By 2025, AI predictive maintenance becomes a standard for textile manufacturing. The textile industry moves from a reactive model to a proactive, predictive strategy. This shift uses AI for powerful data-driven insights, boosting operational efficiency.

The global artificial intelligence (AI) in textile market shows this trend. It has a projected growth rate of 32.42% from 2025.

This AI technology enables predictive maintenance for textile manufacturing. AI is key for reducing unplanned downtime. Better quality and less unplanned downtime improve operational efficiency. The predictive power of AI ensures high textile quality. This is the future of textile manufacturing and predictive maintenance.

The Shift to Predictive Maintenance

The textile industry is moving away from old maintenance habits. This change is necessary for modern factories to succeed. The new approach uses AI for predictive maintenance.

Limits of Traditional Maintenance

Traditional maintenance often fails. It reacts to problems instead of preventing them. This reactive model causes expensive delays and repairs. Unplanned equipment failure is a major cost. In the textile sector, these costs are significant.

| Sector | Annual Cost of Unplanned Downtime (UK/EU) |

|---|---|

| Textiles | £2–3 billion |

This old approach creates many challenges. Factories face high costs and use resources poorly. They also struggle with quality control and complex machinery.

Key drivers push textile companies toward change. These include:

- Economic Drivers: Reducing high downtime costs and extending machinery lifespan.

- Operational Drivers: Improving efficiency, ensuring consistent product quality, and meeting sustainability goals.

The Advantage of AI and Data

AI provides a powerful solution. Artificial intelligence uses data to create predictive models. This process turns information into data-driven insights. AI systems perform deep analysis on data from textile machines. This data collection and analysis helps predict when a machine part might fail.

For example, AI monitors spindle vibrations and temperatures on spinning frames. It learns the normal patterns. When a pattern changes, the system alerts technicians before a breakdown occurs. This is the core of predictive maintenance. This automation in textiles allows for smart, data-driven decisions. The results of this shift are impressive. Companies using AI report:

- Up to a 10x return on investment (ROI)

- A 48% reduction in machine breakdowns

- Over 90% accuracy in failure prediction

This predictive power from machine learning makes textile manufacturing more reliable and profitable.

Key Benefits for Textile Manufacturing

Adopting AI for predictive maintenance delivers clear, measurable results. Textile manufacturing companies gain a powerful advantage. They see improvements in machine uptime, product quality, and financial performance. This shift transforms factory floors, enhancing operational efficiency at every stage.

Reducing Unplanned Downtime

The primary benefit of AI predictive maintenance is reducing unplanned downtime. Machines in textile manufacturing run almost constantly. A sudden failure can stop an entire production line. AI systems prevent this. They monitor equipment health in real time. This predictive capability allows teams to schedule repairs before a breakdown happens.

One textile manufacturer saw a 40% reduction in unexpected equipment failures after implementing an AI solution. This proactive approach to maintenance ensures a more consistent production flow. It also lowers the high costs of emergency repairs. This automation leads to higher production efficiency and better use of factory resources.

Expert Tip: Companies using AI for predictive maintenance can lower overall maintenance costs by up to 25%. This comes from fewer emergency repairs and more targeted service work.

This strategy is key to enhancing operational efficiency. It moves operations from a reactive state to a proactive one. The result is an extended equipment lifespan and more reliable production schedules.

Improving Product Quality

Consistent machine performance is essential for high-quality textile products. AI predictive maintenance directly contributes to improving quality control. When machines operate within perfect parameters, they produce better fabric. This helps prevent common defects.

- Correct Tension: AI helps maintain precise yarn tension. This prevents defects like 'Needle Lines' that appear from inconsistent tension.

- Stable Yarn Feed: The system ensures servo feeders deliver yarn consistently. This stops 'Barriness,' an issue caused by irregular feeding.

- Fewer Fabric Holes: AI helps optimize machine settings to reduce high yarn tension. This minimizes dropped stitches and holes in the final textile.

Beyond mechanical issues, AI also improves the dyeing and finishing stages of textile manufacturing. AI-powered vision systems can spot tiny flaws that a human inspector might miss. This technology is crucial for improving quality control and ensuring every yard of fabric meets standards. The predictive system ensures the quality of the final textile product.

| Dyeing and Finishing Error | AI Solution | Benefit |

|---|---|---|

| Subjective Color Matching | AI-Driven Color Analysis | Accurate, repeatable color reproduction |

| Manual Quality Control | AI-Powered Vision Systems | Faster inspections, better defect detection |

| Resource Inefficiency | AI Optimization of Parameters | Lower energy and water consumption |

Optimizing Costs and Resources

AI creates significant cost savings and optimizes resource management. The technology provides data for smarter spending decisions. This impacts everything from spare parts inventory to energy bills. Better resource management improves the overall operational efficiency of a plant.

