B2B fulfillment in 2025 will transform as companies embrace automation, sustainability, and rapid delivery. Hyperlocal fulfillment centers, robotics, and AI-driven inventory management are reshaping expectations. Companies see customer demands shift, with 41% of global shoppers wanting delivery in 24 hours and 75% of B2B buyers preferring online deals for convenience. Greater investment in digital transformation, such as RFID and data analytics, improves order speed and accuracy. Sustainability efforts, like biodegradable packaging, and risk management strategies play a vital role in future-ready B2B fulfillment. Adaptation now ensures long-term competitiveness.

Drivers of Change

Technology Shifts

B2B fulfillment in 2025 will rely on advanced technology to meet rising expectations. Companies now use automation, robotics, and AI-powered systems to improve speed and accuracy. Automated picking, packing, and sorting systems help reduce errors and boost efficiency. Many businesses use RFID tags and IoT devices to track inventory in real time. These tools give clear visibility from order to delivery. Third-party logistics providers offer access to these technologies, making it easier for startups and small businesses to compete. Real-time supply chain transparency, blockchain, and seamless ERP integration also support better decision-making in b2b logistics.

Automation and robotics streamline warehouse operations.

AI-driven forecasting helps manage inventory and reduce waste.

IoT sensors and RFID tags provide real-time tracking.

Blockchain ensures data security and transparency.

Customer Demands

B2b buyers expect fast, flexible, and reliable service. Many want same-day or next-day delivery. They value transparency and want to see stock levels, prices, and delivery times without contacting sales teams. Real-time tracking and inventory management tools help meet these needs. Buyers also look for seamless experiences across online and offline channels. Personalized communication and rapid responses build trust and satisfaction. Companies must adopt digital tools and omnichannel strategies to keep up with these demands in b2b fulfillment.

Note: 84% of b2b customers value consistent interactions across all channels, making omnichannel service a top priority.

Regulations

Regulations shape how companies handle b2b fulfillment. Customs authorities now use advanced analytics to check import and export documents. This raises compliance demands for business procurement teams. New environmental tariffs, like the Carbon Border Adjustment Mechanism, require companies to track emissions and show supply chain transparency. Trade agreements and tariffs change often, affecting costs and supply chain strategies. Stricter data privacy laws, such as GDPR, add more rules for handling shipment data. Many companies partner with third-party providers to manage these complex requirements and stay compliant.

Customs scrutiny increases compliance needs.

Trade agreements and tariffs drive supply chain changes.

Data privacy laws demand secure data handling.

Digital Transformation

AI and Automation

AI and automation now drive a new era in b2b fulfillment. Companies use these tools to streamline procurement, reduce manual errors, and improve supplier collaboration. Many decision-makers focus on AI-driven insights for procurement. In fact, a 2025 Amazon Business study shows 64% of leaders now prioritize these insights, and 90% plan to use AI agents soon. Digital procurement adoption helps teams work faster and more accurately.

Warehouse operations benefit from advanced automation. Robotics and automated guided vehicles (AGVs) handle picking, packing, and sorting. Walmart uses AI-driven warehouse management to cut picking and packing times by optimizing stock placement. Academic research finds that AI-powered systems can boost fulfillment efficiency by up to 30%. DHL’s AI tracking system improves delivery accuracy by 20% and solves delays before they happen. AI job optimization reduces the number of locations visited during picking and packing by 40%, leading to up to 58% efficiency gains. These improvements help b2b companies achieve perfect order fulfillment and scale operations without extra staff.

Automation also cuts costs. For example, a manufacturing client reduced transportation costs by 18% with AI route planning. A food distributor increased order accuracy from 96% to 99.8% after using automated inventory and order management. These gains show how b2b fulfillment grows stronger with technology.

