WarpDriven creates a new level for smart enterprise management. This supply chain ERP lets people work together in real time. AI-powered tools in the platform help companies see real results. WarpDriven supply chain erp links supply chain management, production, sales, logistics, and finance. Teams get data right away, so they can make better choices. Customization options help every business find what works best.

Key Takeaways

Discover WarpDriven Supply Chain ERP

Transform your supply chain with AI-driven real-time collaboration and smart automation. Explore how WarpDriven can boost efficiency and cut costs.

WarpDriven Supply Chain ERP gives real-time data for all supply chain parts. This helps teams make faster and better choices.

AI-powered tools guess what people will need. They help manage inventory and automate tasks. This saves money and makes work better.

The platform works with many product types and global businesses. It is easy to change and connects well with other systems.

Smart alerts and automation stop problems before they get big. This keeps supply chains flexible and dependable.

WarpDriven’s cloud-based system helps businesses grow and change fast. It helps them do well in markets that change quickly.

Real-Time Visibility

End-to-End Tracking

WarpDriven Supply Chain ERP lets you see every step in the supply chain. The platform gathers and updates data from e-commerce, warehousing, production, logistics, and finance all the time. Teams can check products, orders, and inventory right away. They do not have to wait for updates. Old ERP systems update in batches, but WarpDriven updates instantly. Teams always know the real inventory, production, and shipping status.

WarpDriven’s AI-driven architecture works like a smart robot for business. It changes with new information, predicts market changes, and shifts supply chain plans quickly. This helps companies always have the newest data to make good choices.

The table below shows how WarpDriven’s real-time features are better than old ERP systems:

Functional Area | WarpDriven Supply Chain ERP Features | Real-Time Visibility & Dynamic Capability |

|---|---|---|

Data Collection & Synchronization | Always gathers and updates data from e-commerce, warehousing, production, logistics, and finance. | Gives real-time updates for all supply chain work, not like old ERP’s slow batch updates. |

AI & Architecture | Uses smart AI and a special setup for quick decisions and changes. | Lets teams change plans and make smart choices right away, better than old ERP. |

Inventory & Warehouse Management | Supports RFID for fast inventory updates, works with many warehouses, and connects to warehouse robots. | Shows real-time inventory and makes warehouse work faster with instant updates and robots. |

Production Management | Makes new production plans and changes schedules based on real-time needs. | Teams can watch and change production right away, which helps fix problems and save time. |

Full-Chain Collaboration | Shares data from design to delivery, so resources are used well and less manual work is needed. | Makes sure data and teamwork happen in real time across the whole supply chain, making things clear and efficient. |

Demand Forecasting & Optimization | Uses AI to guess demand, pick smart warehouse spots, and improve inventory using sales and logistics data. | Helps teams change inventory and shipping quickly, saving money and stopping waste in real time. |