One major area of savings is inventory management. A predictive system tells you exactly which parts will be needed and when. This allows for optimized maintenance scheduling. According to Oracle, AI can reduce spare parts inventory waste by 25%. This frees up capital and reduces storage costs.

Energy consumption is another area where AI delivers value. AI algorithms analyze energy use across the factory. They identify patterns and suggest improvements.

Predictive AI can reduce energy consumption by up to 30% in industrial plants. It fine-tunes machine settings like speed and temperature to maximize output while using less power. This leads to lower utility bills and more sustainable textile manufacturing.

By reducing unplanned downtime and optimizing machine performance, AI ensures equipment runs at peak efficiency. This comprehensive approach to management provides a clear path to greater profitability and a stronger competitive edge in the textile industry.

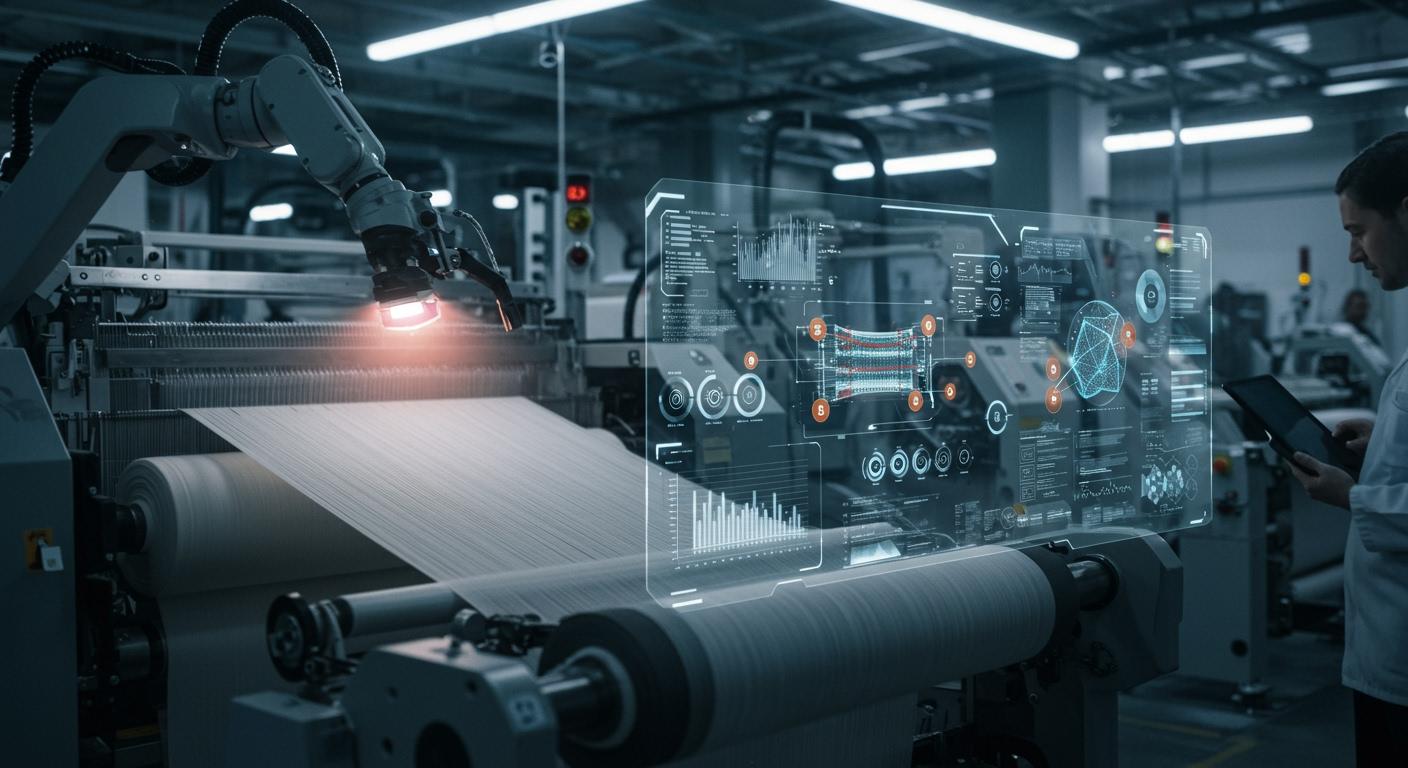

The Core Technology Stack

A successful predictive maintenance strategy in textile manufacturing depends on a strong technology stack. This stack combines hardware for data gathering with smart software for analysis. This combination turns raw machine data into actionable, data-driven insights. The goal is to create a seamless flow of information from the factory floor to the maintenance team.