Smart Order Management

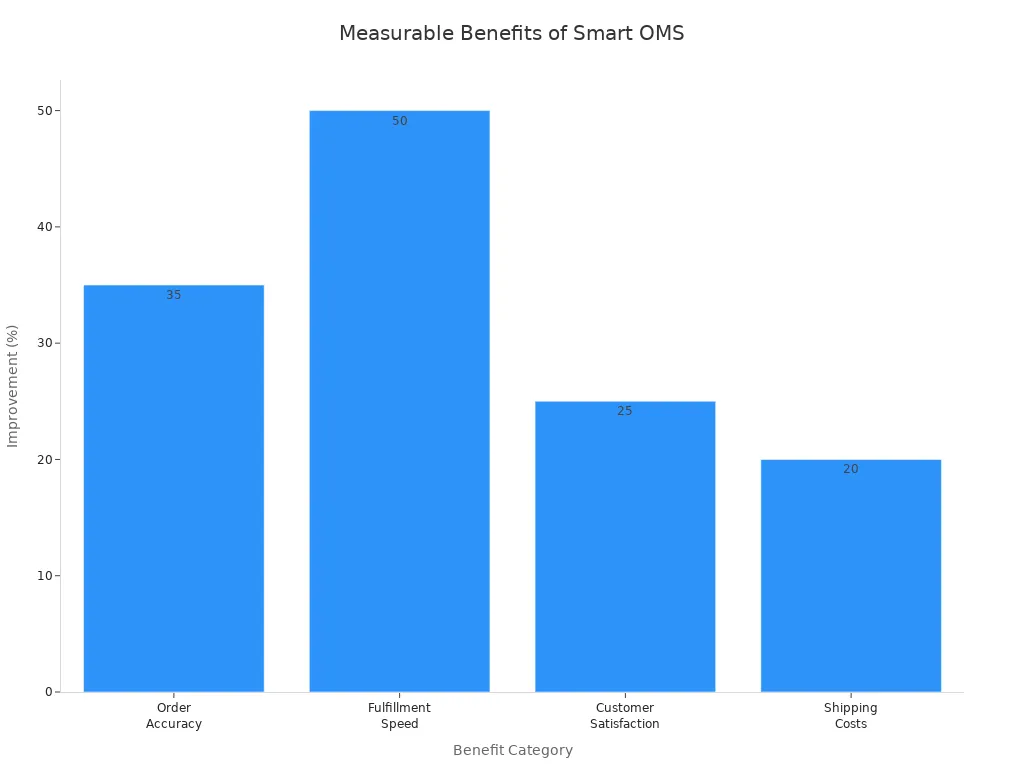

Smart order management systems transform b2b fulfillment by automating order processing and providing real-time inventory updates. These systems validate orders, route them efficiently, and prevent errors. Companies see a 35% increase in order accuracy and process orders 50% faster. Customer satisfaction rises by 25% due to faster delivery and better tracking. Shipping costs drop by 20% as smart routing finds the best carriers and routes.

Labor costs decrease because automation handles repetitive tasks. Inventory control improves, preventing overstocking and stockouts. Smart order management supports multi-channel sales, unifying orders from different platforms and reducing errors. These systems also scale easily, handling more orders as b2b e-commerce grows. Integration with ERP, WMS, and CRM systems streamlines workflows and reduces mistakes. Companies that invest in smart order management gain a clear edge in the competitive b2b market.

Outsourcing in B2B Fulfillment

Specialized Providers

Many b2b companies now turn to specialized providers for outsourcing b2b order fulfillment. These providers, often known as third party logistics partners, offer advanced technology, trained staff, and established warehouse networks. Companies choose this path to manage rising labor and real estate costs, which continue to climb each year. They also want to meet customer expectations for fast delivery. In fact, 92% of buyers expect their orders within two to three business days.

Specialized providers help b2b companies handle complex requirements, such as new product lines or smaller order sizes. Manufacturers use third party logistics to reach more customers and serve new sales channels. These providers offer real-time inventory visibility and integration tools, making it easier to track orders and shipments. Control concerns are addressed through service-level agreements and transparency tools.

About 37% of ecommerce companies fully outsource fulfillment, while 60% outsource at least part of the process.

Enterprise-level companies show a 62% outsourcing rate.

55% of companies plan to increase outsourcing in the near future.

Outsourcing b2b order fulfillment allows companies to avoid costs related to hiring, training, and technology investments. Providers handle repetitive tasks efficiently, improving turnaround times and reducing errors.