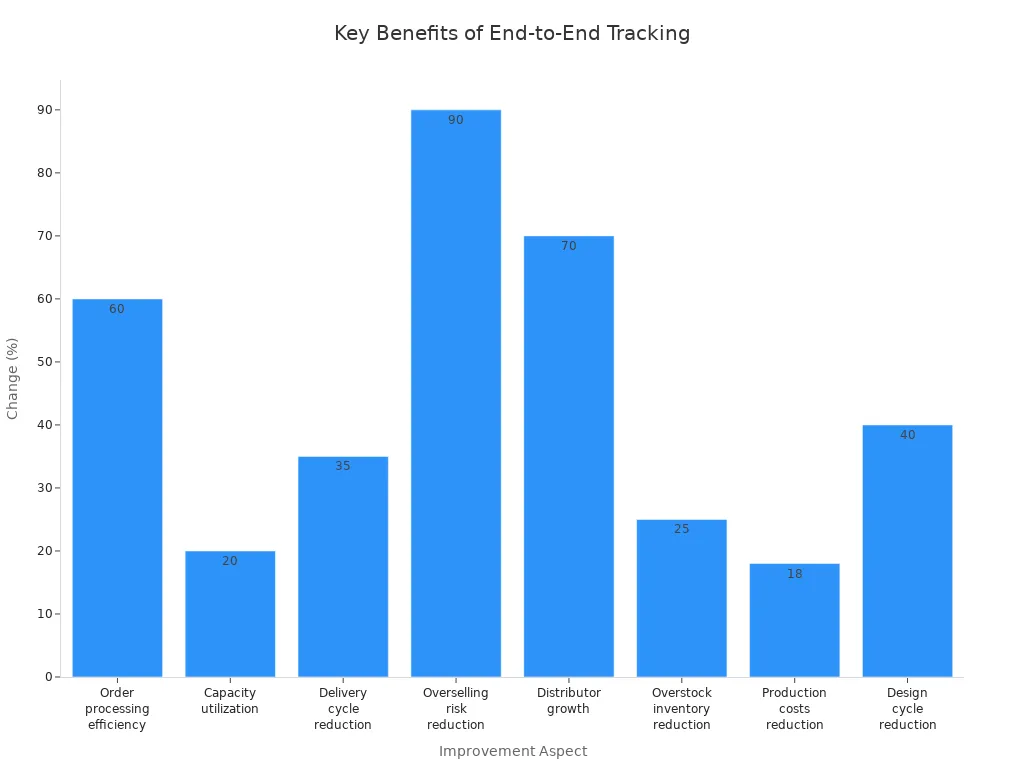

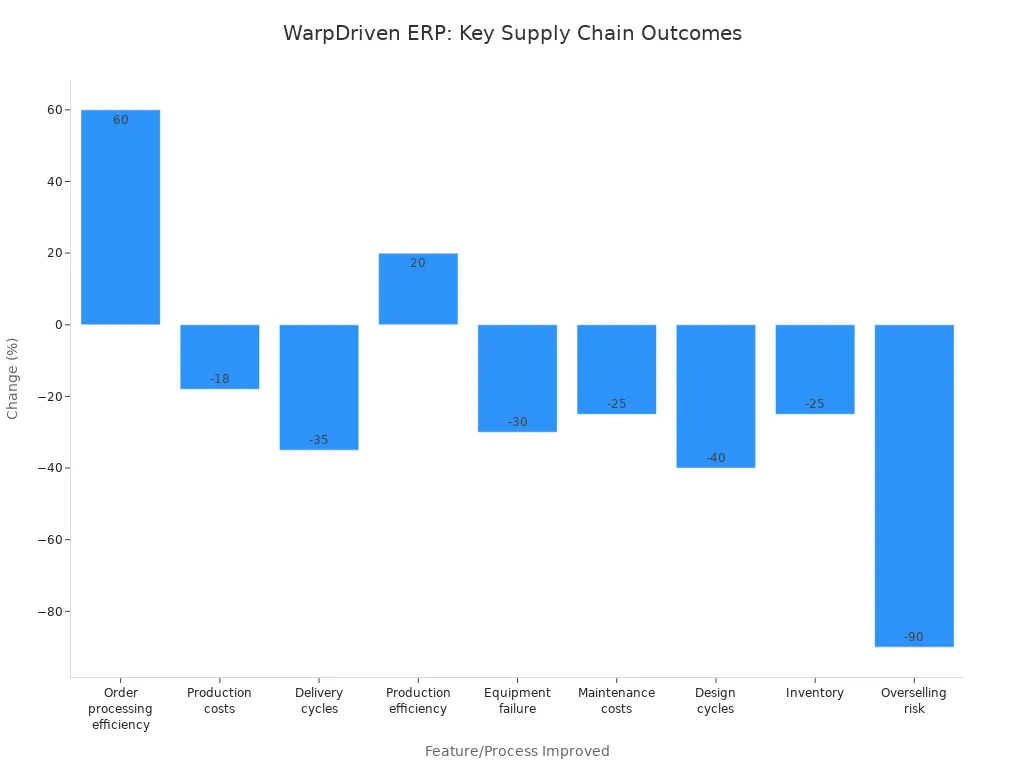

A top Italian fast fashion company used WarpDriven to fix slow and messy distribution. With real-time data, they made order processing 60% faster and cut delivery times by 35%. RFID tracking stopped 90% of overselling. The company also made design cycles 40% shorter and lowered production costs by 18%. These results set a new standard for seeing the whole supply chain.