Essential Tech for Textile Machinery

The foundation of any AI system is data collection and analysis. In textile manufacturing, this starts with sensors placed directly on the equipment. These devices are the eyes and ears of the predictive maintenance system.

- Vibration and Thermal Sensors: These are placed on spinning frames and circular knitting machines. They monitor for unusual vibrations or temperature spikes that signal a future failure.

- Weft Sensors: Used on weaving looms, these sensors detect yarn movement. They can stop a machine instantly if a weft break occurs, which is crucial for improving quality control.

- Hygrometers and Thermometers: These monitor the environment around dyeing machines to ensure optimal conditions for quality textile production.

This constant data collection and analysis process feeds the AI, enabling powerful predictive capabilities and automation in textiles.

Platforms and Analytics Software

The data from sensors flows into a central analytics platform. This is where artificial intelligence and machine learning algorithms perform their analysis. These platforms are the brain of the predictive maintenance operation. Leading systems like Siemens MindSphere and IBM Maximo are designed for this purpose.

The AI uses machine learning to analyze large volumes of data in real time. It identifies complex patterns and automates anomaly detection, which is essential for accurate failure prediction.

These platforms provide key features for modern textile manufacturing:

- Predictive Alerts: The system sends an alert when it predicts a machine part will fail, allowing for scheduled repairs.

- Real-Time Dashboards: Teams can view the health of all equipment from one screen, offering powerful remote monitoring capabilities.

This level of automation and predictive analysis helps a textile company improve quality and efficiency. The intelligence provided by the AI platform is key to a successful predictive maintenance program.

Your 5-Step Implementation Roadmap

Adopting AI predictive maintenance is a structured journey, not an overnight switch. A clear roadmap helps textile manufacturing leaders manage this transition effectively. This five-step plan breaks the process into manageable stages, from a small-scale test to a full factory rollout. Following these steps ensures a smooth implementation and maximizes the return on investment.

Step 1: Launch a Pilot Project

A successful AI journey begins with a small, focused pilot project. This approach allows a company to test the technology and demonstrate its value with minimal risk. The first task is to select the right machines for the pilot. The best candidates are assets that are vital to production or have a history of problems.

| Selection Criteria | Why It Matters for a Pilot Project |

|---|---|

| High Maintenance Costs | Shows a clear and quick financial return. |

| History of Failure | Provides a strong baseline to measure improvement. |

| Critical Role in Production | Highlights the impact of improved uptime on output. |

| Long Lead Times for Repairs | Demonstrates the value of predictive parts ordering. |

Once the pilot machines are chosen, the team must establish clear goals. It is important to measure success with specific Key Performance Indicators (KPIs). This data will build the business case for a wider rollout.

- Cost Avoidance: Calculate savings from preventing failures. This includes lost production value and emergency repair costs.

- Improved Uptime: Track the increase in machine availability. This directly boosts operational efficiency.

- Optimized Maintenance: Measure the shift from reactive repairs to planned work.

- Safety Enhancements: Document any near-misses or dangerous situations that the predictive system helped avoid.

A well-executed pilot project provides proof of concept. It builds confidence and creates momentum for the entire organization.

Step 2: Assess Your Infrastructure

Before deploying AI, a textile factory must evaluate its current technology infrastructure. A successful predictive maintenance program needs a solid foundation for data collection and analysis. This assessment ensures the factory is ready for the new system.

The process involves several key actions:

- Evaluate Current Practices: Review existing maintenance schedules and data readiness.

- Install Sensors: Place IoT sensors on the selected pilot machinery. These devices will capture critical data like vibration and temperature.

- Ensure Connectivity: Confirm that a reliable network is in place to transmit sensor data without interruption.

- Integrate Data: Channel all sensor data into a central platform. This step is crucial for the AI to perform its analysis.

This foundational work prepares the environment for the AI system. It ensures that the data flowing to the machine learning models is clean, consistent, and reliable. Proper infrastructure is essential for the predictive power of AI.

Step 3: Select an AI Partner

Choosing the right technology partner is one of the most important decisions in this process. A good partner offers more than just software. They provide expertise, support, and a solution tailored to the unique needs of textile manufacturing.

