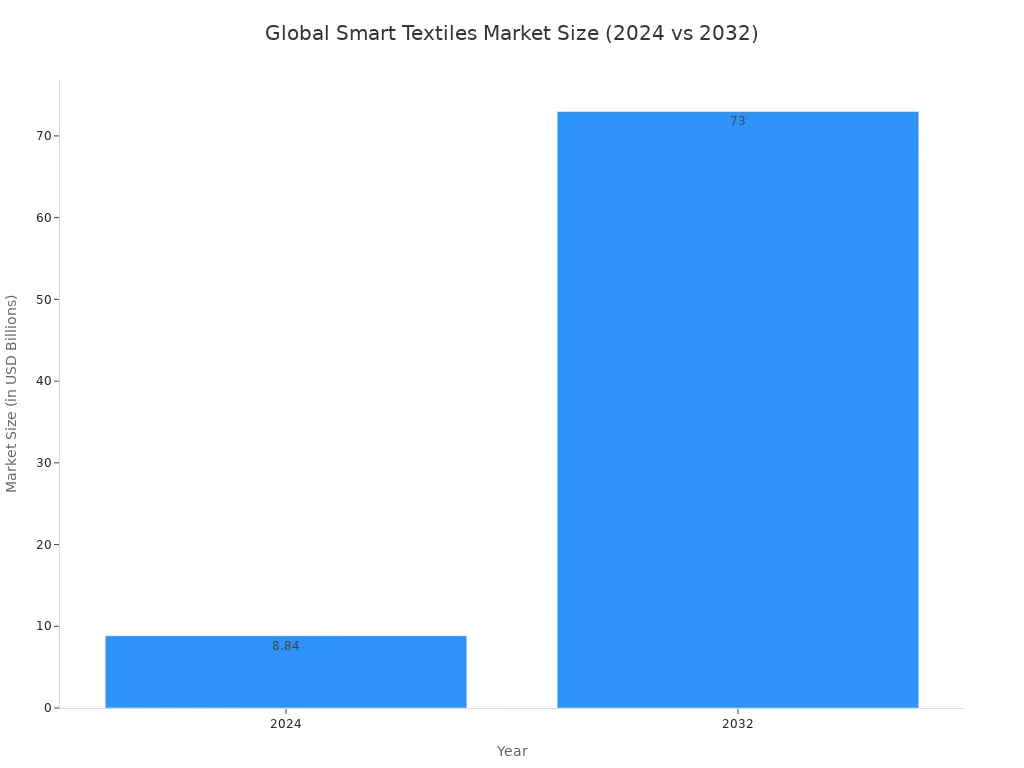

This development drives huge market growth for smart textiles. AI is the engine behind this expansion.

The Blueprint for Intelligent Fabrics

Creating intelligent fabrics starts with a smart design plan. Artificial intelligence provides this blueprint. It redefines how materials are designed and discovered from the very beginning. This ai-assisted development process is foundational to modern e-textile design.

Generative Design for Fabric Structure

Generative design uses AI to create new fabric structures. The AI learns from huge databases of existing textiles. It then generates completely new weave patterns. These AI-generated designs can be optimized for specific qualities. For example, an AI can design a fabric for maximum durability or breathability.

The AI explores countless possibilities much faster than a human designer. It simulates how different fibers and weaves interact. This process helps achieve the best performance before making a physical sample. The AI can even improve a coating's resistance to washing.

This technology allows for incredible creativity and function in textile development. An AI can:

- Create complex new patterns from simple instructions.

- Combine design styles from different cultures.

- Generate technical plans for manufacturing customized clothing.

AI-Driven Material Discovery

Beyond designing patterns, AI accelerates the discovery of new materials. The development of advanced textiles requires innovative components. Machine learning models analyze vast datasets to find promising new materials for e-textile design. This data-driven science helps researchers predict material properties with high accuracy.

The process involves building statistical models. These models predict properties based on a material's structure. The AI then works backward to design a material with the desired traits. This approach has successfully identified new materials for smart textiles. Examples include:

- Graphene nanomaterials

- Next-generation biomaterials

- Conductive polymers for electronics

This use of AI is crucial for creating the next wave of functional fabrics. The AI identifies candidates for everything from biosynthetics to new protein-based fibers.

AI-Assisted Development and Manufacturing

A smart design is only the first step. The next stage involves bringing intelligent textiles to life. The ai-assisted development process transforms digital blueprints into functional fabrics. AI plays a vital role in both the precise integration of electronics and the quality control of the final product. This careful development ensures the textiles are both smart and reliable.