Scalability

Scalability stands out as a key advantage of outsourcing b2b order fulfillment. Specialized providers can quickly adjust operations to match demand, especially during peak seasons. In-house teams often struggle with sudden spikes, facing bottlenecks and delays. Outsourcing gives companies access to a nationwide warehouse network, enabling faster and more affordable delivery.

Providers scale up or down without large capital investments.

Companies gain access to advanced technology and expertise.

Internal teams focus on core business activities, supporting growth.

Outsourced b2b fulfillment solutions help businesses expand into new markets without heavy infrastructure spending. This flexibility supports sustainable growth and keeps companies competitive as order volumes change.

E-Commerce Integration

Omnichannel Strategies

B2B commerce now relies on seamless integration across multiple sales channels. Companies use unified inventory systems to track products in real time. This approach prevents stockouts and overselling. Integrated order management systems coordinate orders from every channel, making fulfillment faster and more accurate. Businesses centralize data to remove silos and ensure that teams have the same information. This centralization supports better decision-making and improves customer satisfaction.

Companies that adopt omnichannel strategies see faster order processing and fewer errors. Real-time visibility across all channels helps teams respond quickly to changes in demand.

A scalable fulfillment network allows companies to handle more orders during busy periods. Many b2b e-commerce leaders use warehouse management systems and transportation management systems to keep operations smooth. These tools help companies deliver orders quickly and offer flexible delivery options for bulk or specialized orders. Collaboration with logistics partners further enhances efficiency and reliability.

Unified inventory and order management

Real-time data visibility

Scalable fulfillment networks

Flexible delivery options

Marketplace Participation

Marketplace participation transforms how b2b companies expand their fulfillment capabilities. By joining ecommerce marketplaces, businesses gain access to advanced logistics services and technology platforms. These platforms automate shipping, centralize data, and provide real-time updates for every order. Companies can now handle large transaction volumes without increasing costs or staff.

B2B commerce marketplaces also allow businesses to negotiate better shipping rates by pooling demand. Integrated logistics providers manage shipping and returns, making fulfillment more reliable. Some marketplaces offer industry-specific add-ons, such as reverse logistics and subscription-based pricing, to support unique business needs.

A German manufacturer increased lead conversion by 34% after joining a b2b e-commerce marketplace. Another company doubled its shipping volume without hiring more staff.

Marketplace technology enables multi-party order management and detailed tracking. Companies can share inventory across storefronts, meeting demand more efficiently. APIs connect back-office systems, improving overall fulfillment speed and accuracy. These advances make b2b commerce more scalable and responsive to customer needs.

Personalization Trends

Custom Packaging

Custom packaging has become a powerful tool in B2B fulfillment. Companies use branded boxes, custom tape, and personalized inserts to reinforce their brand identity. These elements create memorable unboxing experiences and help build emotional connections with buyers. Even simple touches, like branded tape, turn shipments into moving advertisements and increase brand visibility in crowded markets.

Many businesses choose eco-friendly packaging to align with sustainability goals. This approach builds trust and shows commitment to responsible practices. Custom packaging also protects products better, reducing returns and boosting customer satisfaction. Companies often include tailored materials or notes, which make buyers feel valued and encourage repeat business.

Custom packaging elevates the unboxing experience and triggers positive emotions.

Unique packaging increases social media sharing and word-of-mouth recommendations.

Thoughtful design enhances perceived product value and supports marketing efforts.

61% of buyers are more likely to reorder when they receive products in premium packaging. Personalized packaging elements foster loyalty and drive satisfaction.

Tailored Delivery

Tailored delivery options set leading B2B companies apart. Buyers now expect rapid shipping, real-time tracking, and flexible delivery options that fit their schedules. Companies meet these demands by partnering with advanced fulfillment providers and using technology to offer choices like same-day, next-day, or scheduled delivery.