Proactive Alerts

WarpDriven gives teams alerts before problems happen. The system uses AI to watch supply chain actions and spot issues early. For example, if inventory gets too low, the platform sends a message to the right people. If a shipment is late, the system tells the logistics and sales teams so they can act fast.

These alerts help companies stop big problems. Teams can restock, reroute shipments, or change production plans quickly. This real-time warning helps teams plan better and keep things running smoothly. WarpDriven’s alerts help businesses stay in control and flexible, even when things get tricky.

Integrated Analytics

Unified Data Insights

WarpDriven Supply Chain ERP puts all business data in one spot. Teams from supply chain, production, sales, logistics, and finance see the same data together. This helps everyone work as a team and make fast choices. The platform links product management, inventory, sales, procurement, and finance. Each group can see how the whole business is doing.

The table below shows how sharing data helps teams work better and get good results:

Aspect of Unified Data Insight | Impact on Cross-Departmental Collaboration |

|---|---|

Real-time data synchronization across supply chain, production, sales, logistics, and finance | All teams share the same data, so there are fewer mistakes and faster choices. |

AI-driven operational decisions and full-chain data flow (design to delivery) | Teams use resources better and do not need as much manual work. |

Interconnected modules (product management, inventory, sales, procurement, production, financial management) | Everyone sees the same information, so teams can work together easily. |

Case study: Real-time data synchronization | Order processing got 60% faster. |

Case study: Automated order allocation | Delivery cycles got 35% shorter. |

Case study: RFID tracking | Overselling dropped by 90%. |

Integration of e-commerce, warehouse, production, and logistics data | All departments get up-to-date data, so they talk and work together better. |

Teams using WarpDriven make fewer mistakes and get things done faster. Sharing data helps everyone know what is happening.

Predictive Intelligence

WarpDriven uses smart AI to guess what will happen next in the supply chain. The system looks at old sales, market trends, and what is happening now. It gives tips for inventory, production, and shipping. This helps companies not have too much stock, stop delays, and plan well.