Precision Sensor Integration

Creating a truly smart garment requires placing sensors in exactly the right spots. The placement must capture accurate data without making the clothing uncomfortable. AI models excel at this complex task. An AI analyzes the human body's movement and physiology. It then determines the optimal locations for sensors to collect reliable data. This process is crucial for items like shirts that monitor heart rate or leggings that track muscle engagement. The AI ensures the sensors are effective yet unnoticeable to the wearer.

A key challenge is balancing the number of sensors with performance. More sensors can mean more data, but they also increase cost and can reduce comfort. AI provides a solution. In one study, an AI used Principal Component Analysis to optimize sensor placement. It reduced the number of sensors in a smart garment from 30 to just 10. This optimized set still achieved 99% accuracy in classifying activities. The AI identified the most important pressure sensing points for specific movements. This allows for tailored configurations with fewer components.

This ai-assisted development allows for the integration of highly advanced wearable sensors. The AI helps embed these tiny components directly into the fabric's structure.

These advanced sensors can detect a wide range of information. AI helps integrate various types, including:

- Textile-based electrochemical sweat sensors for glucose and lactate.

- Wearable plasmonic sensors for detailed molecular analysis.

- E-textile sensors for detecting pathogens or hazardous chemicals.

- Specialized pressure sensors for monitoring physiological parameters.

Automated Quality Control

Maintaining high quality is essential during the manufacturing of smart textiles. Even microscopic defects in conductive fibers or sensor connections can cause the entire garment to fail. Human inspection often misses these tiny flaws. AI-powered computer vision provides a superior solution. High-resolution cameras scan the fabric as it is produced. The AI analyzes these images in real time to spot imperfections.

This automated inspection is incredibly accurate. AI systems achieve a success rate of over 90% in defect detection. This is a huge improvement over human inspectors, who are typically 60–70% successful. For very small defects, some AI models like YOLO-v3 show a 20% improvement in precision. The AI can identify broken conductive threads, poorly embedded pressure sensors, or inconsistencies in the material. This ensures every piece of fabric meets strict quality standards.

Automated quality control also makes the manufacturing process more sustainable by reducing waste. The AI system creates a digital "defect map" for each roll of fabric. This allows manufacturers to make smarter decisions.

- The system detects faults early, stopping production before large amounts of material are wasted.

- It optimizes how the fabric is cut to maximize the usable material from each roll.

- The AI provides continuous data, helping operators fix machine issues quickly.

This intelligent oversight is a core part of modern textile development. It guarantees that the final product is not only innovative but also durable and dependable.

AI-Powered Data Intelligence

Intelligent fabrics are powerful data generators. The embedded sensors create a continuous stream of information about the wearer's body and movements. This massive amount of data is useless without a brain to interpret it. Artificial intelligence provides that brain. An AI processes this "big data" in real time. It transforms raw numbers from sensors into meaningful knowledge. This is where the fabric truly becomes smart.

Real-Time Pattern Recognition

The first job for the AI is to understand what the wearer is doing right now. This is called activity recognition. Machine learning models analyze the data streams from various sensors. They learn to identify the unique signatures of different physical movements. For example, the AI can tell the difference between walking, running, and jumping. It does this by analyzing signals from components like Inertial Measurement Units (IMUs) and specialized pressure sensors embedded in the clothing.

An AI system can classify these movements with very high accuracy. It recognizes the distinct electrical resistance changes from strain sensors or motion data from different body parts. This allows the system to categorize a wide range of activities, from simple rest to complex exercises like push-ups or jumping rope. The AI makes this possible by using powerful algorithms. Different algorithms are suited for different tasks.

- Recurrent Neural Networks (RNN, LSTM, GRU) are excellent for recognizing short activities. They understand the time order of sensor readings, like the sequence of a single jump.

- Convolutional Neural Networks (CNNs) are better at finding patterns in long, repetitive activities like running. They can learn deep features from the recurring data.

- Random Forest (RF) is a simpler model. It works well on devices with less computing power, making it great for real-time analysis on low-cost microcontrollers.

This intelligent pattern recognition is the foundation for all other smart features. The AI provides the context for what is happening at any given moment.

Predictive Health and Fitness Analytics

Recognizing activities is just the beginning. The true power of AI lies in its ability to turn data into actionable advice and predictions. The AI translates the raw data from sensors into personalized feedback. This helps users improve their fitness, prevent injuries, and monitor their health.