Aspect | Operational Challenges | Benefits |

|---|---|---|

Buyer Requirements | Complex demands, rapid delivery, real-time tracking, EDI compliance, diverse shipment sizes | Stronger relationships, reliability, long-term contracts |

Logistical Complexities | Supply chain disruptions, transportation bottlenecks, regulatory compliance, cost management | Competitive advantage, new client attraction |

Cost Management | High costs from expedited shipping, chargebacks, inventory imbalances | Increased revenue from repeat and bulk orders |

Technology Integration | Need for seamless integration with ERP, inventory, and EDI systems | Efficiency via advanced tech and automated fulfillment |

Flexibility & Scalability | Managing demand fluctuations, adapting to order size variations | Flexibility and scalability through 3PL partnerships |

Customer Service | Meeting B2C-like expectations, 24/7 support, consultative services | Enhanced reputation, industry credibility |

Companies that offer tailored delivery improve customer satisfaction by meeting unique needs and reducing delays. Flexible delivery options also help businesses scale quickly and adapt to changing demand. Advanced fulfillment systems and strong logistics partnerships enable these services, ensuring buyers receive accurate and timely deliveries.

Personalization in fulfillment, from packaging to delivery, fosters loyalty and repeat business by delivering relevant and seamless experiences.

Sustainability

Green Logistics

Green logistics has become a core focus for B2B fulfillment leaders. Companies now optimize transportation routes to cut fuel use and lower carbon emissions. Many switch to electric trucks or use biofuels, which helps reduce their environmental impact. AI-driven transport systems, such as those that combine sea and rail, can lower carbon emissions by up to 40%. Decentralizing warehouses and storing goods closer to customers also reduces the need for long-distance shipping and high-carbon air freight.

Many warehouses now use renewable energy and energy-efficient technologies like LED lighting and solar panels. These changes not only help the environment but also lower operating costs. Companies that adopt green logistics improve their brand image and meet new regulations. They also gain better supply chain reliability and reduce logistics costs.

Companies that follow the 3Rs—Reduce, Reuse, Recycle—see improved efficiency, cost savings, and a stronger reputation.

Eco Packaging

Eco packaging is another key part of sustainable fulfillment practices. Many companies use recyclable, biodegradable, or compostable materials to reduce waste. Right-sized packaging and minimalist designs help cut down on material use and shipping costs. Amazon’s "Frustration-Free Packaging" program shows how using recyclable materials and smart design can lower waste and improve customer satisfaction.

Adopting eco-friendly packaging may cost more at first, but it leads to long-term savings. Companies spend less on materials, shipping, and waste management. They also meet customer demand for responsible business and comply with new regulations. Staff training and clear sustainability goals help companies make the switch smoothly.

Eco Packaging Strategies | Benefits |

|---|---|

Recyclable or compostable boxes | Less waste, lower disposal costs |

Right-sized packaging | Reduced shipping costs, less material |

Supplier collaboration | Consistent sustainability across supply |

Employee education | Better adoption, ongoing improvements |

Companies that set clear targets and track progress see the best results from their sustainability efforts.

Precision in B2B Order Fulfillment

Accuracy

Accuracy stands as a core pillar in b2b order fulfillment. Companies use advanced technology and clear processes to reduce mistakes and deliver the right products every time. AI-powered automation now handles order recognition, validation, and processing. This reduces manual errors and speeds up order management. Many businesses set clear objectives for accuracy and share these goals with their teams. They also reward top performers to encourage careful work.

Proper inventory management and warehouse slotting help prevent picking errors. For example, companies separate similar-looking items and organize inventory for easy access. Technology such as voice picking, Pick to Light, and AI cameras further improve accuracy. These tools guide workers and catch mistakes before orders leave the warehouse.

Companies track their progress using key performance indicators (KPIs). The table below shows common metrics for measuring accuracy in b2b order fulfillment:

KPI Category | KPI Name | Description | Relevance to Order Accuracy Improvement |

|---|---|---|---|

Speed KPIs | Order Cycle Time | Time from order placement to shipment | Faster processing reduces errors and improves satisfaction |

Quality KPIs | Orders delivered without errors in product or paperwork | Direct measure of accuracy and quality | |

Customer KPIs | CSAT | Customer satisfaction with service | Shows impact of accuracy on customer experience |

Financial KPIs | Claims/Write-offs | Financial losses from order errors | Tracks cost impact of inaccuracies |

Tracking these KPIs helps companies spot problems and improve their b2b fulfillment operations.