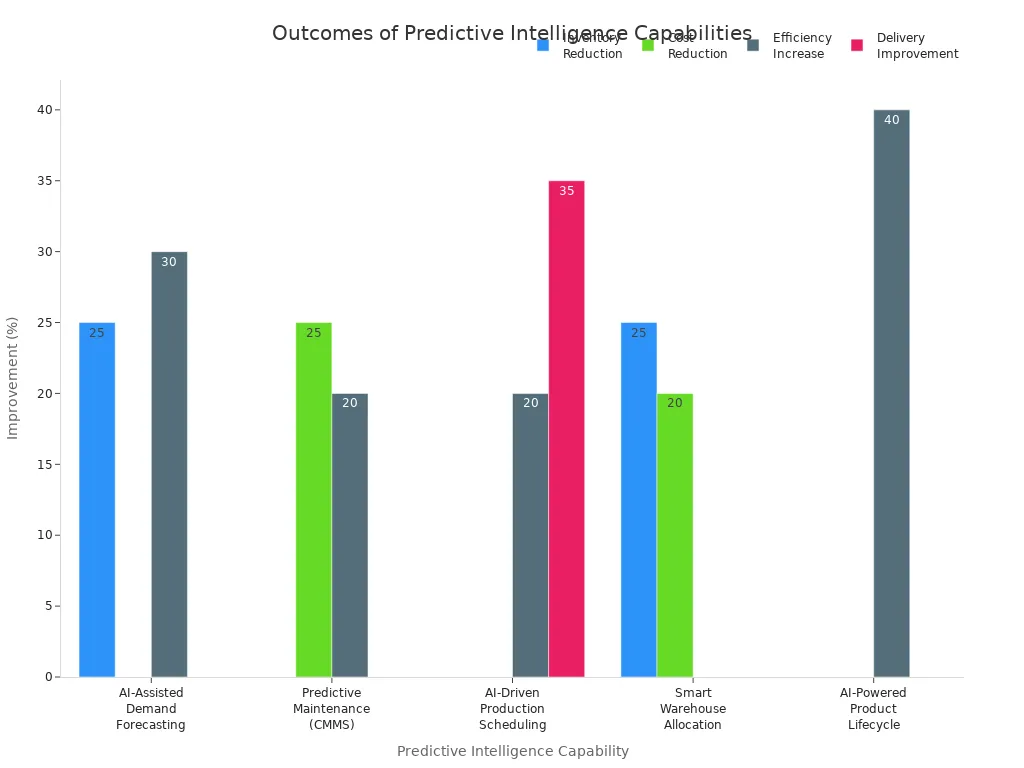

The table below shows important predictive tools and what they do:

Predictive Intelligence Capability | Description | Documented Outcomes from Case Studies |

|---|---|---|

AI-Assisted Demand Forecasting | Looks at old sales and market trends to guess demand and stop too much stock. | Overstock went down by 25%, transport costs dropped, and turnover rate went up by 30%. |

Predictive Maintenance (CMMS) | Plans for fixing equipment before it breaks. | Equipment use went up by 20%, downtime and failures dropped by 30%, and maintenance costs went down by 25%. |

AI-Driven Production Scheduling | Makes new production plans and changes schedules based on what is needed now. | Delivery cycles got up to 35% shorter, lead times dropped by 25%, and production got 20% better. |

Smart Warehouse Allocation & Inventory Optimization | Makes warehouse layouts and inventory better using sales, costs, and demand. | Transport costs dropped by 20%, unsold inventory went down by 25%, and orders got closer to markets. |

AI-Powered Product Lifecycle Management | Gives design ideas and product tips using user and market data. | Design cycles got 40% shorter, more products did well, and influencer partnerships tripled. |

With WarpDriven, companies use data to make better choices. The platform’s smart tools help businesses stay ahead, save money, and work faster.