For fitness, an AI can act as a virtual coach. A smart suit with fabric sensors monitors body movements during a workout. The AI analyzes this data for posture correction. It can tell a user to keep their back straight during a squat, helping to prevent injury. This biomechanical monitoring provides real-time guidance. The AI can also calculate energy expenditure by combining activity recognition with metabolic data, giving a clear picture of workout intensity.

Privacy is a major consideration. Smart clothing collects sensitive health data. Companies must ensure this information is secure. Users are often concerned about how their personal data is stored and used, highlighting the need for strong security and clear privacy policies.

Beyond fitness, AI models can offer predictive health insights. They analyze long-term data to spot trends that may indicate a health risk. For example, a Long Short-Term Memory (LSTM) network can learn from weeks of data to predict future illness symptoms. Other machine learning algorithms process data from pressure sensors to detect changes in posture or joint stress. This allows the AI to forecast the likelihood of an injury. This turns smart clothing into a proactive health tool, offering early warnings and helping people stay healthier.

The Future of Smart Textiles

The journey of intelligent textiles is just beginning. Future developments promise even smarter, more integrated fabrics. Key advancements focus on making these textiles self-sufficient and expanding their use into groundbreaking new fields. The future of these materials depends on solving challenges like data storage and seamless connectivity.

Self-Calibrating Systems

Smart textiles rely on accurate data. However, sensors can lose precision over time due to washing, stretching, and material aging. Self-calibrating systems offer a solution. These systems use adaptive algorithms to maintain sensor accuracy. An AI continuously monitors the data, establishing a baseline and adjusting for any signal changes.

This process works by integrating special circuits and reference sensors directly into the fabric. These components work together to compensate for gradual changes in the material. This ensures that the data collected remains reliable throughout the garment's lifespan. The AI learns the unique performance of the textiles and makes constant, tiny adjustments for consistent quality.

Next-Gen Medical and VR Applications

The future applications for smart textiles are vast, especially in medicine and virtual reality.

In healthcare, these textiles enable powerful remote patient monitoring. Garments with embedded biosensors can track vital signs for patients with chronic diseases like diabetes or heart conditions. This allows for better disease management from home. Startups are already developing medical applications like ECG-monitoring bras that can help signal cardiac issues. These medical applications turn clothing into a non-invasive health tool.

In virtual reality (VR), smart textiles create deeply immersive experiences. Haptic feedback systems woven into clothing can provide nuanced touch sensations, moving beyond simple vibrations.

Imagine feeling a soft tap on your arm or the texture of an object in a game. This technology makes virtual worlds feel more real.

These VR applications use AI to translate game data into complex tactile feedback, blurring the line between the digital and physical worlds. The potential applications are transforming entertainment and training.

Artificial intelligence is the critical element transforming simple fabric into an intelligent system. The AI guides the entire development process. It enables novel material design, ensures manufacturing precision, and interprets complex data from embedded sensors.

This ai-assisted development is paving the way for a connected future. 🤖

The continued development of smart textiles promises a world where our clothing actively enhances health, performance, and daily interactive experiences. These textiles are set to become a seamless part of our lives.

FAQ

How do smart fabrics actually work?

Smart fabrics use tiny sensors woven into the material. These sensors gather data about the body or environment. An AI then analyzes this information. It translates the raw data into useful insights, like activity tracking or health alerts.

Can you wash smart clothing? 🧺

Yes, manufacturers design smart clothing for regular use. The ai-assisted development process helps create durable electronic components and protective coatings. This ensures the embedded sensors can withstand washing and daily wear, making the garments practical for everyday life.

Is the health data from smart textiles secure?

Protecting user data is a top priority. Smart textile companies must implement strong security measures to keep sensitive health information safe.

Clear privacy policies explain how they collect, store, and use personal data. This builds trust with users.

What are the biggest challenges for smart textiles?

The industry faces several key challenges. Developers are working to solve issues related to:

- Creating long-lasting power sources.

- Managing and storing large amounts of data.

- Ensuring sensors remain accurate over the garment's lifespan.

See Also

Sustainable Fashion AI: Innovative Solutions for a Greener Global Future

Textile Industry's Future: AI-Powered Predictive Maintenance by 2025

Apparel's Evolution: Strategic Paths from Manufacturing to Branding Transformation

Optimizing Fashion Returns: Smart AI Solutions for Immediate Efficiency

Fashion Retail's Future: Dynamic AI Safety Stock Solutions for 2025