Reliability

Reliability in b2b order fulfillment means customers receive their orders on time and in full. Companies use several strategies to ensure dependable service. Automation of order processing reduces manual mistakes and speeds up workflows. Advanced warehouse management systems (WMS) provide real-time inventory tracking and optimize warehouse operations. Strategic inventory management, such as demand forecasting and velocity-based placement, helps avoid stockouts and overstocking.

Many businesses partner with reliable fulfillment centers and logistics providers. These partners bring expertise and advanced technology. Streamlined logistics and optimized delivery routes lower costs and improve delivery times. Transparent customer communication, including real-time updates, builds trust and keeps buyers informed.

Key processes for reliability include:

Using WMS to automate tasks and prevent errors

Investing in skilled IT teams for quick system fixes

Planning for peak demand and seasonality

Adapting to unique product needs, such as expiration dates

Locating warehouses near customers for faster shipping

Reliable b2b order fulfillment builds strong customer relationships and supports long-term growth.

Future of Fulfillment: Risk & Resilience

Trade Tensions

Trade tensions and rising tariffs continue to reshape the future of fulfillment. Companies now move away from large, seasonal ocean freight shipments. They prefer smaller, agile, order-driven shipments. This approach helps defer tariffs and lowers risk. Many businesses adopt automation and integration to simplify cross-border operations. Delivered duty paid (DDP) models are gaining popularity because they improve cost predictability.

Air freight is becoming more common. It offers speed and growing cost competitiveness. This shift helps companies meet higher expectations for fast, transparent, and flexible service. The changing tariff landscape and complex regulations make agility and automation essential. Merchants and third-party logistics providers (3PLs) now use dynamic fulfillment solutions to stay competitive.

Companies source from China using smaller shipments to delay tariffs and improve cash flow.

3PLs offer tariff-aware fulfillment, automated customs clearance, and flexible routing.

Hybrid B2B2C fulfillment models blend B2B and B2C strategies for real-time demand response.

Automation and integration close the gap between B2B and B2C logistics, enabling faster shipping and better visibility.

These changes mark a permanent shift in the future of fulfillment. Businesses must stay alert and adapt quickly to global trade volatility.

Supply Chain Risks

Supply chain risks are growing in the future of fulfillment. Companies face threats from economic shifts, natural disasters, political instability, and ethical concerns. To build resilience, they use several strategies:

Integrate B2B and D2C fulfillment on a single platform for flexible shipping.

Diversify suppliers across regions, including nearshoring, to reduce disruption risks.

Shift from Just in Time to Just in Case inventory, using safety stock and predictive forecasting.

Explore nearshoring to cut lead times and increase flexibility.

Use digital tools like IoT, AI, and real-time analytics for better visibility and proactive risk management.

Maersk and Deloitte highlight three pillars for resilience: proactive risk management with real-time data, pre-emptive solutions like backup suppliers and flexible routes, and strong partnerships with key suppliers. Companies also map their supply chains, plan for scenarios, and focus on ethical sourcing. The future of fulfillment depends on supply chain innovation and the ability to recover from disruptions. Businesses that invest in these areas will ensure continuity and long-term success.

Future-Proofing Strategies

B2B fulfillment leaders must act now to stay ahead in a changing market. Future-proofing strategies help companies adapt, reduce risk, and drive business success. Two key areas stand out: technology investment and team upskilling.

Technology Investment

Smart technology investments set the foundation for long-term growth. Companies that invest in automation, real-time data, and scalable systems gain a clear edge. These tools improve speed, accuracy, and customer satisfaction.

Actionable steps for technology investment:

Adopt smarter order routing: Dynamic systems select the best warehouse or supplier based on inventory, shipping costs, and customer location. This reduces shipping costs and speeds up delivery.

Implement real-time inventory visibility: Live data prevents stockouts and overstock. Sales teams can give accurate delivery estimates, which builds trust with customers.

Use scalable warehouse management systems (WMS): These systems improve accuracy, maximize space, and boost labor productivity.

Integrate unified order management: Scalable EDI and cloud-based platforms handle high-volume orders from multiple channels. Centralized visibility supports growth without extra staff or infrastructure.