Intelligent Automation

Workflow Optimization

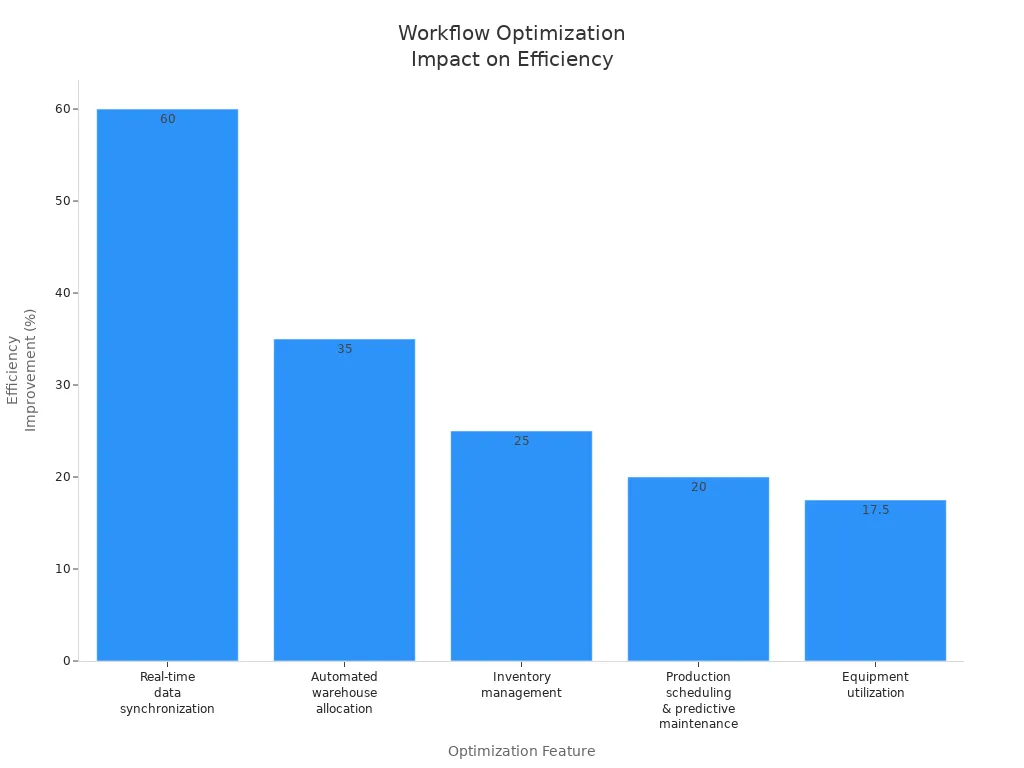

WarpDriven Supply Chain ERP uses smart automation to help businesses work faster. The platform links all parts of the supply chain, from product management to delivery. Teams get updates right away and can act fast. Automated workflows mean less manual work and fewer mistakes.

The table below shows how WarpDriven’s workflow optimization features help teams work better:

Optimization Feature | Measurable Improvement | Impact on Process Efficiency |

|---|---|---|

Real-time data synchronization | Orders are handled faster and there are fewer delays | |

Automated warehouse allocation | 35% reduction in delivery cycles | Deliveries are quicker and logistics work better |

Inventory management | 25% decrease in overstock inventory | Companies save money and waste less |

Production scheduling & predictive maintenance | 20% increase in production efficiency | Machines work more and stop less |

Equipment utilization (via predictive maintenance) | 15-20% gains in equipment utilization and OEE | Resources are used better and machines break less |

AI-assisted demand forecasting | Reduced overstock risks and improved turnover | Supply matches demand more closely |

Full-chain collaboration | Streamlined design to delivery process | Less manual work and teams can change plans quickly |

Teams using WarpDriven see orders move faster and have fewer slowdowns. Automated warehouse tools help deliveries arrive sooner. Inventory tools help companies keep just enough stock. Production scheduling and predictive maintenance keep machines working and stop them from breaking down. All these features help the supply chain work better.

AI-Driven Forecasting

WarpDriven’s AI forecasting tools help companies plan ahead. The system checks sales history, market trends, and current data to guess what will happen next. This helps teams make good choices and stop problems before they start.

Real-time updates for product, inventory, and logistics keep everyone informed.

Smart warehouse layouts save money and cut down on old stock.

AI demand forecasting helps guess what customers want.

Automated production scheduling changes plans as needed.

Predictive maintenance keeps machines working longer.

Full-chain collaboration links design, production, and delivery.

The AI decision engine gives tips to make things better.

With these tools, companies match supply with demand and waste less. They can also react fast when things change. WarpDriven’s smart automation helps businesses do better in today’s busy world.

WarpDriven Supply Chain ERP Advantages

Multi-Variant Product Management

WarpDriven Supply Chain ERP helps companies with many product types. It lets teams watch inventory, prices, and sales for lots of product choices. These can be different colors, sizes, or features. This is very helpful for fashion, medicine, and factories. These businesses have many products and fast changes.

The system lets teams set up, check, and change product info right away. AI tools write product details and ads, so people do less work. This keeps things the same every time. Companies can make new products fast and follow market trends. They can also handle the whole product life easily.

WarpDriven’s multi-variant management helps companies deal with many SKUs, launch products faster, and stop mistakes.

Industry customization is a big plus. WarpDriven fits the needs of clothes, food, dairy, drinks, online sellers, and global shipping. The platform works for B2B, B2C, and M2C. It connects with online shops and other sellers. Flexible shipping, like dropshipping and fulfillment, makes work easier.

The table below shows how WarpDriven’s main parts help with many product types and easy erp integration:

Core Modules & Features | Description |

|---|---|

Product Management | Teams control many SKUs, update inventory and prices fast |

Inventory & Warehouse | RFID tracking, smart sorting, and robots for better work |

Sales Management | Handles orders from many places, links to finance, and helps with customers |

Procurement Management | Adds suppliers, makes orders, and checks rules automatically |

Production Management | Changes schedules, controls BOM, links with MES/CMMS, and uses AI to improve |

Financial Management | Tracks money in and out, and controls costs as things change |

Advanced AI & Industry 4.0 | Shares data right away, plans fixes, and helps make smart choices |

Note: WarpDriven’s cloud erp makes all parts talk to each other in real time, so data and work stay together.