Look for a partner with:

- A team of experts in AI, Big Data, and production technology.

- Solutions designed specifically for a factory's equipment, like looms or dyeing machines.

- Fast implementation timelines and 24/7 technical support.

- A system that integrates deep data analysis, machine learning, and computer vision.

When evaluating potential vendors, it is vital to ask detailed questions. These questions help clarify how the partner will support the project long-term.

Questions for Potential AI Vendors:

- Implementation: What internal skills are required to maintain your solution? What training do you offer our team?

- Data Security: How is our data stored and handled? Does our data leave our organization at any time?

- Model Retraining: What data was used to train the AI system? Can we opt our own data out of future model training?

A strong partner will work with the textile company to ensure the AI system delivers on its promise of enhancing operational efficiency.

Step 4: Train Your Team

Technology is only effective when people know how to use it. Training is essential for helping the workforce adapt to an AI-driven environment. The goal is to empower employees, not replace them. The artificial intelligence system should be seen as a tool that helps them perform their jobs better.

Effective training programs for textile workers often include:

- Interactive Learning: Use simulations, augmented reality, and step-by-step tutorials to create a safe learning environment. This reduces the risk of errors during actual production.

- Blended Approaches: Combine formal training with on-the-job experience and peer-to-peer knowledge sharing.

- Customized Content: Tailor training modules to different skill levels. This allows employees to learn at their own pace.

This focus on upskilling prepares the team for technological changes. It helps them understand how AI predictive maintenance improves their daily work, from improving quality control on the production line to making maintenance tasks more proactive. This kind of training builds a culture of continuous learning and adaptation.

Step 5: Scale Strategically

After a successful pilot, the next step is to scale the predictive maintenance program across the entire facility. This phase presents new challenges, including greater technical and organizational complexity. A strategic approach is necessary to manage the expansion.

Common challenges when scaling include:

- Handling a much larger volume of data from more machines.

- Coordinating installations and training across multiple teams.

- Managing an increased number of automated alerts and work orders.

- Tailoring predictive models for different types of textile equipment.

To overcome these hurdles, companies should create a clear change management plan. This plan ensures everyone understands the "what, why, and how" of the new AI system.

Best Practices for Scaling AI:

- Communicate Transparently: Involve employees in the process to build trust and a sense of ownership. Explain that AI is a tool to enhance their jobs.

- Identify Champions: Find enthusiastic employees who can act as AI ambassadors. Their positive experiences can inspire their colleagues.

- Establish Governance: Create clear policies for AI use, data security, and risk management.

- Monitor and Adjust: Track success metrics and be ready to adjust the plan based on feedback and performance data.

By scaling thoughtfully, a textile manufacturing company can successfully integrate AI into its core operations. This transforms the entire organization, leading to sustained improvements in automation, predictive capabilities, and overall operational efficiency.

AI predictive maintenance is an essential strategy for modern textile manufacturing. The AI offers predictive insights. This predictive AI improves operational efficiency. It achieves this by reducing unplanned downtime and boosting textile quality. The pillars of competitive textile manufacturing are superior operational efficiency, enhanced textile quality, and cost-effectiveness from predictive AI. Leaders in textile manufacturing must implement predictive maintenance. The journey to a predictive textile future with AI begins now. This AI ensures high textile quality. The predictive AI enhances textile quality and operational efficiency.

FAQ

How quickly can a company see results?

A company often sees results quickly. A pilot project can show a positive return on investment within 3 to 6 months. The focused scope allows for rapid data analysis. This demonstrates clear improvements in machine uptime and cost savings.

Does AI replace maintenance workers?

AI does not replace maintenance workers. Instead, it enhances their skills. The technology provides data for proactive repairs. This shifts their focus from emergency fixes to strategic planning, making their work more efficient and valuable.

Can small textile companies afford AI?

Yes, small companies can adopt this technology. Many AI partners offer scalable solutions. Subscription-based models lower the initial cost. This makes predictive maintenance accessible without a large upfront investment, allowing smaller operations to compete effectively.

See Also

Forecasting Fashion Trends: Predictive Models Shaping Retail's Future by 2025

AI Sensors Revolutionize Fashion Supply Chains, Driving Efficiency by 2025

Optimizing Retail Inventory: Predictive Analytics for Smart Re-stocking by 2025

Intelligent AI Solutions: Streamlining Fashion Retail Returns for Immediate Impact

Achieving Equilibrium: Predictive Analytics Harmonizes Fashion Supply and Consumer Demand