Invest in automation: Voice-picking and modular pack-and-ship solutions cut manual labor and remove bottlenecks. These upgrades lower costs and increase throughput.

Tip: Companies that optimize order routing and inventory visibility have reduced fulfillment costs by 20% and increased on-time deliveries. This improvement often leads to longer-term contracts and stronger customer relationships.

Technology investments deliver value beyond cost savings. They improve customer satisfaction, enhance brand reputation, and boost employee morale. Companies should measure ROI over three to five years, tracking metrics like order accuracy, processing speed, and customer feedback. Continuous tracking and optimization ensure the best results.

Technology Focus | Benefit |

|---|---|

Smarter order routing | Lower shipping costs, faster delivery |

Real-time inventory visibility | Fewer stockouts, better cash flow |

Scalable WMS | Higher accuracy, better productivity |

Automation | Reduced labor costs, higher throughput |

Unified order management | Efficient multi-channel fulfillment |

Team Upskilling

A skilled team drives fulfillment performance. Upskilling ensures employees can handle new technologies and changing customer needs. Companies that invest in their people see higher retention, better service, and stronger results.

Practical ways to upskill teams:

Offer ongoing training: Regular workshops and courses help employees grow in their roles. Training should match team goals and business needs.

Encourage initiative: Empower team members to make decisions and solve problems. This builds autonomy and sparks innovation.

Promote knowledge sharing: Create spaces for employees to learn from each other. Sharing expertise strengthens the whole team.

Address conflicts quickly: Resolve issues early to keep teams focused and productive.

Develop both hard and soft skills: Teach technical skills for new systems and soft skills like communication and teamwork.

Note: Companies with strong upskilling programs report 76% of employees plan to stay for at least two more years. This stability reduces hiring costs and keeps productivity high.

Upskilling also attracts new talent and develops future leaders. Employees who feel valued and prepared for change show higher engagement and loyalty. A future-ready workforce adapts quickly, maintains service quality, and supports reliable fulfillment.

Upskilling Practice | Impact on Fulfillment Performance |

|---|---|

Ongoing professional development | Higher productivity, stronger teams |

Encouraging initiative | More innovation, faster problem-solving |

Knowledge sharing | Broader expertise, fewer errors |

Conflict resolution | Better team cohesion, steady performance |

Hard and soft skill training | Adaptability, improved customer service |

Pro Tip: Upskilling reduces turnover and builds a workforce ready for rapid change. This is critical for maintaining reliability and service quality in B2B fulfillment.

B2B fulfillment in 2025 will see rapid change driven by technology, sustainability, and rising customer expectations. Companies must act with urgency and embrace innovation to stay ahead. To future-proof operations, leaders should:

1. Modernize technology stacks for seamless integration and automation. 2. Automate shipping and load planning to boost efficiency. 3. Use real-time analytics for smarter decisions. 4. Scale infrastructure for peak demand. 5. Adopt sustainable and right-sized packaging. 6. Invest in employee training and foster a culture of improvement.

Now is the time for every B2B company to review its fulfillment strategy and lead the way in a fast-changing market.

FAQ

What technologies will shape B2B fulfillment in 2025?

AI, automation, and real-time data tracking will lead the way. Companies use smart order management, robotics, and IoT devices to boost speed and accuracy. These tools help businesses meet rising customer expectations and improve efficiency.

Why do companies outsource B2B fulfillment?

Outsourcing gives companies access to advanced technology, skilled staff, and flexible warehouse networks. This approach helps manage costs, scale operations quickly, and focus on core business activities.

How does sustainability impact B2B fulfillment?

Sustainability drives companies to use eco-friendly packaging and green logistics. Many businesses choose renewable energy and optimize delivery routes. These actions lower costs, meet regulations, and improve brand reputation.

How can companies reduce supply chain risks?

Companies build resilience by diversifying suppliers, using real-time analytics, and keeping safety stock. They also invest in digital tools for better visibility. These steps help them adapt to disruptions and maintain reliable service.

See Also

Top Brands Expanding Growth Using WarpDriven Distribution Solutions

Key Features That Differentiate WarpDriven ERP For Smart Enterprises

The Role Of Distribution Management In Driving Worldwide Business