Smart Inventory & Warehouse

Smart inventory and warehouse tools are key for WarpDriven. The platform uses RFID and AI to give real-time stock updates and smooth warehouse work. Companies can see stock in all warehouses. This helps stop too much or too little stock.

WarpDriven’s cloud erp lets teams manage many warehouses around the world. The system moves stock between places, picks items, and uses robots to store things better. AI looks at sales, demand, and shipping to suggest where to put stock and when to refill.

Real-time tracking cuts mistakes and makes things more correct.

Automatic warehouse sorting makes orders faster and deliveries quicker.

Smart guesses help stop too much stock and waste.

Working with shipping partners makes sending and getting goods easy.

Industry stories show real results:

Fast fashion brands had 25% less extra stock and 35% faster deliveries.

Machine makers saved 20% on shipping and turned over stock 30% faster.

Predictive maintenance cut machine downtime by 30%, so they used machines more.

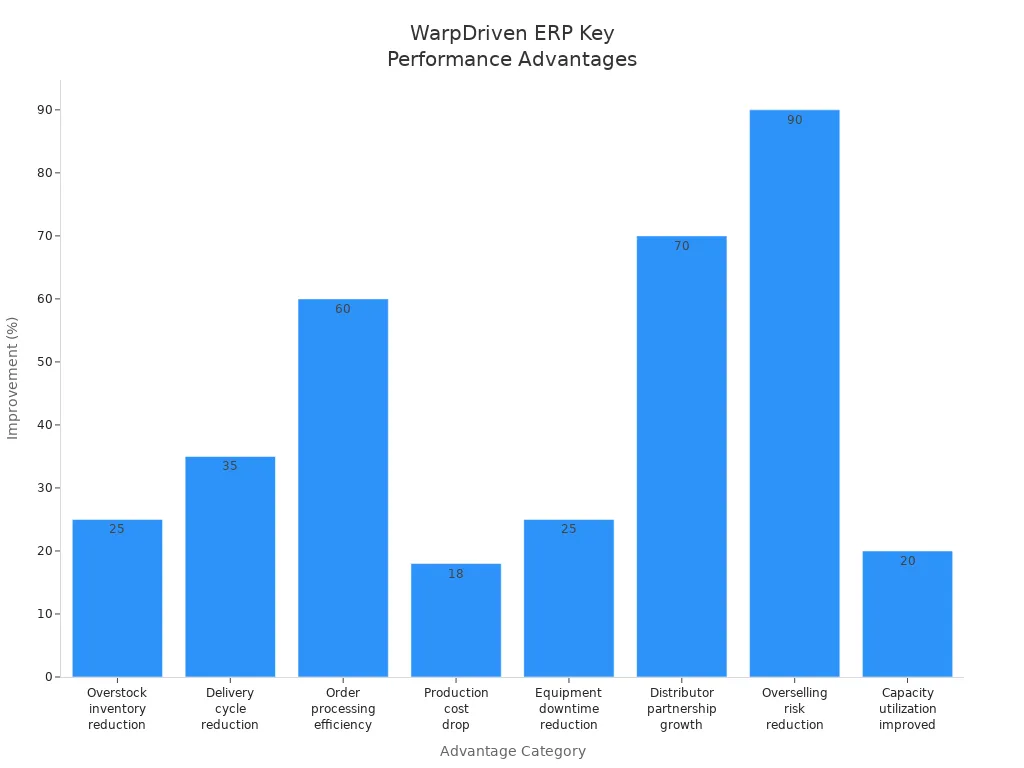

The next table shows how WarpDriven beats old ERP systems:

Key Advantage Category | WarpDriven ERP Feature Highlights | Comparative Performance Improvements (vs. traditional ERP) |

|---|---|---|

Architecture & Integration | Smart PaaS, full-chain data links | N/A |

Product & Inventory Management | Handles many types, RFID real-time updates | Extra stock down by 25% |

Supply Chain & Warehouse | Manages many warehouses, AI sorting | Delivery time down by 35% |

Sales & Procurement | Full process, links to many online shops | Order speed up by 60% |

AI-Driven Operations | Makes choices on its own, guesses demand, sorts warehouses smartly | Production costs down 18%; machine downtime down 20-30% |

Market & Ecosystem Integration | Many languages, currencies, and influencer links | More partners (+70%), less overselling (down 90%) |

Production Efficiency | Better use of machines and time | Machine use up by 20% |

WarpDriven’s cloud erp uses AI to help companies do better. Smart planning, machine fixes, and warehouse sorting save money and speed up deliveries. The erp integration makes supply chain, production, sales, shipping, and finance work as one team.

Companies using WarpDriven see faster orders, quicker deliveries, and lower stock costs.

WarpDriven’s special tools help with tough jobs in fashion, medicine, and global shipping. The platform handles many product types, links to online shops, and uses flexible shipping. These tools help companies work better, change with the market, and win against others.

The chart above shows WarpDriven’s big wins over old ERP. Order speed is up 60%, delivery time is down 35%, and extra stock is down 25%. These numbers show how cloud erp and erp integration can change supply chains.

WarpDriven Supply Chain ERP is a top supply chain tool. It mixes smart AI, smooth erp integration, and special features for each industry to give real value.

Future-Ready Supply Chain Solution

Cloud ERP Integration

WarpDriven is ready for the future because it uses advanced cloud erp integration. The platform brings supply chain, production, sales, logistics, and finance together. Teams can see real-time data from anywhere on any device. Cloud erp helps with many warehouses, many sales channels, and easy erp integration with global partners. This makes it easy for businesses to change fast when the market changes.

Cloud erp integration lets companies grow without slowing down. They can add new features, partners, or places as they get bigger. The cloud design keeps costs low and stops the need for big upgrades.

Key scalability features are:

Following international rules for global business.

Modular setup for adding new features easily.

Real-time tracking with GPS, IoT, barcodes, and RFID.

Automation for faster picking, packing, and shipping.

Unified erp integration for sales, inventory, and finance data.

These features help WarpDriven support growth, save money, and keep customers happy.

Digital Transformation

WarpDriven helps companies go digital by using Industry 4.0 standards. The cloud erp platform keeps product, inventory, and logistics data updated all the time. AI-assisted design and demand forecasting use world data to make better inventory and special products for each area. Connecting with MES and CMMS systems helps with smart production planning and fixing machines before they break.

Full-chain teamwork lets data move from design to delivery, so there is less manual work and better use of resources. The smart AI engine automates product management and inventory plans, making WarpDriven a top supply chain solution for digital change.

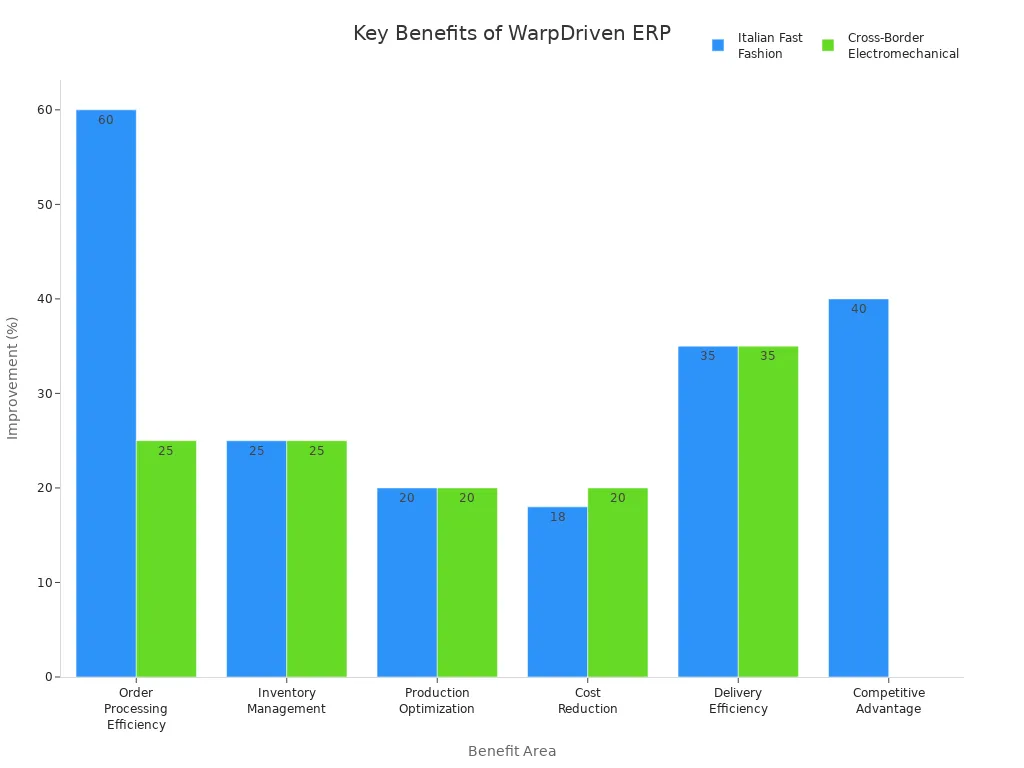

The table below shows real results from two industries:

Benefit Area | Italian Fast Fashion | Cross-Border Electromechanical Products |

|---|---|---|

Order Processing Efficiency | Delivery lead times reduced by 25% | |

Inventory Management | Overstock down 25%, overselling risk down 90% | Unsold inventory down 25%, turnover up 30% |

Production Optimization | Capacity use up 20% | Production efficiency up 20%, OEE up 15% |

Cost Reduction | Production costs down 18% | Transport costs down 20%, maintenance down 25% |

Delivery Efficiency | Delivery cycles shortened by 35% | Delivery cycles shortened by 35% |

WarpDriven’s cloud erp and erp integration help companies get ready for the future. Businesses get faster, more flexible, and have the tools they need for digital change.

WarpDriven Supply Chain ERP helps companies with smart AI and easy connections. It has special tools for different industries. These features help companies work better. For example, order processing is 60% faster. Delivery times are 35% shorter. The table below shows how WarpDriven is better than old ERP systems:

Aspect | WarpDriven Features & Benefits | Case Study Outcomes |

|---|---|---|

AI-Driven Real-Time Adaptation | Dynamic data, autonomous decisions | 60% faster orders, 18% lower costs |

Full-Chain Data Integration | Unified supply chain, production, sales, logistics, finance | 35% shorter delivery, 20% higher efficiency |

Customization & Modularity | Modular design, multi-variant management | Eliminated inconsistencies, faster product launches |

You can talk to the WarpDriven team for a demo.

Email them at info@warp-driven.com.

Try the platform and start making your supply chain better today.

FAQ

What industries benefit most from WarpDriven Supply Chain ERP?

WarpDriven helps many industries like fashion, food, electronics, and manufacturing. Companies with tricky products or global supply chains get the most help. Fast-changing markets also see big improvements.

How does WarpDriven improve order processing speed?

The platform uses real-time data and AI automation. Teams finish orders 60% faster by cutting out extra steps. Information is shared quickly between departments.

Can WarpDriven handle multiple warehouses and global operations?

Yes. WarpDriven manages many warehouses all over the world. The system tracks inventory, moves stock, and works with different currencies and languages.

Is WarpDriven customizable for unique business needs?

WarpDriven has special modules for each industry and flexible workflows. Companies can change features, reports, and connections to fit their needs.

What measurable results have companies achieved with WarpDriven?

Companies say order processing is 60% faster and delivery cycles are 35% shorter. Overstock is down by 25%. These changes help save money and make customers happier.

See Also

Top Brands Expanding Rapidly Using WarpDriven Distribution Solutions

The Role Of Distribution Management In Driving Global Success